Printed circuit board assembly

Your message must be between 20 to 2000 characters

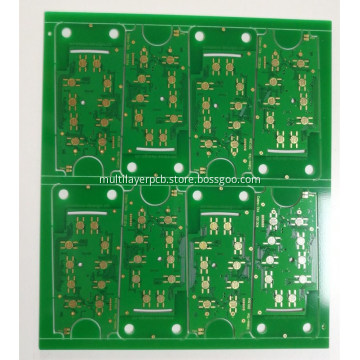

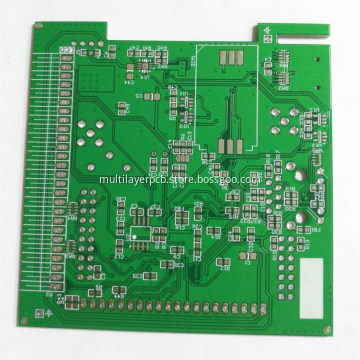

Contact NowPCB assembly technology is usually divided into two types: one is dual in-line package technology(DIP), and the other is in surface-mount technology (SMT).

The bare board is populated with electronic components to form a functional. In through-hole technology, the component leads are inserted in holes surrounded by conductive pads; the holes keep the components in place.

In surface-mount technology (SMT), the component is placed on the PCB so that the pins line up with the conductive pads or lands on the surfaces of the PCB; solder paste, which was previously applied to the pads, holds the components in place temporarily; if surface-mount components are applied to both sides of the board, the bottom-side components are glued to the board. In both through hole and surface mount, the components are then soldered; once cooled and solidified, the solder holds the components in place permanently and electrically connects them to the board.

Related Keywords