High Demand CNC Turning Machining Brass Nozzle

- Payment Type:

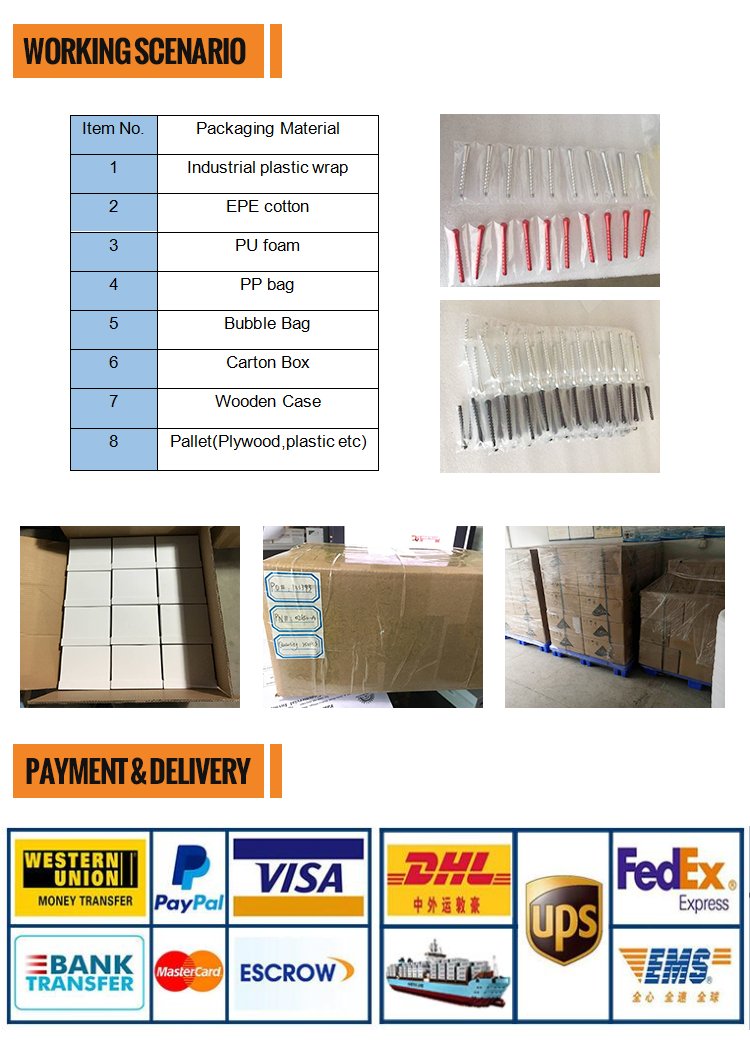

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 500000 Piece/Pieces |

| Supply Ability: | 200000 pieces per Month |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| Certificate: | ISO 9001,ISO 14001 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian |

High Demand CNC Turning Machining Brass 3D Printer Nozzle

3D printers are precision instruments, and they are the same for both industrial and civil applications.Various parts of 3D printers are combined together to play their respective roles, among which the quality of the nozzle largely determines the quality of the printing operation.Nozzles are usually made of brass material and can be electroplated surface.There are many specifications of the nozzle, such as 0.3mm, 0.4mm and 0.5mm. We manufacture and produce according to the customer's drawings,insure reach to their all requirements.Steel Die Casting Parts, Stainless Steel Die Casting,Aluminum Alloy Die Casting,Die Casting Aluminium Part,Die Casting Parts,Die Casting Aluminum,Bending Tube Steel,Bending Stainless Steel Tubing.

|

Product Name |

High Precision CNC Turning Machining Stainless Steel Shaft |

|

Micro machining |

yes |

|

Tolerance |

0.003mm-0.01mm |

|

Surface finish |

Based on customer requirements, we can do Plating(Zinc plated, Nickel plated, Chrome plated,etc), polishing(precision can reach +/-0.005mm), knurling, anodizing, Black Oxide, heat treatment, sandblasting, powder coating, etc. |

|

Precision processing |

turning, milling, drilling, grinding, wire-EDM cutting etc |

|

Material range |

Metal: Stainless Steel, Brass,Copper, Brozone, Aluminum, Steel, Carbon Steel etc. |

|

|

Plastic : PU, PVC, POM, PMMA, Nylon ,HDPE etc. |

|

QC(inspection everywhere) |

- Technicians self-check in production |

|

|

- Engineer spot check in production. |

|

|

- QC inspect after products finished |

|

|

- International sales who were trained the technical know-how spot check before shipping to ensure the quality. |

|

High-Quality |

rich manufacturing experience,competitive price |

Related Keywords