High-efficiency Centrifugal Blower for Air Pump

- Incoterm:

- FOB

- Delivery Time:

- 10 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 4000sets/month |

| Supply Ability: | 4000sets/month |

| Incoterm: | FOB |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

The centrifugal cooling fan produced by our company can be customized according to customer requirements. The conventional centrifugal blower has 110V, 220V and common current, and the internal structure of ball bearings is adopted.

Applicable scope: centrifugal fan is widely used in factories, mines, tunnels, cooling towers, vehicles, ships and buildings ventilation, dust and cooling; industrial boilers and furnaces ventilation and air conditioning; cooling and ventilation equipment and household appliances in the air; grain drying and selected; wind tunnel wind and hovercraft inflatable and propulsion.

Production description

Centrifugal fan is a mechanism that relies on the input of mechanical energy to increase the pressure of gas and discharge the gas. It is a kind of driven fluid machinery.

The working principle of its centrifugal fan is that centrifugal fan is based on the principle of converting kinetic energy into potential energy, and accelerates the gas with high speed rotating impeller, then decelerates and changes the direction of flow, so that kinetic energy can be converted into potential energy (pressure). In a single stage centrifugal fan, the gas enters the impeller from the axial direction, and the gas flows through the impeller into the radial direction and then enters the diffuser. In the diffuser, the gas changes the direction of the flow and increases the section area of the pipe to slow the air flow, which converts the kinetic energy into the pressure energy. The pressure increases mainly in the impeller, followed by the expansion process. In a multistage centrifugal fan, a reflux is used to make the air flow into the next impeller and produce higher pressure.

Structure Diagram

Product Images

Failure maintenance of centrifugal fan

The wear of the drive parts of the centrifugal fan is a common equipment problem, including the bearing position of the fan, the wear of the bearing chamber, the wear of the shaft bearing of the blower and so on. Aiming at the fault of centrifugal fan, the traditional maintenance method with welding, thermal spraying, brush plating and so on, but there are some drawbacks: welding and high temperature thermal stress generated can not be completely eliminated, causing material damage, causing components to bend or break; and by brush plating coating thickness limit easily, and more than two methods are used to repair metal metal, can not change the "hard to fit hard", in the comprehensive function of the force, will cause the rubber coated roller wear again. In the contemporary western countries, many polymer composites are used to repair the above problems. The application of the technology system in USA is more than that of the USA. It has super adhesive force, excellent compressive strength and other comprehensive properties. It can be dismantled without machine processing. Not only does the welding thermal stress effect, the thickness of repair is not restricted, concession metal products have not have, can absorb shock and vibration equipment, to avoid wear may gradually replace the traditional method used in China for the repair of centrifugal fan.

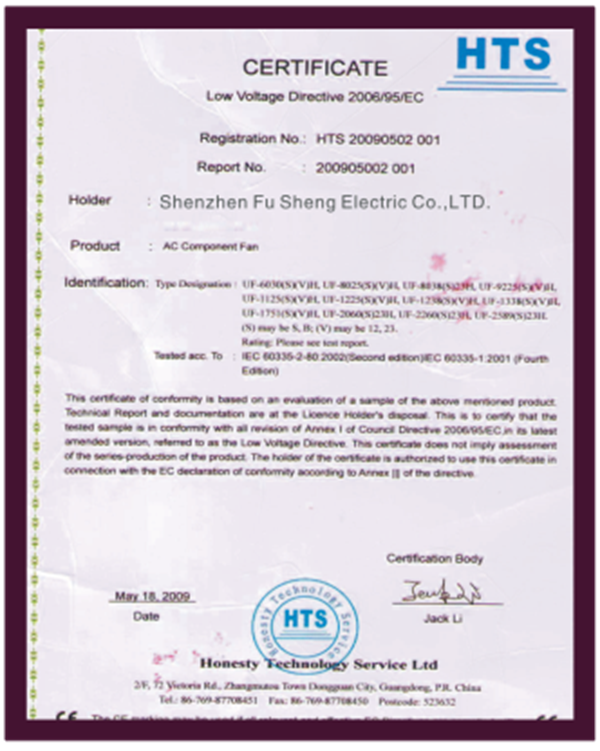

Certification

Our company has been ISO9001-2000 international quality

management system certification as the purpose,

now introduced to the environmental management system.

The products are certified by many countries and regions.

Such as: UL, CCC, TUV, CE and so on.

ABOUT US

Shenzhen Fu Sheng Electric Co.,LTD.is professional manufacturer of DC/AC/EC containing brush less axial compressor,cross current flow,centrifugal cooling fan,it is set up in October 2004 located in the beautiful scenery and developed economy,Shenzhen City,Guangdong Province.We have been working hard in the industry field and the enterprise has been a considerable scale.Because of the advantages of the business philosophy,has been a good product price and quality service to win the market,To win the trust of customers.Our products are widely used in IT field,Sports equipment,ventilation equipment,welding equipment, power systems,medical electronic equipment,machinery and equipment etc.

WHY CHOOSE US?

1.Product diversification, DC, AC, EC full series of brushless axial flow, cross flow, centrifugal fan.

2.14 years of production experience, to provide you with quality assurance.

3.Professional and technical personnel and advanced production equipment.

4.7x24 hours service online, welcome to consult, to provide you with high quality service.

5.Protection of your sales area,ideas of desigen and all your private information.

Packing and Shipment

2.You can choose sea, air, land, and international express, or the mode of transportation according to the customer's request.

3.The delivery time is 7~10 days, according to the quantity of the goods.

Factory and Equipment

Welcome to Shenzhen Fu Sheng Electric Co.,LTD.

Please don't hesitate to contact us for any question!!!

Related Keywords