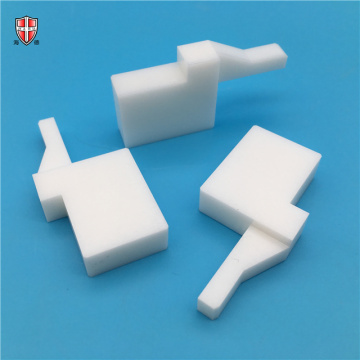

low thermal zirconia ceramic structural components

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

low thermal zirconia ceramic structural components

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Dry press molding uses pressure to compress ceramic powder into a shaped body. The essence is that under the action of external force, the powder particles are close to each other in the mold, and are firmly combined by internal friction to maintain a certain shape. The main defect in dry pressed greens is lamellar cracking due to internal friction between the powder and friction between the powder and the mold wall, resulting in pressure loss inside the blank. The advantages of dry pressing are that the size of the blank is accurate, the operation is simple, and the mechanization operation is facilitated; the dry pressed green body has less moisture and binder content, and the drying and firing shrinkage are small. It is mainly used to form products of simple shape with a small aspect ratio. Increased production costs due to mold wear are a disadvantage of dry pressing. Isostatic pressing is a special molding method developed on the basis of conventional dry pressing. It utilizes fluid transfer pressure to apply pressure uniformly to the powder in the elastomeric mold from all directions. Due to the consistency of the internal pressure of the fluid, the pressure of the powder in all directions is the same, so that the difference in density within the body can be avoided.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords