OEM CNC Milling Anodized Aluminum Bike Parts

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 10 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 50000 Piece/Pieces |

| Supply Ability: | 200000 pieces per Month |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| Certificate: | ISO 9001,ISO 14001 |

| HS Code: | 518100 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

OEM CNC Milling Anodized Aluminum Bike Parts

The anode effect is a unique phenomenon of molten salt electrolysis, and the performance of electrolytic aluminum production is still obvious. When the anode effect occurs during production, the cell voltage rises sharply, reaching 20 ~ 50V, sometimes even higher. Its occurrence has a great impact on the entire electrolysis series, reducing the current efficiency, affecting the technical indicators of electrolysis, and reducing the output and quality of aluminum, and destroying the smooth power supply of the entire electrolysis series. There are two treatment methods: extinguish with effect rods (wooden rods), or lower the anode, and increase the amount of aluminum oxide to achieve the purpose of extinguishing the anode effect. So far no better treatment has been found.

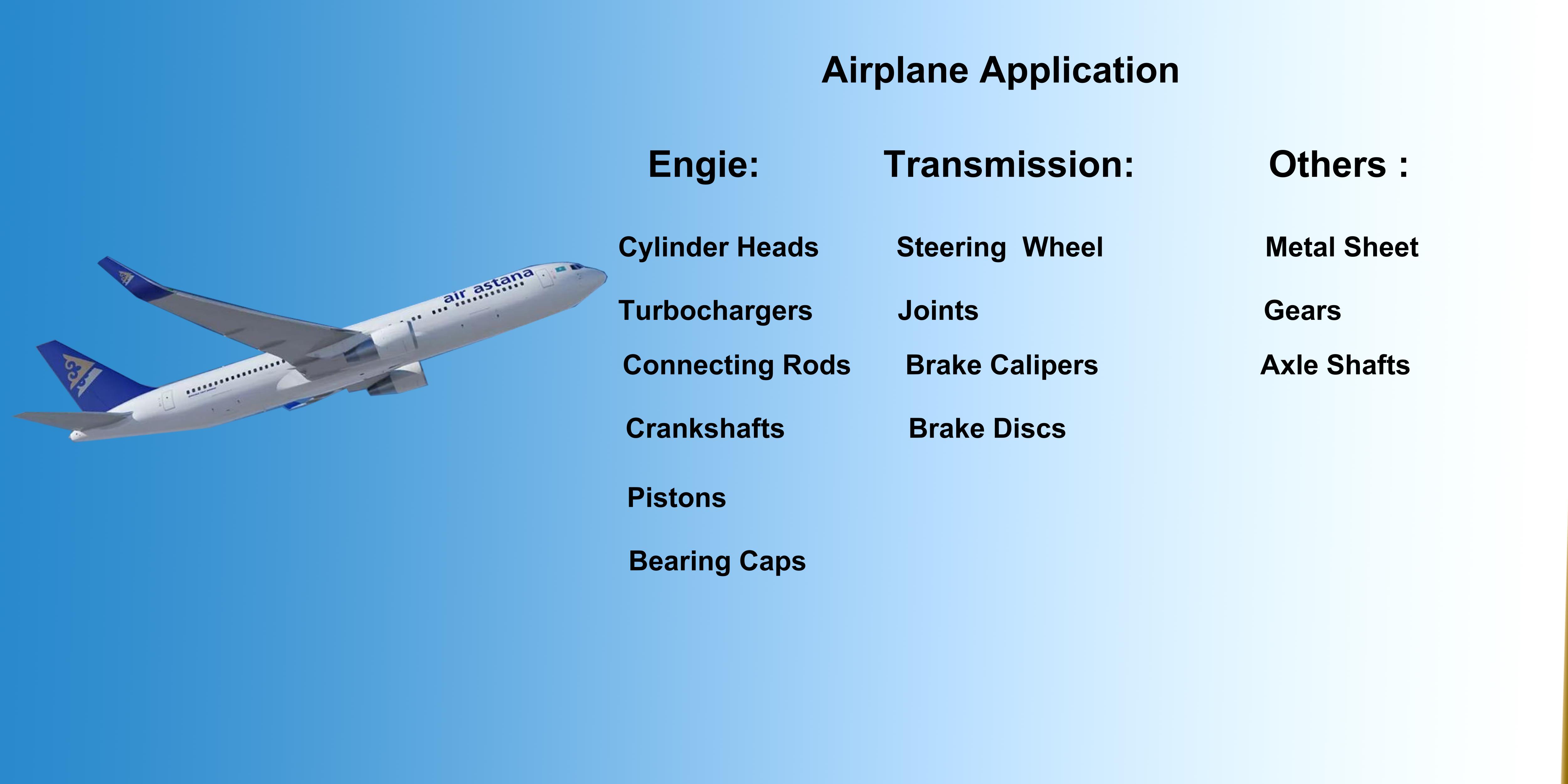

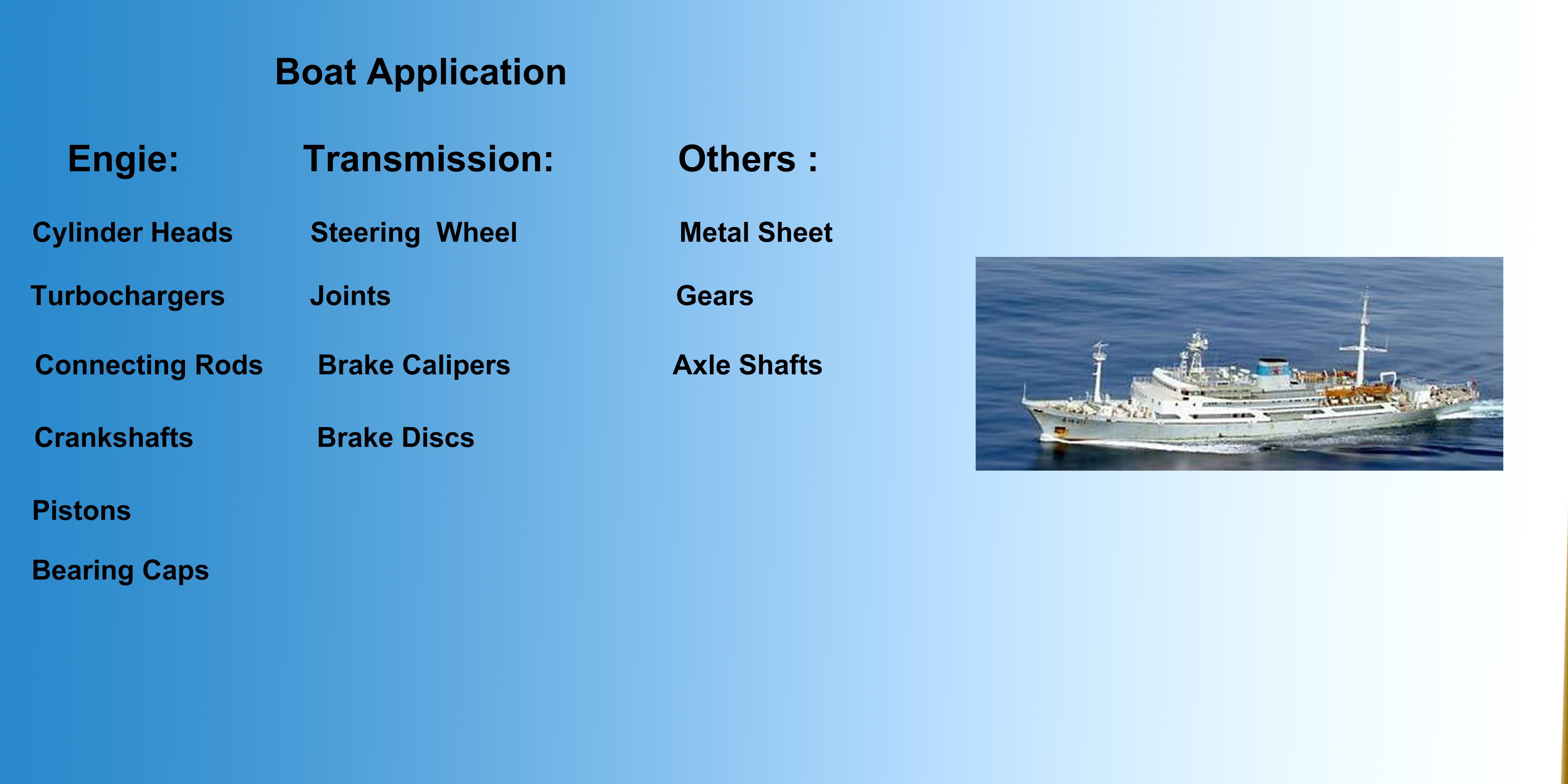

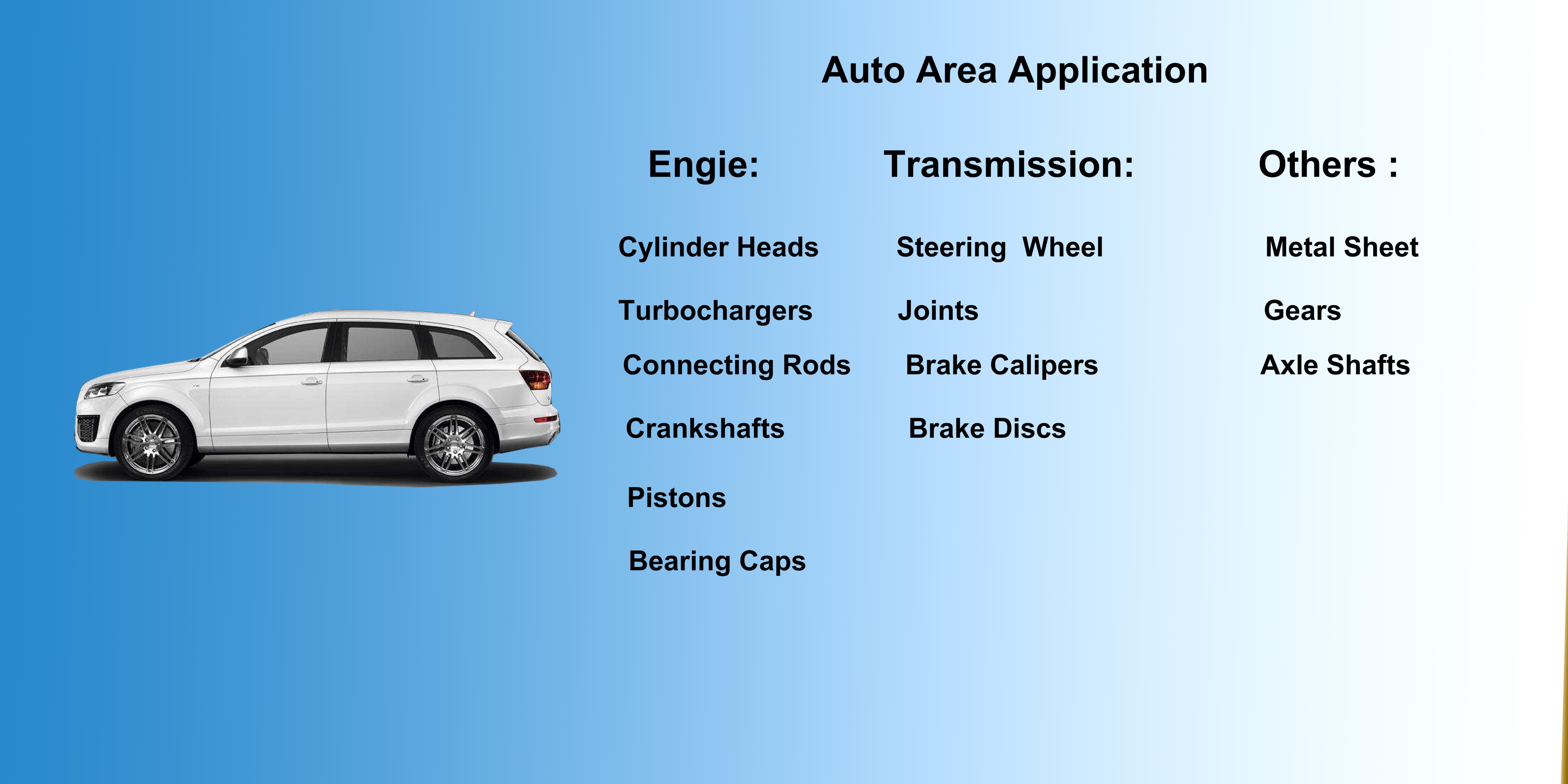

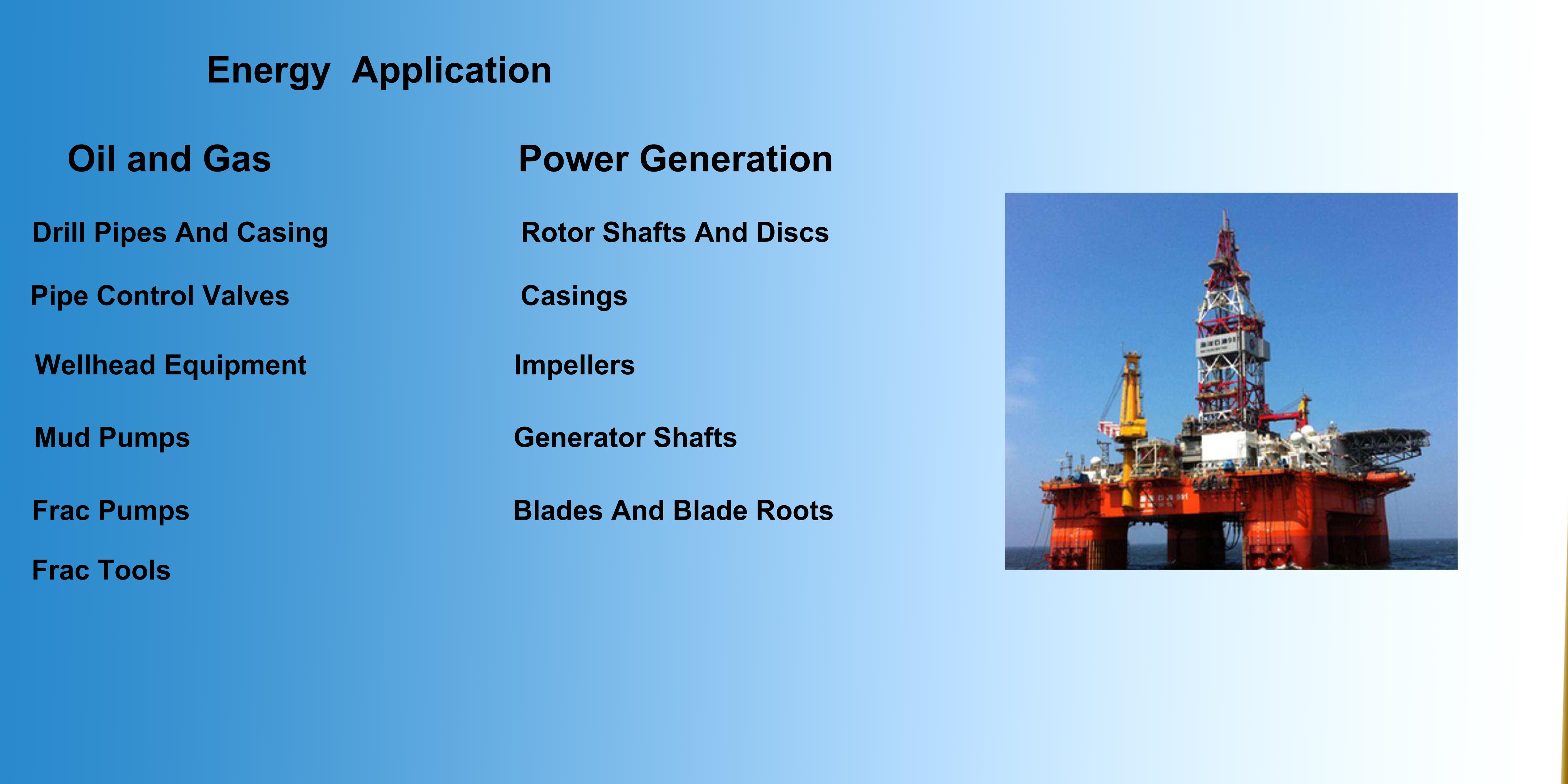

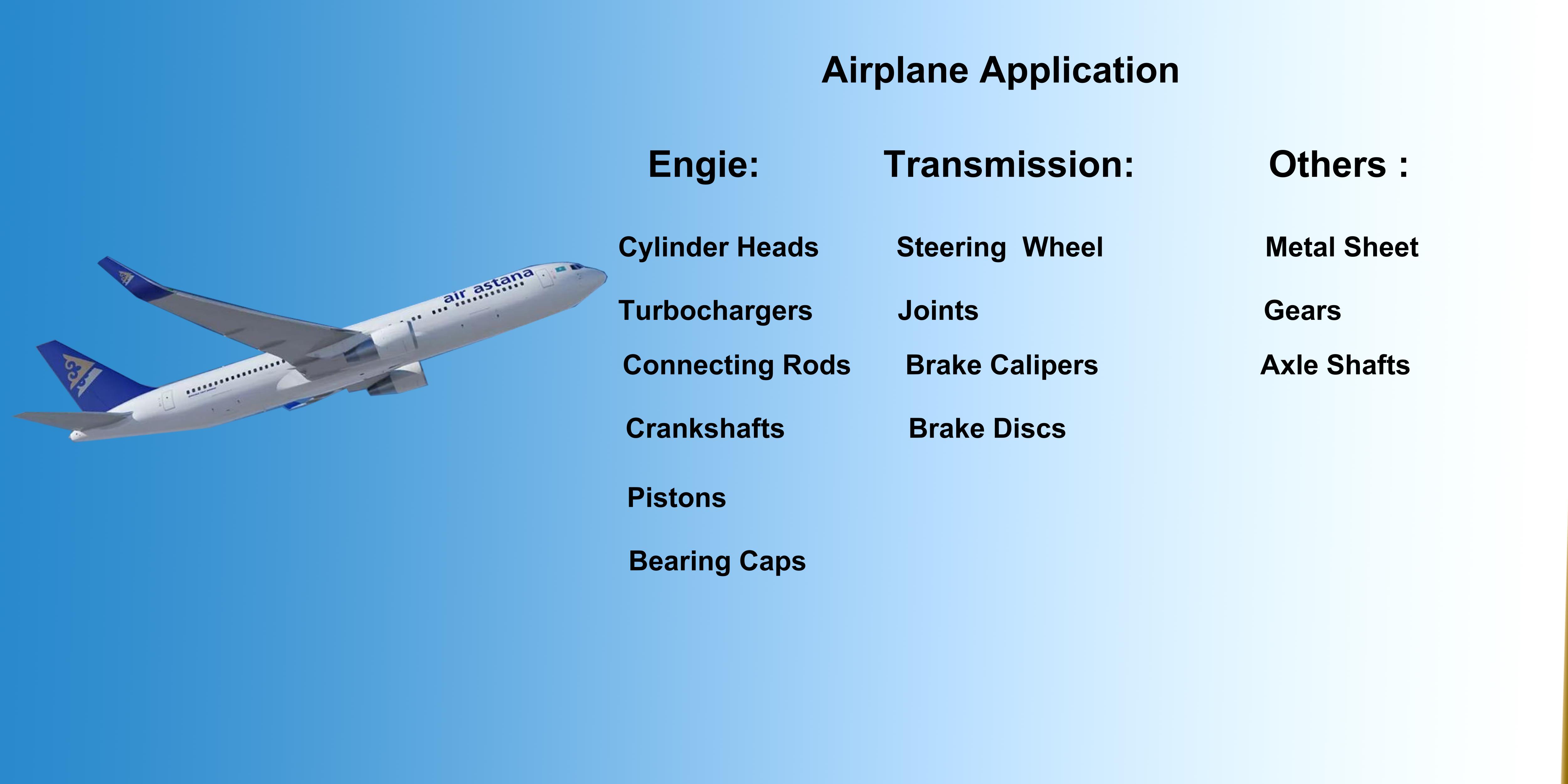

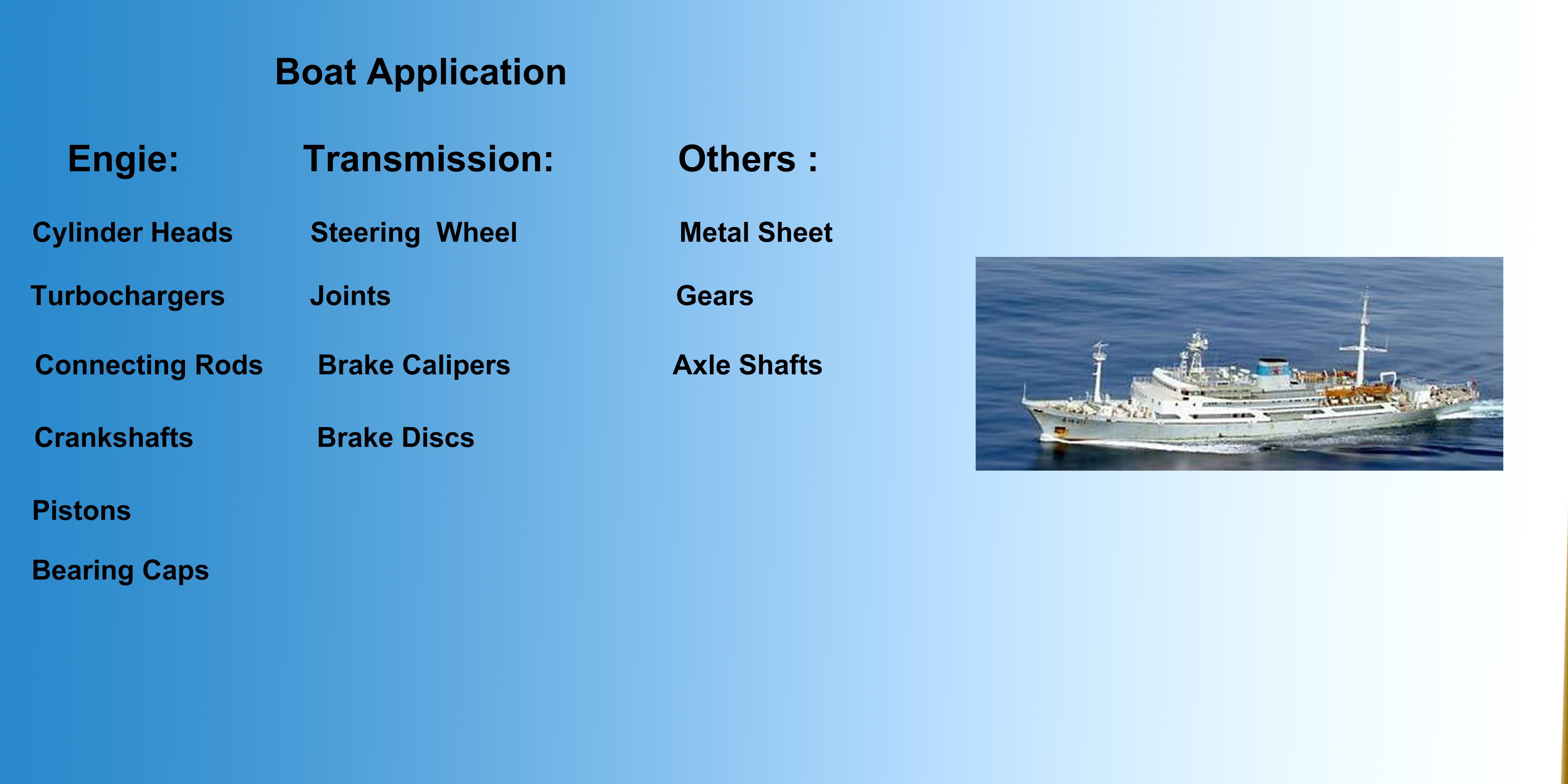

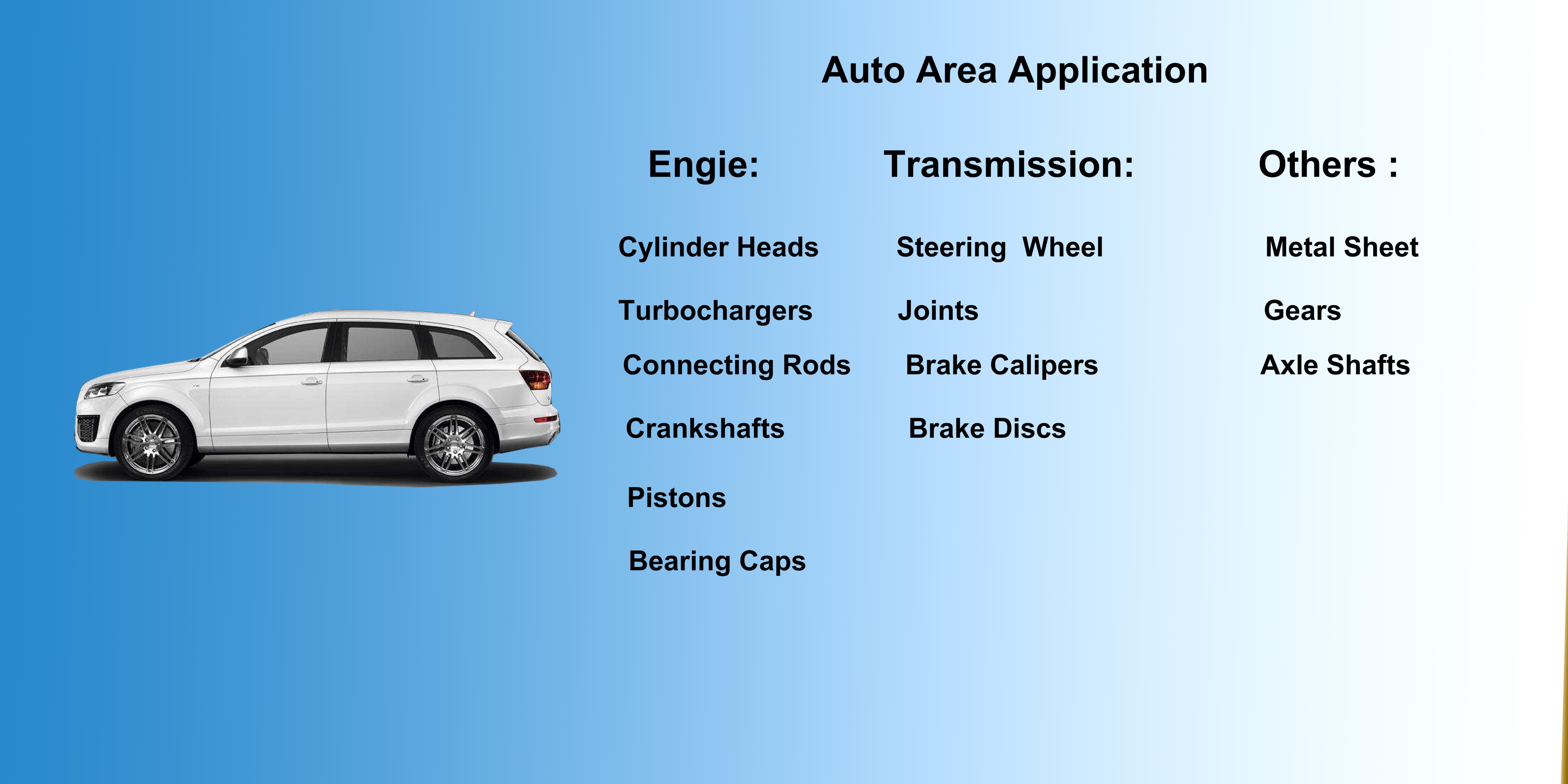

