pcb desing manufacturing and assembly

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

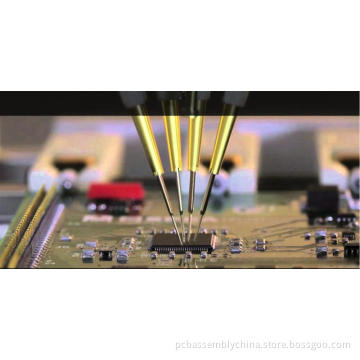

china pcb boards pcba assembly contract manufacturing for finished electronics products

Topscom dedicated to lean manufacturing techniques in all of our operations, including box build assembly and turnkey assembly. We have numerous box build assembly working experiences dedicated to our customers' completed products, ensuring that we continually maximize efficiency and improve our processes through skillful workers and strong engineering capabilities.

We established completed green supply chain which ensure us can get the qualified materials and components of the plastic, metal, cable, rubber, membrane keypad, LCD and other parts very quickly.

Our Box Build Assembly Services

1) Global and domestic supply chain for all of your custom manufactured components and materials;

2) Incoming inspection to ensure all components are to specification;

3) Individual component assembly;

4) Sub-assembly testing;

5) Cable assembly;

6) Complete cabinet assembly and testing;

7) Skillful workers and strong engineering capabilities;

8) Many years experiences in the box build assembly industry;

Type of Assembly SMT, Thru-hole,COB, BGA

SMT Position accuracy:20 um

Components size:0.4×0.2mm(01005) _130×79mm,Flip-CHIP,QFP,BGA,POP

Max. component height::25mm

Max. PCB size:680×500mm

Min. PCB size:no limited

PCB thickness:0.3 to 7mm

Wave Solder Max. PCB width:450mm

Min. PCB width: no limited

Component height:Top 120mm/Bot 15mm

Sweat-Solder Metal type :part, whole, inlay, sidestep

Metal material:Copper , Aluminum

Surface Finish:plating Au, plating sliver , plating Sn

Air bladder rate:less than20%

Supporting: Software burning and Function Testing

Testing X-RAY Inspection & AOI Test, ICT,flying probe testing, program burn-in,function test,temperature cycling

Lead Time 12days-15days

File Fomat Bill of Materials,Gerber Files, Pick-N-Place File (XYRS),PCB,Altium, EDA etc

our Pre-Sale service Support:

1) Communicate with customers carefully for all requirements and specifications;

2) Give our design improvement suggestions to customers;

3) Provide several different solutions for our customers to comparision;

4) Design the engineering artwork for customer's approval;

5) Provide relevant materials datasheets and certificates;

After-Sales Service

A good after-sales service can give our customers a very good purchasing experience. It can make our customers feel satisfactory to us. A good after-sales service also can found problems and make the solution to them in time. LUPHI is a responsible factory. For each customer, no matter they do big business with us or small business with us, we all will provide good service to them. This is our operation mission.

Related Keywords

Related Keywords