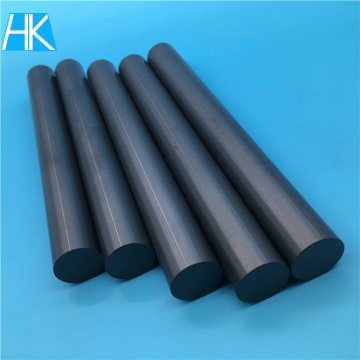

Insulation Si3n4 Ceramic Welding Rod Pin Bar

-

$6.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Dongguan, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100000pcs |

| Supply Ability: | 100000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Dongguan,Guangzhou |

Silicon Nitride Welding Rod Pins

Silicon Nitride are commonly used as ceramic materials in the metallurgical industry because of their uniform properties at high temperatures.Silicon Nitride Ceramic Welding Rod Pins offer excellent resistance to thermal shock due to its microstructure.The creep and oxidation resistance of Silicon Nitride Ceramic is also excellent, and its low thermal conductivity and high wear resistance make it an excellent material that can withstand the conditions of most industrial applications.

There are 5 different methods to produce Silicon Nitride Welding Rods including SRBSN, GPSN, HPSN, HIP-SN and RBSN, making the application and working material different slightly. GPSN is most commonly used to produce silicon nitride parts components.

Applications for Silicon Nitride Welding Rod Pins

1. Industrial machinery: for the repair and manufacture of components that operate at high temperatures and under abrasive conditions, such as machine parts, moulds and dies.

2. Aerospace: used in the aerospace industry to weld and repair high-temperature components and structures, benefiting from their thermal stability and strength.

3. Automotive industry: for the manufacture and repair of automotive components requiring high wear resistance and durability, including engine components and exhaust systems.

4. Chemical processing: welding equipment and components for handling aggressive chemicals, taking advantage of silicon nitride's chemical inertness and corrosion resistance. 5. electronics: used in semiconductor manufacturing.

5. Electronics: for the production and repair of semiconductor manufacturing equipment where high precision, resistance to wear and thermal shock are essential.

6. Energy Industry: for welding and repair of power plant components, especially in high temperature and high pressure environments, such as gas turbines and boilers.

7. Tools and cutting instruments: for the manufacture and repair of cutting tools and other precision instruments, benefiting from their hardness and wear resistance.

8. Medical equipment: for the manufacture and repair of medical equipment and instruments, especially those requiring high precision, biocompatibility, wear and corrosion resistance.

9. Defence and military: for the manufacture and repair of military equipment and vehicles, where durability and performance are essential under extreme conditions.

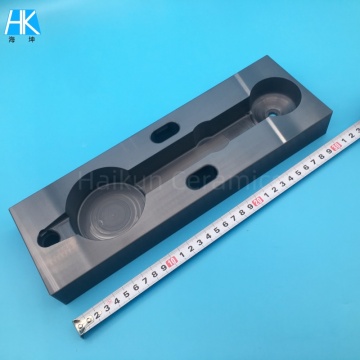

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords