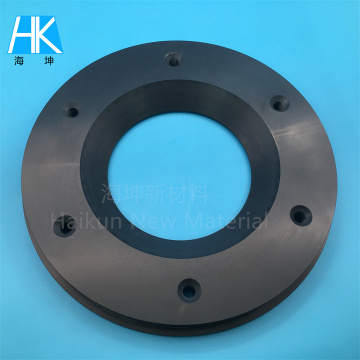

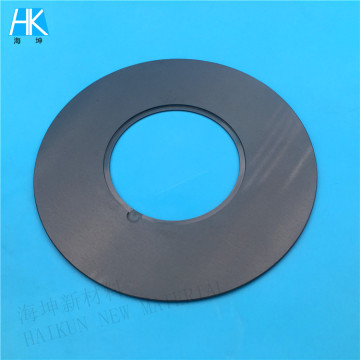

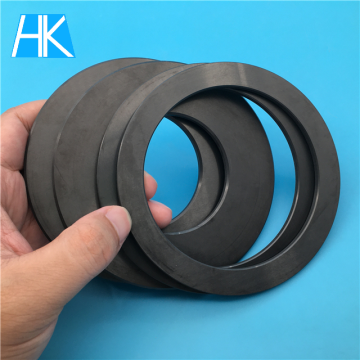

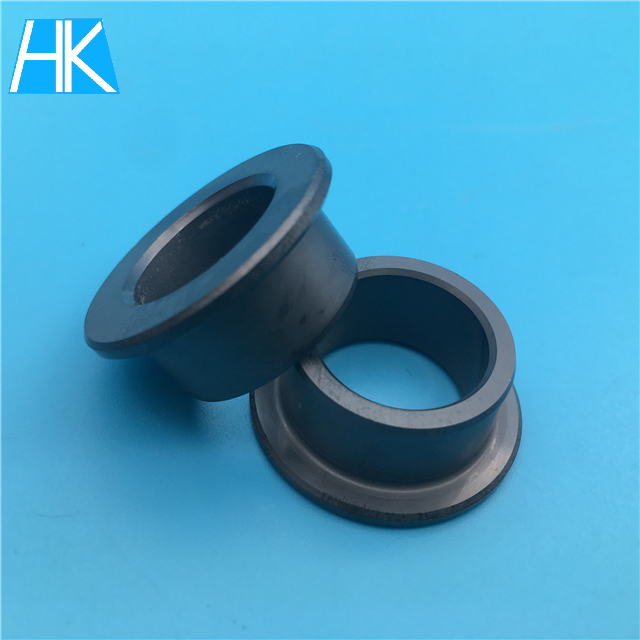

anti-rust Sintering Si3N4 Ceramic Bearing Washer Sleeve Ring

-

$0.5010-99 Piece/Pieces

-

$0.30100-999 Piece/Pieces

-

$0.201000-9999 Piece/Pieces

-

$0.10≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

anti-rust Sintering Si3N4 Ceramic Bearing Washer Sleeve Ring

Reputation depends on quality, quality comes from Hard!

Silicon nitride ceramic:

The function of silicon nitride ceramics is to lead the electrodes to the LED chip to complete the connection of the inner and outer leads of the product.Silicon nitride ceramic ring is one of the key components in the LED pressure welding process. There are two types of LED pressure welding processes: gold wire ball welding and aluminum wire pressure welding. The process of aluminum wire pressure welding is to press the first point on the LED chip electrode, then pull the aluminum wire to the top of the corresponding bracket, press the second point and then tear the aluminum wire. The gold wire ball bonding process burns a ball before pressing the first point, and the rest of the process is similar. Pressure welding is a key link in LED packaging technology, and the process is mainly to monitor the shape of the pressure-bonded gold wire (aluminum wire) arch wire, the shape of the solder joint, and the tension.

There are three main types of LED packaging: dispensing, potting, and molding. Basically, the difficulty of process control is air bubbles, lack of material and black spots. The design is mainly about the selection of materials, and the selection of epoxy and brackets with good combination. (General LEDs cannot pass the air tightness test).

LED Dispensing TOP-LED and Side-LED are suitable for dispensing packaging. Manual dispensing and encapsulation requires a high level of operation (especially for white LEDs), and the main difficulty is the control of the amount of glue dispensed, because the epoxy will thicken during use. The dispensing of white LEDs also has the problem of chromatic aberration caused by the precipitation of phosphor powder. LED potting packaging Lamp-LED packaging is in the form of potting. The process of potting is to first inject liquid epoxy into the LED molding cavity, then insert the pressure-welded LED bracket, put it in an oven to cure the epoxy, and then remove the LED from the cavity to form.

LED molding package Put the pressure-welded LED bracket into the mold, close the upper and lower molds with a hydraulic press and vacuumize, put the solid epoxy into the entrance of the injection channel, and press the hydraulic ejector into the mold rubber channel for heating. The epoxy enters each LED molding tank along the glue channel and cures.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords