Normal Plastic Moulded Auto Parts Kinds of Car

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 35 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Western Union |

|---|---|

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

Product Description

Product design and production according to customer requirements. Welcome OEM and ODM.We Can provide prototype.

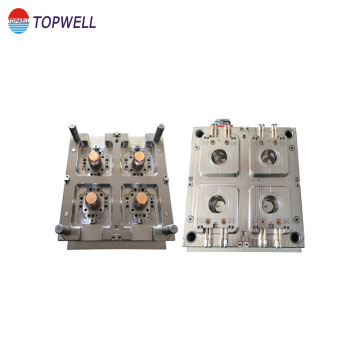

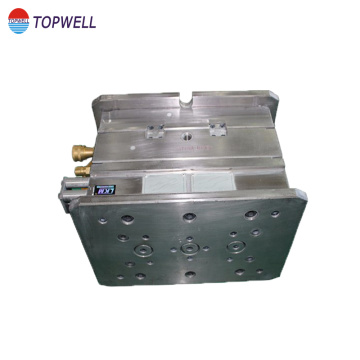

Detailed Image

Details of Mould

Details of Mould

Name

Mould Material

NAK80, S136, 2316, 2738, H13, 718H, 738H, P20, DC53, etc

Product Material

PET,PBT,PPS,PA6/PA12,LCP,PPE+PS,PPI,ABS,PC,ABS+PC,POM,HIPS.

PU,PVC and PP etc

Cavity No.

Single or multi

System Of Runner

Hot runner,Cold runner,Pin-point gate,Submarine gate, etc

Ejector Type

Ejector pin,Ejector plate,Hydro-cylinder,etc

Term Of Mould Production

25 days- 55 days

Guaranteed Number Of Cycles

500,000-1,000,000 shots

Mould Design Software

Ug, Proe, Solidworks, AutoCAD, Moldflow, etc

Mould Produce Process

Product Design: Customer send the product drawing to us directly or we make the product design according to the sample then send to customer for confirmation

Our Factory

Established in 1996,Topwell has 21 years for plastic mold making and plastic injection, we have 125 sets injection machines from 90 to 1000 ton, we built R&D team and we can serve Industrial Design, Mechanical Design and Electronic Design.

We are professional OEM/ODM of plastic tooling and injection molding,secondary process and product assembly in China. Topwell has developed and manufactured a wide range of tools and plastic products for home products, Automotive, Telecommunications, OA, Medical and Electronic industry.

Our main products include R&D Electronic Product Design, Injection mould, IML/IMD Moulding Parts, Silicon Mould, Metal Parts, Complete Final Product Assemble, Rapid Prototype Parts, Precision CNC Parts.

And looking at the catalog, you can know ODM Mechanical Design Electric plastic mould is belonging to R&D Electronic Product Design, and in this catalog you can search R&D Electronic Product Design,Customized Electronic Project Design, OEM Plastic Parts Customized Design,Custom Industrial Design. If you are interested in this catalog you can touch these underline to see more.

Topwell is proud of being an innovative company in mold design and efficient manufacturing processes. We are committe to long term development and looking forwards to establishing a strong business partnership with your company.

The management team at Topwell welcome you to here and looks forwards to working with your company for many years.

Supplier Advantage

1.Mold design is subject to customer's requirement.

Packing and Shipping

1.For mold: After assemble and clear mold ,we paint anti-rust for or grease on mold ,then cover it with thin film and place it into a stable wooden box.

FAQ

1. Do you do OEM & ODM products?

Yes, we are specialized on OEM & ODM products.

2. Are you factory?

3. I have no drawing, how I should do to start the new project ?

You can supply a sample, we will help to finish the 3D drawing design.

4. What is your shipment way?

Molds for meeting instrument with assembly injection factory

Mould Design: We'll to make mould design after the product drawing approval,then send the mould design to customer for confirmation

Mould Manufacture: We will start to make mould after mould design approval,the process include prepare material,rough cut,finish machining,assembly etc

Mould Test: We'll test the mould after finishing mould assembly,then we'll send samples and video of test to customer for checking

Final Process: We'll make the polishing for mould after the sample approval and make grain,nitridation or chroming if customer required

Mould Packing: We'll stard to pack the mould with wooden case after the final sample approval,then the mould will be sent to port and waiting for shipping

2.Injection molding machine specification of certain plastic,etc.Our products include a variety of vacuum cleaners,and plastic components.These products are widely available to world-class large companies.We have won a high reputation among clients.Our company provides processing or researching and manufacturing services.We are very interested in the development of new products to meet market demands.

3.specifications about flow,material, radian and so on,we can fit in all you want.

2.For plastic products: The first thing is to wrap each part up with semi-transparent thin foam and put it into plastic bag, the second step is place them into cartons with thin sponge plates to prevent scratches.

Related Keywords