Turnkey Pcbs Assembly Oem Manufactuirng Service

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Delivery Time:

- 90 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

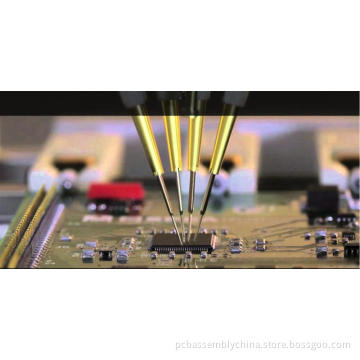

Turnkey Electronic Circuit Boards Pcb assembly Services,Contract Electronic OEM Manufacturing.

Topscom offers turn-key PCB assembly services in prototype or low production and mass prodution volumes. We handle the whole process including: ordering all the components, PCB manufacturing, PCB assembly, testing and final shipment. We are capable of assembling BGA, Micro-BGA, QFN and other leadless package parts.

SMT and Through-Hole Assembly Fine Pitch Component InsertionLead free Assembly BGA and QFN Assembly

One-stop PCB Assembly BGA X-Ray Inspection

Prototype PCB Assembly Automated Optical Inspection

PCB Assembly in low volumes PCB testing for functionality

Topscom was founded in 1995 and has since established itself as a reliable full turn-key electronic contract manufacturer (ECM) and one stop PCB manufacturing and assembly company. As a provider of one stop PCB assembly services, our firm provides expert consulting in Design for Manufacturing (DFM). Our headquarters is based shenzhen china, and our sales office is located in San Jose California. We run production plants in Shenzhen, China. This allows Topscom to provide low cost PCB manufacturing, parts procurement, and PCB assembly using local supply chains/

Our circuits assembly services make use of our own PCB manufacturing facility, electronic components procurement team and PCB assembly house in Shenzhen, China. As an IPC member, Topscom has certified all of its facilities to ISO9001, and they also are in compliance with IPC-A-600 & IPC-A-610.

Microelectromechanical systems (MEMS, also written as micro-electro-mechanical, MicroElectroMechanical or microelectronic and microelectromechanical systems and the related micromechatronics) is the technology of microscopic devices, particularly those with moving parts. It merges at the nano-scale into nanoelectromechanical systems (NEMS) and nanotechnology. MEMS are also referred to as micromachines in Japan, or micro systems technology (MST) in Europe.

MEMS are separate and distinct from the hypothetical vision of molecular nanotechnology or molecular electronics. MEMS are made up of components between 1 and 100 micrometres in size (i.e. 0.001 to 0.1 mm), and MEMS devices generally range in size from 20 micrometres to a millimetre (i.e. 0.02 to 1.0 mm). They usually consist of a central unit that processes data (the microprocessor) and several components that interact with the surroundings such as microsensors.At these size scales, the standard constructs of classical physics are not always useful. Because of the large surface area to volume ratio of MEMS, surface effects such as electrostatics and wetting dominate over volume effects such as inertia or thermal mass.

The potential of very small machines was appreciated before the technology existed that could make them (see, for example, Richard Feynman's famous 1959 lecture There's Plenty of Room at the Bottom). MEMS became practical once they could be fabricated using modified semiconductor device fabrication technologies, normally used to make electronics. These include molding and plating, wet etching (KOH, TMAH) and dry etching (RIE and DRIE), electro discharge machining (EDM), and other technologies capable of manufacturing small devices. An early example of a MEMS device is the resonistor – an electromechanical monolithic resonator.

Related Keywords