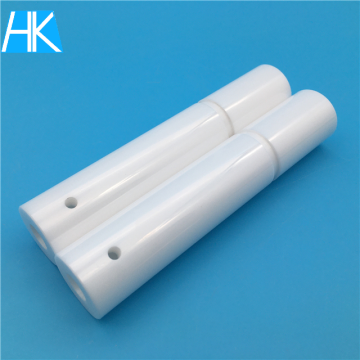

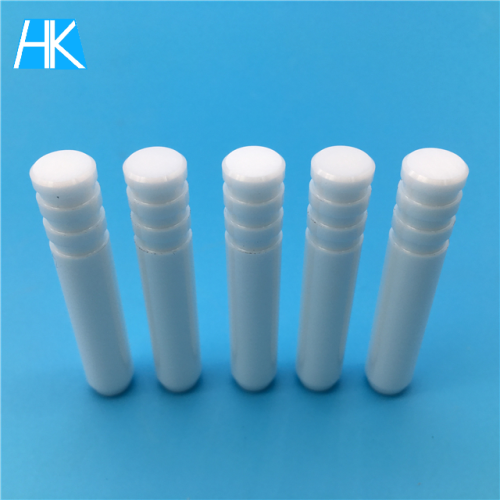

anti-corrosion zirconia ceramic seramik piston plunger shaft

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

anti-corrosion zirconia ceramic seramik piston plunger shaft

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Zirconia ceramics have also appeared in shape memory alloys such as Ti-Ni, Ti-Ni-Fe, Ti-Ni-Nb since the 1970s, and they have been increasingly used in engineering.

There are hundreds of types of zirconia developed in the world, and there are 20-30 types of the most famous alloys, such as Ti-6Al-4V, Ti-5Al-2.5Sn, Ti-2Al-2.5Zr, Ti-32Mo, Ti- Mo-Ni, Ti-Pd, SP-700, Ti-6242, Ti-10-5-3, Ti-1023, BT9, BT20, IMI829, IMI834, etc. According to relevant statistics, the amount of zirconium used in my country's chemical industry reached 25,000 tons in 2012, a decrease from 2011. This is the first time that my country's chemical titanium market has experienced negative growth since 2009. In recent years, the chemical industry has been the largest user of titanium processing materials, and its consumption has remained at more than 50% of the total consumption of titanium materials, and it accounted for as high as 55% in 2011. However, as the economy has fallen into a downturn, the chemical industry will not only significantly reduce new projects, but will also face adjustments in the industrial structure. The new production capacity of some products will be controlled, and outdated production capacity will be phased out. Affected by this, the shrinkage of the amount of titanium processed materials has also become a matter of course. Before that, some insiders predicted that the amount of titanium used in the chemical industry would reach its peak between 2013 and 2015. Judging from the current market performance, the overall economic weakness in 2012 may advance the decline of chemical titanium. Titanium alloys are alloys based on titanium added with other elements. Titanium has two isomorphs: close-packed hexagonal α titanium below 882°C, and body-centered cubic β titanium above 882°C.

Zirconium oxide alloy elements can be divided into three categories according to their influence on the phase transition temperature:

①The elements that stabilize the α phase and increase the phase transition temperature are α stabilizing elements, such as aluminum, carbon, oxygen, and nitrogen. Among them, aluminum is the main alloy element of titanium alloy, which has obvious effects on improving the alloy's normal temperature and high temperature strength, reducing specific gravity, and increasing elastic modulus.

②The element that stabilizes the β phase and reduces the phase transition temperature is the β-stabilizing element, which can be divided into two types: isomorphic and eutectoid. The former includes molybdenum, niobium, vanadium, etc.; the latter includes chromium, manganese, copper, iron, silicon and so on.

③ The elements that have little effect on the phase transition temperature are neutral elements, such as zirconium and tin.

Oxygen, nitrogen, carbon and hydrogen are the main impurities in titanium alloys. Oxygen and nitrogen have greater solubility in the α phase, which has a significant strengthening effect on the titanium alloy, but it reduces the plasticity. It is usually stipulated that the oxygen and nitrogen content in titanium is 0.15-0.2% and 0.04-0.05% or less, respectively. The solubility of hydrogen in the α phase is very small, and too much hydrogen dissolved in the titanium alloy will produce hydrides, which will make the alloy brittle. Generally, the hydrogen content in titanium alloys is controlled below 0.015%. The dissolution of hydrogen in titanium is reversible and can be removed by vacuum annealing.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords