Plastic car trim cover mold

- Payment Type:

- L/C, T/T, Money Gram, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen Port, Yantian Port, Shekou Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen city,Guangdong province,China |

|---|---|

| Productivity: | 30 sets per month |

| Payment Type: | L/C,T/T,Money Gram,Western Union |

| Incoterm: | FOB,CIF |

| Certificate: | ISO9001 |

| HS Code: | 518118 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen Port,Yantian Port,Shekou Port |

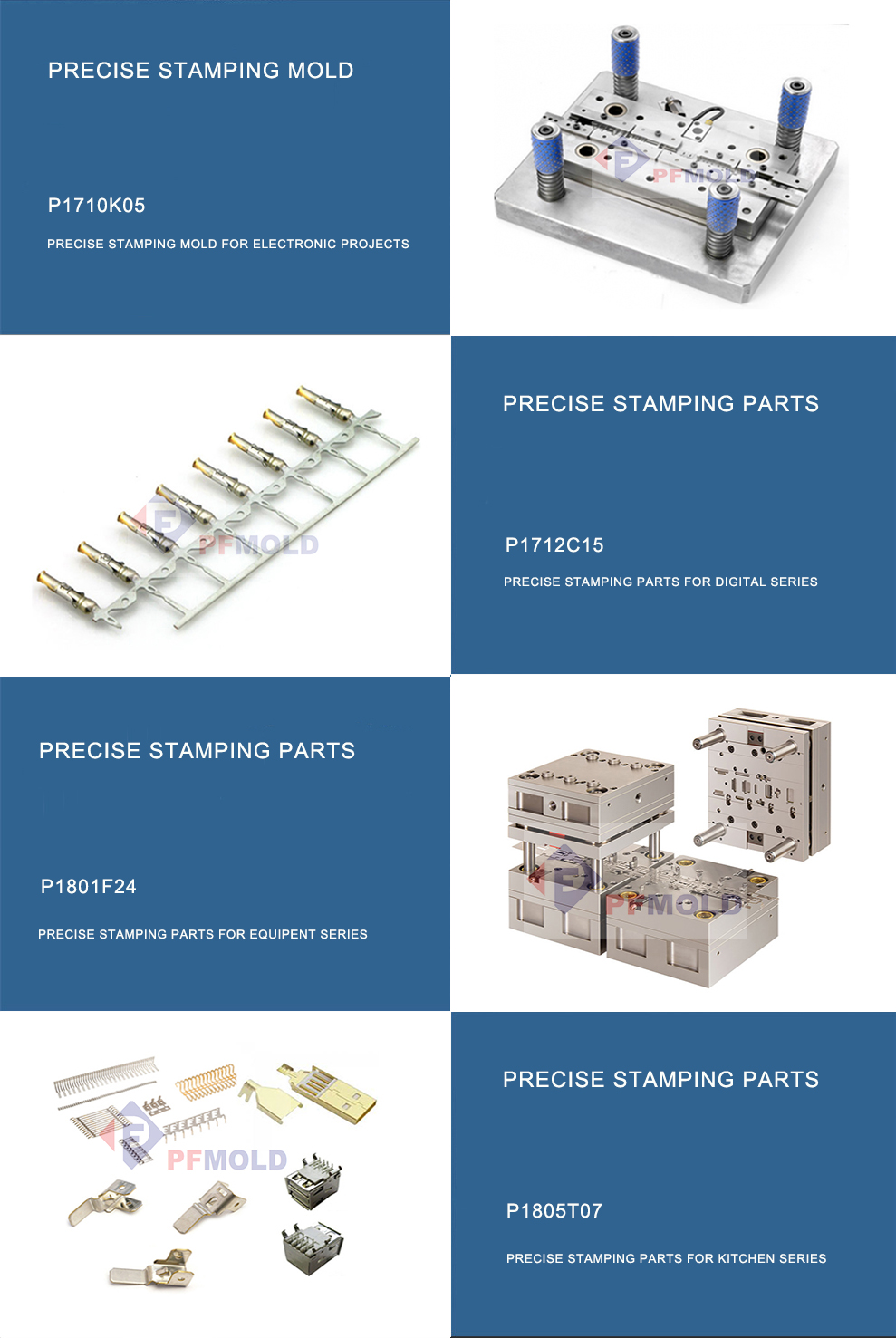

Fine Blanking by progressive die

We offer our customers a [One Stop Shop" when they combine our metal stamping expertise with our in-house Molding for Insert Molding or Assembly. Please click link for more information.works with the customer throughout the entire process including: DESIGN arrow TOOL AND DIE MANUFACTURING arrow MATERIAL OPTIMIZATION arrow ADVANCED QUALITY PLANNING arrow PRODUCTION ASSEMBLY arrow SHIPPING.PFMOLD has over fifty high-speed stamping presses and uses Precision, Bruderer and Minster Presses ranging from 20 to 200 tons.Customized Metal Die,High Precision Stamping Mould, Metal Stamping Punching Mold,Stamping Die Mold For Ceiling.

Tips about metal stamping:

Tips about metal stamping:

With punch press, metal stamping is the process that makes metalsheet transformed into parts with expected size and form.Stamping is cold deformation of metal. Sometimes, it is named as cold stamping or metalsheet stamping.

stamping tooling(metal or non metal) is the special tools for massive production of stampled parts, and it is essentially important.

Stamping, compare to other machining ways, it has quite a few advantages:

1. Higher efficiency and easier process, usually a punch press can stamp dozens of times per minute, some better stamping equipments can stamp hundred or even thousand of times one minute.

2. Higher Precsion and stable quality, toolings ensures precision of size and form of the products,and it can be used for quite a long time, which ensures the stable size and form of products.

3.Stamping can handle parts with more complicated form, from clock parts to longeron of trucks.

4.Stamped parts has very good strength and rigidity.

5. Metal Stamping use less materials, because there is no waste trimmings produced.

6. Enviroment friendly production process, stamping is a cold process, without heating.

Because of the above said good things, metal stamping is widely used in the industries, 80% parts in a wrest watch are stamped parts, Tv set, handy camera 90%.

But one tooling only for one product, sometime, a product needs quite a few sets of tooling, stample tooling requires precision, and technology.

There were setbacks and shortcoming for metal stamping, mainly noise. Nowdays, modern equipment has improved greatly and solving thes problems gracefully.

Products show:

About Us:

Package:

Related Keywords