medical infrared thermometer electronic assembly

- Payment Type:

- T/T

- Incoterm:

- FOB

- Transportation:

- Air

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB |

| Transportation: | Air |

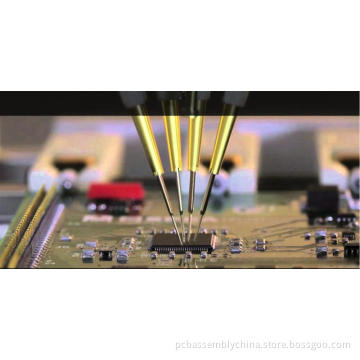

Instrumentation medical devices infrared thermometer pcba assembly electronics oem contract manufacturing services OEM CEM EMS experience company-China Shenzhen Topscom

Infrared thermometer device Electronic OEM EMS CEM Contract Manufacturing PCb assembly service

An infrared thermometer is a thermometer which infers temperature from a portion of the thermal radiation sometimes called blackbody radiation emitted by the object being measured. They are sometimes called laser thermometers if a laser is used to help aim the thermometer, or non-contact thermometers or temperature guns, to describe the device's ability to measure temperature from a distance. By knowing the amount of infrared energy emitted by the object and its emissivity, the object's temperature can often be determined. Infrared thermometers are a subset of devices known as "thermal radiation thermometers".

Sometimes, especially near ambient temperatures, readings may be subject to error due to the reflection of radiation from a hotter body-even the person holding the instrument[citation needed]-rather than radiated by the object being measured, and to an incorrect assumed emissivity.

The design essentially consists of a lens to focus the infrared thermal radiation on to a detector, which converts the radiant power to an electrical signal that can be displayed in units of temperature after being compensated for ambient temperature. This permits temperature measurement from a distance without contact with the object to be measured. A non-contact infrared thermometer is useful for measuring temperature under circumstances where thermocouples or other probe-type sensors cannot be used or do not produce accurate data for a variety of reasons.

The most common infrared thermometers are the:

Spot Infrared Thermometer or Infrared Pyrometer, which measures the temperature at a spot on a surface (actually a relatively small area determined by the D:S ratio). These usually project a visible red dot onto the center of the area being measured; this identifies the spot being measured but plays no part in the measurement. The actual angular area being measured varies between instruments, and is not restricted to the visible spot.

Related equipment, although not strictly thermometers, includes:

Infrared Scanning Systems scan a larger area, typically by using what is essentially a spot thermometer pointed at a rotating mirror. These devices are widely used in manufacturing involving conveyors or "web" processes, such as large sheets of glass or metal exiting an oven, fabric and paper, or continuous piles of material along a conveyor belt.

Infrared Thermal Imaging Cameras or Infrared Cameras are essentially infrared radiation thermometers that measure the temperature at many points over a relatively large area to generate a two-dimensional image, called a thermogram, with each pixel representing a temperature. This technology is more processor- and software-intensive than spot or scanning thermometers, and is used for monitoring large areas. Typical applications include perimeter monitoring used by military or security personnel, inspection / process quality monitoring of manufacturing processes, and equipment or enclosed space hot or cold spot monitoring for safety and efficiency maintenance purposes.

A photographic camera using infrared film and suitable lens, etc., is also called an infrared camera. This only captures the short wave and is not sensitive to the thermal radiation from room temperature objects.

Related Keywords