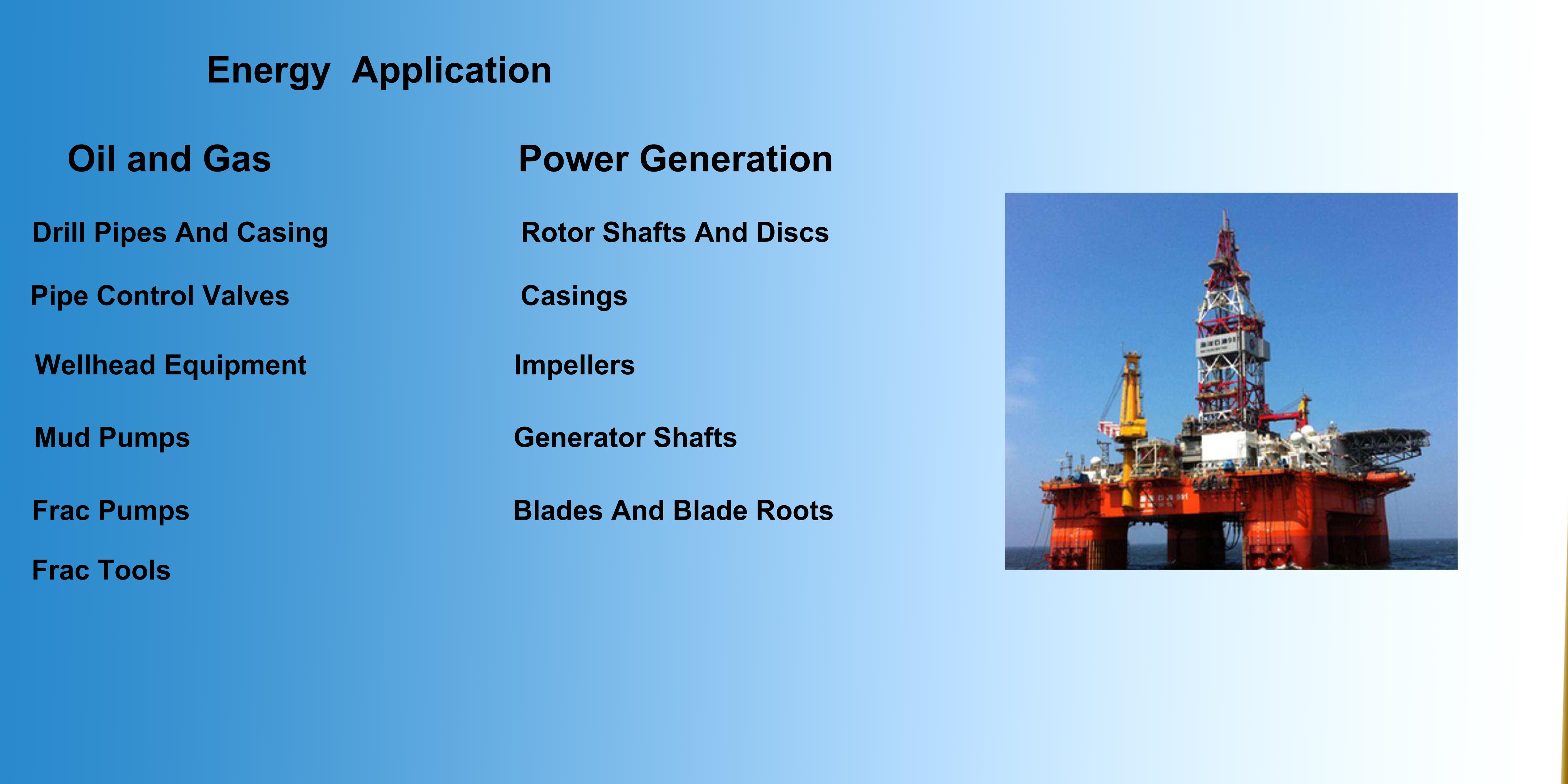

We are OEM. Main producetion metal &plastic parts and main business scope is CNC Turning Machining ,CNC Milling Machining,CNC Machining Parts,Plastic Parts,Sheet Metal,Die Casting and so on.

Material Range

Aluminum,Stainless Steel, Brass,Copper, Brozone, Titanium, Carbon Steel ,Alloy,Plastic etc.

Production Technology

CNC Turning,CNC Milling,Metal Sheet,Stampling,Die Casting,Forging etc.

Surface Finish

Based on customer requirements, we can do Plating(Zinc plated, Nickel plated, Chrome plated,etc), polishing(precision can reach

+/-0.005mm), knurling, anodizing, Black Oxide, heat treatment, sandblasting, powder coating, etc.

Precision Processing

turning, milling, drilling, grinding, wire-EDM cutting etc

Tolerance

0.003mm-0.01mm

+/-0.005mm), knurling, anodizing, Black Oxide, heat treatment, sandblasting, powder coating, etc.

Related Keywords