eco-friendly rust resistant zirconia ceramic blade razor

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

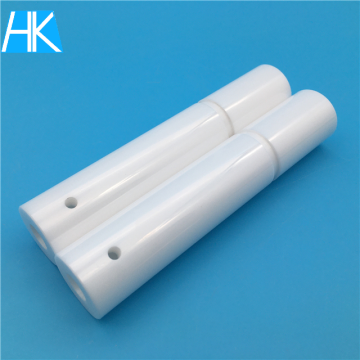

eco-friendly rust resistant zirconia ceramic blade razor

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

The zirconia ceramic blade is made of high-purity ultra-fine zirconia and is manufactured by spray granulation, isostatic pressing and precision machining. It has high hardness, strong corrosion resistance, good chemical stability and high wear resistance. Sex and other characteristics, the appearance is beautiful and exquisite, the cutting edge is very sharp, it is a knife that is not worn or corroded in the true sense. The zirconia ceramic blades are all hand-polished, and each face is evenly curved inward, which ensures the strength of the ceramic knives to a large extent, while ensuring smoothness during cutting. The hand-polished blade and knife face are uniform and the finish is extremely high and easy to clean.

Preparation of zirconia ceramic blades

1. Mixing ingredients: ball milling → vibrating grinding → ball milling → adding glue → ball milling;

2. Pressing the blank: The dry powder pressing process of the ceramic blade has high requirements on the powder morphology, the surface charge state of the powder and the granulation of the mixed powder, so the pressing process is difficult;

3. Blank body discharging: The degumming process of the ceramic blade is similar to the production process of the cemented carbide tool;

4, GPS + HIP processing: sintering process using atmosphere protection sintering (GPS) + hot isostatic pressing (HIP) processing technology;

5, blade sharpening: the quality of the sharpening of the ceramic blade has a great impact on the performance of the tool;

6, the installation handle: there are 3 large material handles, plastic handles (ABS), wooden handles, ceramic handles.

7. Test knives: For the ceramic blades produced in different batches and at different times, in addition to monitoring their performance indicators, test knives should be carried out before leaving the factory to check the cutting performance of the blades. The test knives are generally completed on the machine tool of the factory;

8, packaging inspection: inspection of damaged, defective products, defective products, qualified, packaging.

The zirconia ceramic blade fully reflects the green environmental protection concept of the new century and new materials, environmentally friendly new fashion, and feels new life. It is a high-quality life for human beings to pursue environmental protection and health. The light and beautiful, fine and transparent appearance adds a noble and modern phase. The fusion of zirconia ceramic blades has become a trend in place of metal knives.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords