H910 Off-line AOI machine

-

$1000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

Your message must be between 20 to 2000 characters

Contact Now

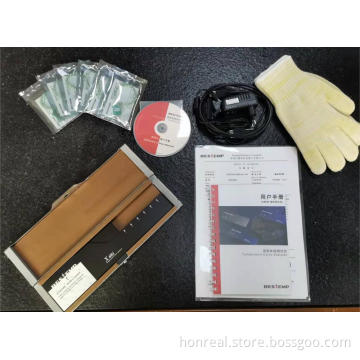

1. H910 Offline AOI machine

AOI may inspect a PCB board with components the following features:

· Area defects

· Billboarding

· Component offset

· Component polarity

· Component presence or absence

· Component Skew

· Excessive Solder Joints

· Flipped component

· Height Defects

· Insufficient Paste around Leads

· Insufficient Solder Joints

· Paste

· Severely Damaged Components

· Tombstoning

· Volume Defects

· Wrong Part

· Solder Bridging

· Presence of Foreign Material on the board

AOI can be used in the following locations in the SMT lines: post paste, pre-reflow, post-reflow, or wave areas.

Function advantage:

1. It is suitable for high-end full-automatic SMT production line and real-time AOI detection.

2. More efficient automation, no manual release, standard NG or OK board signals;

3. A more provincial, one person monitoring multiple AOI detection equipment;

4. It can identify one-dimensional code and qr code reading and query, and realize maintenance workstation.

5. Stable 0201 detection capability, optional 01005 detection function;

6. In front of the furnace, after the furnace and other positions, one machine multi-purpose.

Parameter configuration:

|

category |

project |

specifications |

||||||||||||||||||||||||||

|

Visual identity system |

|

|||||||||||||||||||||||||||

|

Mechanical system |

|

|||||||||||||||||||||||||||

|

Software system |

|

|||||||||||||||||||||||||||

|

Control system |

|

|||||||||||||||||||||||||||

Related Keywords