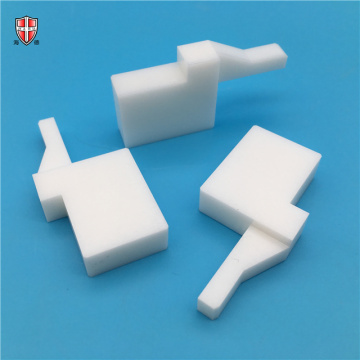

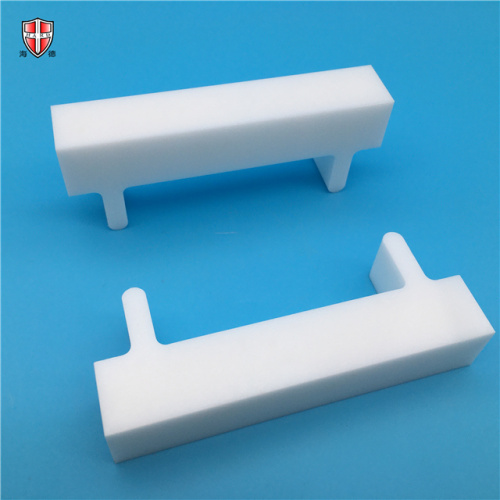

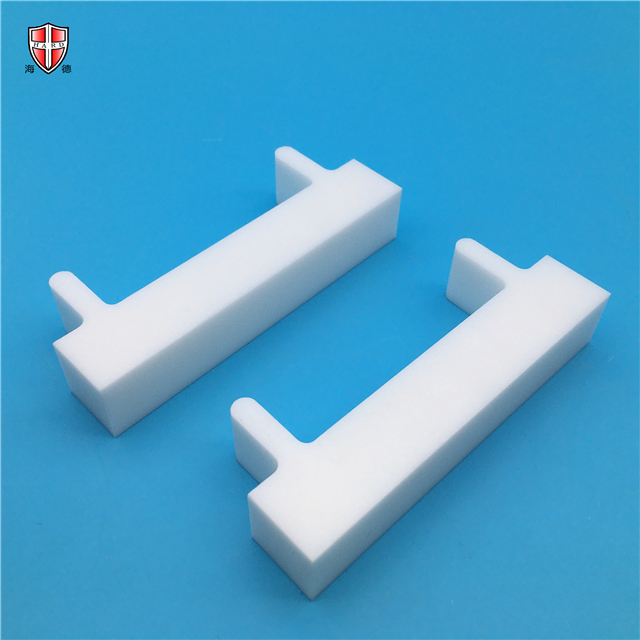

isostastic sintered zirconia ceramic step block support

-

$5.001-99 Piece/Pieces

-

$3.00100-999 Piece/Pieces

-

$1.001000-9999 Piece/Pieces

-

$0.50≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 100,000pcs/month |

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

isostastic sintered zirconia ceramic step block support

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Zirconia ceramics are used for machining planes, steps, grooves, forming surfaces and cutting workpieces on milling machines.

There are many commonly used types of milling cutters according to their purposes:

①Cylindrical milling cutter: used for processing planes on horizontal milling Ceramic Plunger machines. The cutter teeth are distributed on the circumference of the milling cutter. According to the tooth shape, they are divided into straight teeth and spiral teeth. According to the number of teeth, there are two types: coarse teeth and fine teeth. The helical coarse-tooth milling cutter has few teeth, high tooth strength and large chip holding space, which is suitable for rough machining; fine-tooth milling cutter is suitable for fine machining.

②Face milling cutter: used for vertical milling machine, face milling machine or gantry milling machine, upper processing plane, there are cutter teeth on the end face and circumference, and there are also coarse and fine teeth. Its structure has three types: integral type, insert type and indexable type.

③End milling cutter: used for processing Alumina Zirconia grooves and step surfaces, etc. The cutter teeth are on the circumference and end surface, and cannot be fed along the axial direction when working. When the end mill has end teeth passing through the center, it can be fed axially (usually double-edged end mills are also called "keyway milling cutters" that can feed axially).

④Three-sided face milling cutter: used to process various grooves and stepped surfaces, with teeth on both sides and circumference.

⑤Angle milling cutter: It is used for milling grooves at a certain angle. There are two types of single-angle and double-angle cutters.

⑥ Saw blade milling cutter: used to process deep grooves and cut off the workpiece, with more teeth on the circumference. In order to reduce friction during milling, there are 15'~1° secondary deflection angles on both sides of the Industrial Ceramic cutter teeth. In addition, there are keyway milling cutters, dovetail milling cutters, T-slot milling cutters and various forming milling cutters.

The structure of the milling cutter is divided into 4 types:

①Integral type: The cutter body and the cutter teeth are made into one body.

②Integral welding tooth type: The cutter teeth are made of cemented carbide or other wear-resistant tool materials and brazed on the cutter body.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords