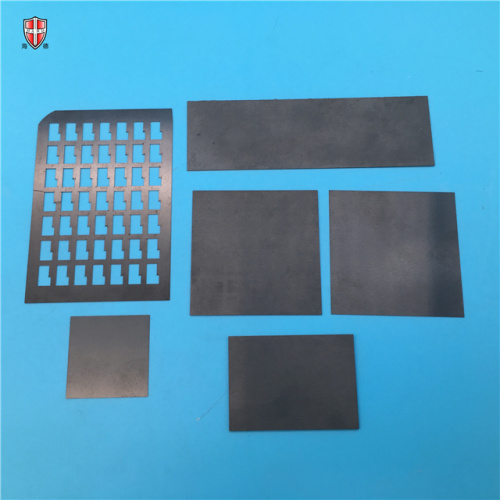

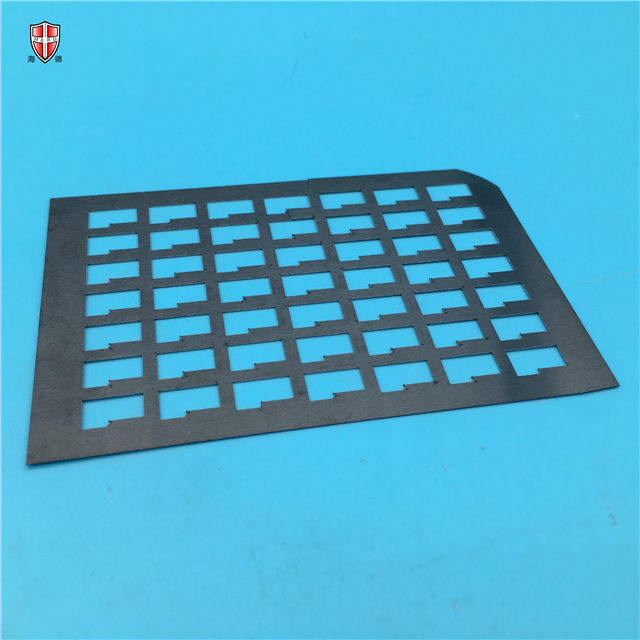

thermal heat sink silicon nitride ceramic laser cutting

-

$3.0010-99 Piece/Pieces

-

$1.00100-999 Piece/Pieces

-

$0.501000-9999 Piece/Pieces

-

$0.10≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

thermal heat sink silicon nitride ceramic laser cutting

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

Stamping parts are formed by High Precision Scribing Ceramic Substrate Sheet Thin Plate applying external force to plates, strips, pipes and profiles by means of presses and dies to produce plastic deformation or separation, thereby obtaining workpieces (stamping parts) of the required shape and size. Stamping and forging are both Alumina Ceramic Ring plastic processing (or pressure processing), collectively called forging. The stamped blanks are mainly hot-rolled and cold-rolled steel plates and strips. Of the world's steel, 60 to 70% are plates, most of which are stamped into finished products. The car body, chassis, fuel tank, radiator fins, boiler drums, container shells, motors, electrical iron core silicon steel sheets, etc. High Precision Scribing Ceramic Substrate Sheet Thin Plate are all stamped and processed. There are also a large number of stamping parts in products such Alumina Ceramic Tube as instruments, household appliances, bicycles, office machinery, and living utensils. Compared with castings and forgings, stamping parts are thin, uniform, light and strong. Stamping can produce workpieces with ribs, ribs, undulations or flanges that are Alumina Ceramic Rod difficult to manufacture by other methods to improve their rigidity. Due to the use of precision molds, the precision of the workpiece can reach the micron level, and the repeatability is high, the specifications High Precision Scribing Ceramic Substrate Sheet Thin Plate are consistent, and holes, bosses, etc. can be punched out. Cold stamping parts are generally no longer processed by cutting, or only a small amount of cutting processing is required. The precision and surface condition of hot stamping parts are lower than cold stamping parts, but still better than castings and forgings, and the cutting amount is less. Stamping is an efficient production method. Using compound dies, especially multi-station progressive dies, multiple stamping processes can be completed on one press, and the entire process from strip uncoiling, leveling, punching to forming and finishing can be achieved. Automatic production. High production efficiency, good working conditions, low production cost, generally hundreds of pieces per minute can be produced.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords