Advanced Cnc Millined Anodized Aluminum Prototype

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 10 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 10000 Piece/Pieces |

| Supply Ability: | 200000 pieces per Month |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| Certificate: | ISO 9001,ISO 14001 |

| HS Code: | 518100 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

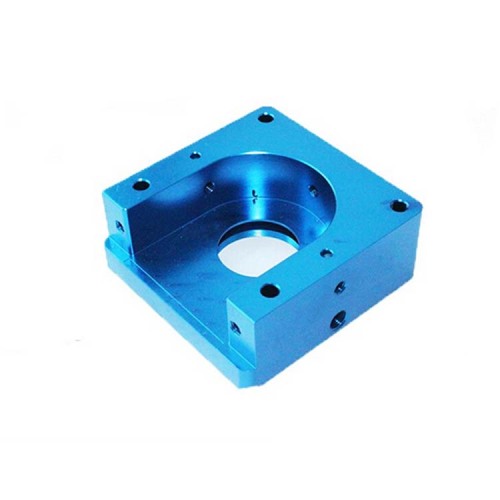

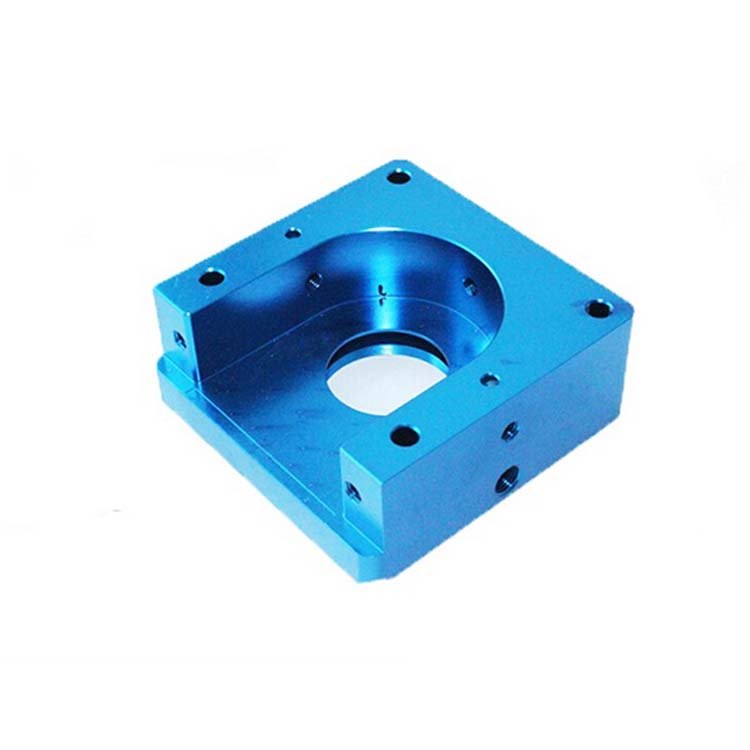

Advanced Cnc Millined Anodized Aluminum Prototype

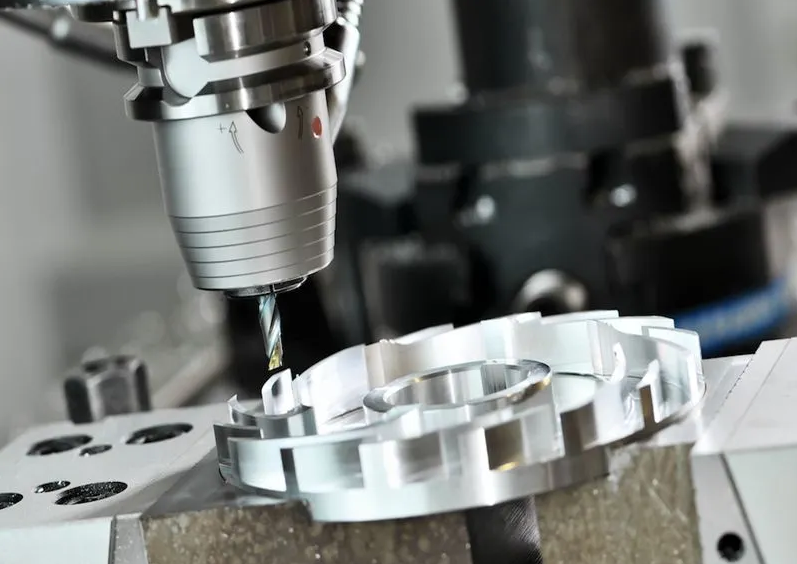

In order to improve the accuracy of the slot width and reduce the number of tool changes, a milling cutter with a diameter 7 wider than the slot can be used for machining. The middle part of the slot is first milled, and then both sides of the slot are milled using the tool size compensation function. When processing three-dimensional curved surfaces or variable beveled contour shapes, ball-end milling cutters, ring milling cutters, drum milling cutters, cone milling cutters, disc milling cutters, etc. are often used. When the machining allowance is small and the surface area is required to be high, a face milling cutter with a panel cubic boron nitride blade or a panel ceramic blade can be selected to brake the machine for high-speed cutting.

We are OEM. Main producetion metal &plastic parts and main business scope is CNC Turning Machining ,CNC Milling Machining,CNC Machining Parts,Plastic Parts,Sheet Metal,Die Casting and so on.

Advanced Cnc Millined Anodized Aluminum Prototype

In order to improve the accuracy of the slot width and reduce the number of tool changes, a milling cutter with a diameter 7 wider than the slot can be used for machining. The middle part of the slot is first milled, and then both sides of the slot are milled using the tool size compensation function. When processing three-dimensional curved surfaces or variable beveled contour shapes, ball-end milling cutters, ring milling cutters, drum milling cutters, cone milling cutters, disc milling cutters, etc. are often used. When the machining allowance is small and the surface area is required to be high, a face milling cutter with a panel cubic boron nitride blade or a panel ceramic blade can be selected to brake the machine for high-speed cutting.

We are OEM. Main producetion metal &plastic parts and main business scope is CNC Turning Machining ,CNC Milling Machining,CNC Machining Parts,Plastic Parts,Sheet Metal,Die Casting and so on.

Product images

Product Information:

Material: Aluminum

Color: Customization

Surface treatment: anodized

Craft: CNC Machining

Tolerance: ±0.01mm

Our Clients

YP-MFG brings many years of experience in supplying customized products from Australia, Canada, Italy, France, Germany, Japan, etc.

Information you need to provide

- 2D or 3D drawing

- material

- surface treatment

- quantity

Free quality inspection service

100% inspection before shipment

After sending, we will track the product for you every two days until you get the product.

After receiving the goods, please test and give me feedback. If you have any questions about the problem, please contact us and we will provide you with a solution.

Contact

100% inspection before shipment

After sending, we will track the product for you every two days until you get the product.

After receiving the goods, please test and give me feedback. If you have any questions about the problem, please contact us and we will provide you with a solution.

Related Keywords