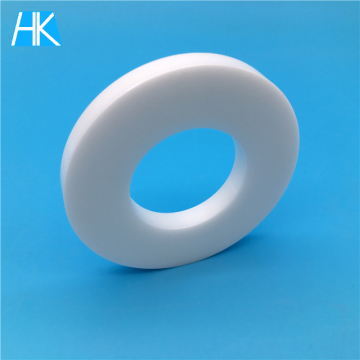

wearable shining zirconia ZrO2 ceramic ring loop link

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

wearable shining zirconia ZrO2 ceramic ring loop link

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

In general, the higher the dispersion of the material, the higher the surface energy. Therefore, it has a strong force to promote migration and diffusion, which is conducive to sintering. At the same time, in the process of full pulverization, the defects inside and on the surface of the particles increase, effectively improving The mobility of the particles. Whether in solid or liquid sintering, fine particles increase the sintering rate by increasing the driving force of sintering, shortening the atomic diffusion distance and increasing the solubility of the particles in the liquid phase. When the agglomeration of the original powder particles is serious and the compact packing property is poor, and the pressure gradient is distributed when the green body is pressed and the admixture is not mixed with the powder, the density and composition of the various parts of the green body are uneven. The green body thus produces uneven densification upon sintering. Usually, the addition of an admixture will cause the grain boundary movement of the material during sintering to suppress grain growth, but in some cases, the result is just the opposite. For example, in solid phase sintering, a small amount of additives (also known as sintering aids) can form a solid solution with the main crystalline phase to promote the increase of defects; in liquid phase sintering, additives can change the properties of the liquid phase (such as viscosity, composition, etc.) To promote the role of sintering.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords