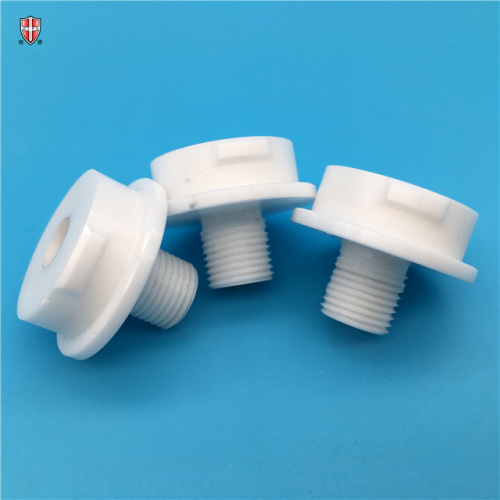

precision customized zirconia ceramic threaded components

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

precision customized zirconia ceramic threaded components

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Special ceramics are the main raw materials used in these ceramics developed with the rapid development of modern electrical appliances, radio, aviation, atomic energy, metallurgy, machinery, chemical and other industries and electronic computers, space technology, new energy development and other cutting-edge science and technology. It is clay, feldspar, quartz, and some blanks also use some clay or feldspar. However, more pure oxides and raw materials with special properties are used. The manufacturing process and performance requirements are also different. , Using silicon powder as raw material, adding 30% mass fraction of porogen (benzoic acid) spherical particles, reactive sintering prepared a porosity of 55%, low density porous silicon nitride ceramics with spherical macropores studied silicon powder particles The influence of the diameter on the dielectric properties of reactive sintered porous silicon nitride ceramics. The hardness of silicon nitride is high, Hv = 18GPa ~ 21? Gpa, HRA = 91 ~ 93, second only to diamond, cubic BN, B4C, etc. Hard material, low friction coefficient (0.1), self-lubricating, similar to lubricated metal surface (0.1--0. 2)

Silicon nitride is a covalent compound, so the atoms are combined with strong covalent bonds, so it has a high hardness and melting point

Can be used as raw material for high temperature ceramics

The energy dissipation ability of any material can be easily evaluated by the hardness and elastic modulus of the material. At the same time, for materials with known energy dissipation ability, the elastic modulus can be estimated from the hardness value. Therefore, in the selection of materials or reliable In terms of performance evaluation, many material properties, such as brittleness, local energy dissipation ability, elastic recovery ability, resistance characteristics, guided wave rate, etc., can be simply estimated and compared by hardness and elastic modulus. This is for material design and structural design. And material performance prediction are of great significance

The ceramic material is a combination of polycrystals. The junction between the same-component grains with different crystal directions is called the grain boundary, and the junction between the good-component grains is called the phase boundary. Both are important for the microstructure. The research object studies the material at the grain boundary [structure characteristics, called the grain boundary structure.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

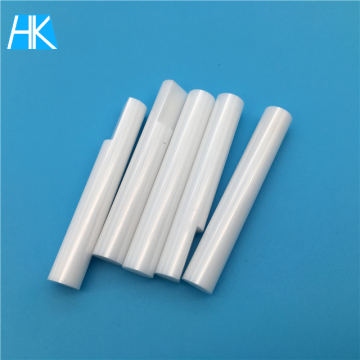

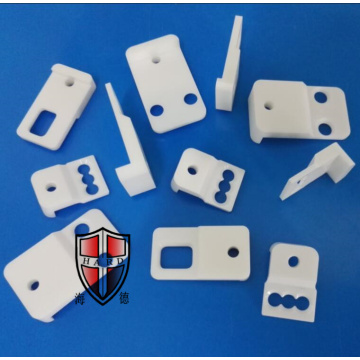

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords