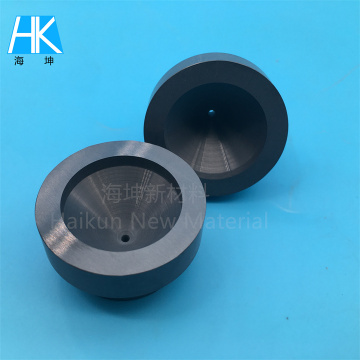

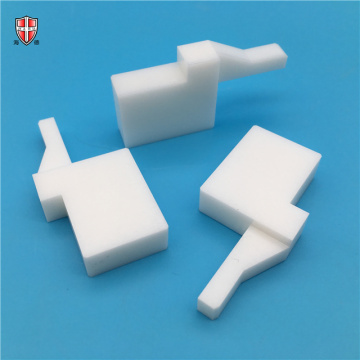

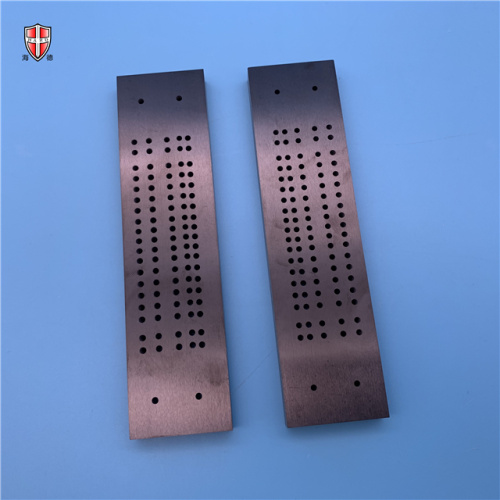

insulating black zirconia ceramic electronic accessories

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

insulating black zirconia ceramic electronic accessories

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Zirconia polyethylene is an alkane inert polymer with good chemical stability. It is resistant to acid, alkali, and salt solutions at room temperature, but it is not resistant to strong oxidants such as fuming sulfuric acid, concentrated nitric acid and chromic acid. Polyethylene is insoluble in general solvents below 60°C, but it will swell or crack when it comes in contact with aliphatic hydrocarbons, aromatic hydrocarbons, halogenated hydrocarbons, etc. for a long time. When the temperature exceeds 60℃, it can be dissolved in a small amount of toluene, amyl acetate, trichloroethylene, turpentine, White Machinable Glass Ceramic Parts mineral oil and paraffin; the temperature is above 100℃, it can be dissolved in tetralin. As the polyethylene molecule contains a small amount of double bonds and ether bonds, sun and rain will cause aging, and antioxidants and light stabilizers need to be added to improve it. Because LDPE and HDPE have good fluidity, low processing temperature, moderate viscosity, and low decomposition temperature, they will not decompose at a high temperature of 300°C in an inert gas, so they are plastics with good processing properties. However, the viscosity of LLDPE is slightly higher, and the motor power needs to be increased by 20% to 30%; melt fracture is prone to occur, and the gap between the die and the processing aid needs to be increased; the processing temperature is slightly higher, up to 200-215°C. Polyethylene has low water absorption and does not require drying before processing.

Polyethylene melt is a non-Newtonian fluid, and its viscosity fluctuates slightly with temperature, while the increase in shear rate decreases quickly and shows a linear relationship, of which LLDPE decreases the slowest.

Polyethylene products are easy to crystallize during the cooling process, so pay attention to the mold temperature during the processing. In order to control the crystallinity of the product, make it have different properties. The molding shrinkage rate of polyethylene is large, which must be considered when designing the mold.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords