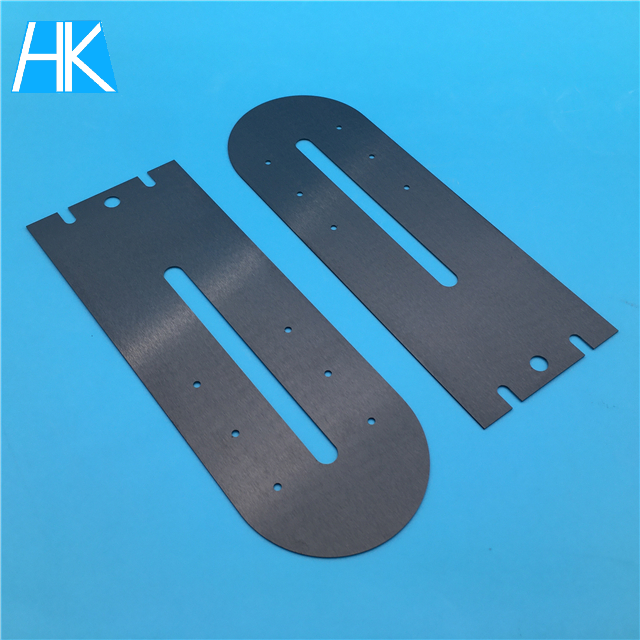

laser cutting silicon nitride ceramic substrate sheet plate

-

$0.5010-99 Piece/Pieces

-

$0.30100-999 Piece/Pieces

-

$0.201000-9999 Piece/Pieces

-

$0.10≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

laser cutting silicon nitride ceramic substrate sheet plate

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramics:

The development of silicon nitride OLED materials is the basis for the vigorous development of the OLED industry. The earliest OLED light-emitting materials are fluorescent materials, but the upper limit of the theoretical quantum efficiency of fluorescent materials can only reach 25% due to spin inhibition. In 1998, Ma and Forrest and Thompson successively reported the application of phosphorescent materials in OLED materials, which paved the way for breaking the law of spin statistics and utilizing 100% of the energy of all excitons. However, phosphorescent materials also have certain problems. Due to the inclusion of precious metals, the price is high and the stability of blue light materials has been stagnant for a long time.

In 2009, Professor Adachi from Kyushu University in Japan introduced thermally activated delayed fluorescence (TADF) materials into OLEDs for the first time. Such materials have extremely low singlet triplet energy gaps and can achieve 100% intra-theoretical quantum efficiency through inverse intersystem crossing (RISC) of triplet excitons. With the improvement of material system and device structure, OLED has emerged in the display field. On the other hand, WOLED, which incorporates "Silicon Nitride Ceramic Plate", has a series of advantages such as high luminous efficiency, adjustable spectrum, less blue light components and surface light source. As a high-efficiency light source with low color temperature and no blue pollution, it is expected to become a new trend of healthy lighting in the future.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords