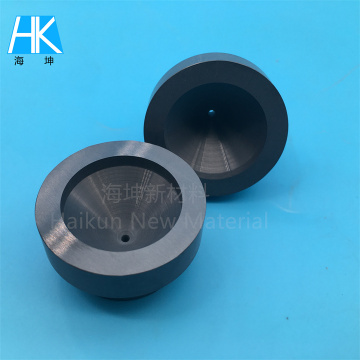

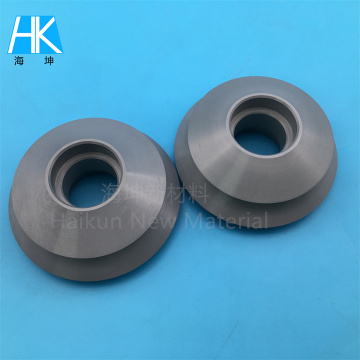

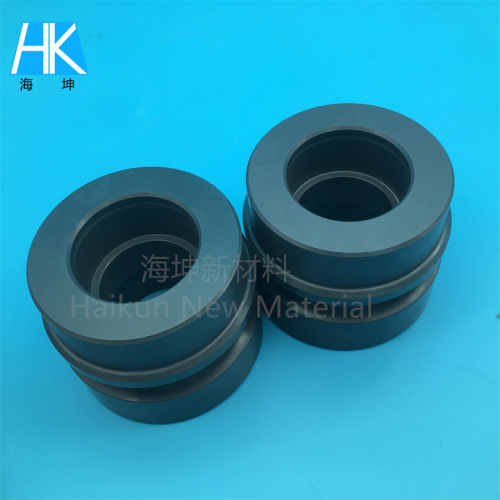

Silicon Nitride (Si3n4) Ceramic Roller Guide Pulley Parts

-

$8.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Dongguan, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000pcs/month |

| Supply Ability: | 10000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,Express Delivery,DDP |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Dongguan,Guangzhou |

Silicon Nitride (Si3n4) Ceramic Roller Guide Pulley Parts

Silicon Nitride (Si3N4) ceramic roller guide pulleys are high-performance components often used in industrial applications where high precision, durability, and resistance to wear are critical. These pulleys are particularly favored in systems requiring continuous operation under harsh conditions, such as in the automotive industry, aerospace, and manufacturing equipment. Here's a breakdown of how they are used and their key features:

Key Features of Silicon Nitride Ceramic Roller Guide Pulleys

1. **High Thermal Stability**: Silicon Nitride has a high melting point and is thermally stable over a wide range of temperatures, making it ideal for environments where thermal fluctuations are common.

2. **Low Coefficient of Friction**: This material has one of the lowest coefficients of friction among ceramics, which enhances efficiency and reduces energy loss during operation.

3. **Resistance to Wear and Corrosion**: Silicon Nitride is highly resistant to wear and corrosion, offering longer service life and reduced maintenance costs.

4. **High Strength and Rigidity**: It can withstand high loads and stresses without deformation, ensuring reliable performance under heavy duty conditions.

5. **Lightweight**: Compared to metals with similar strength properties, Silicon Nitride is lighter, which can reduce overall system weight and improve performance.

Applications:

-**Automotive Industry**: Used in engine components, transmission parts, and high-performance gears where lightweight, high-strength, and low-friction materials are essential.

- **Aerospace**: In aircraft engines, propellers, and other components that require lightweight, high-temperature resistance, and durability.

- **Manufacturing Equipment**: In conveyor systems, precision machinery, and robotics where precise movement and minimal wear are required.

- **Electronics**: In semiconductor manufacturing equipment due to its thermal stability and resistance to contamination.

Manufacturing Process:

The production of Silicon Nitride ceramic roller guide pulleys typically involves several steps:

- **Powder Preparation**: High-purity silicon and nitrogen are combined to form a ceramic powder.

- **Compaction**: The powder is compacted into the desired shape using techniques like hot isostatic pressing (HIP).

- **Sintering**: The compacted part is then sintered at high temperatures to form a dense ceramic body.

- **Finishing**: Surface treatments may be applied to enhance specific properties such as surface hardness or lubricity.

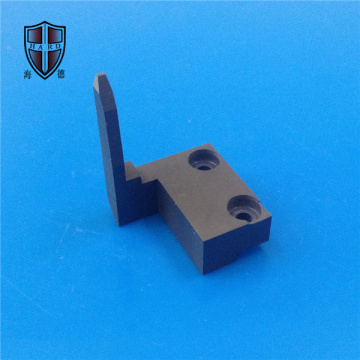

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Parts widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry!

What'sapp/Wechat: +86-13823242056

Related Keywords