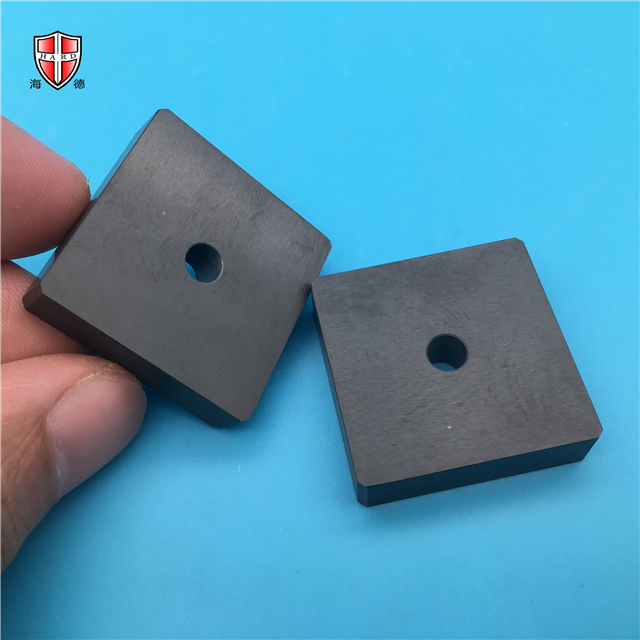

advanced technical engineering Si3N4 ceramic blank block

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

advanced technical engineering Si3N4 ceramic blank block

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

The concept of ceramics has developed into a sintered body that can be obtained by three-dimensional bonding of materials through molding and high-temperature sintering. (This concept also includes glass in the scope of ceramics)

The theory of studying the structure and properties of ceramics has also been developed: ceramic materials, the influence of internal microstructures (microcrystalline crystal surface effect, porous multiphase distribution) on mechanical properties has been developed. The relationship between the properties of materials (optical, electrical, thermal, and magnetic) and the forming, as well as the particle size distribution, and the relationship between the adhesive interface have also been developed. Ceramics should become a form of material that carries certain properties. This should be related to quantum mechanics, nanotechnology, surface chemistry and other disciplines. The subject of ceramics has become a comprehensive subject. This development is to some extent related to polymer molding. They should influence each other. The titanium diboride powder is gray or gray-black and has a hexagonal (AlB2) crystal structure. Its melting point is 2980°C and it has high hardness. The anti-oxidation temperature of titanium diboride in the air can reach 1000℃, and it is stable in HCl and HF acid. Titanium diboride is mainly used to prepare composite ceramic products. Because of its resistance to molten metal corrosion, it can be used in the manufacture of molten metal crucibles and electrolytic cell electrodes. Titanium boride (TiB2) is the most stable compound of boron and titanium. It has a C32 structure and is combined in the form of valence bonds. It is a metalloid compound of the hexagonal crystal system. The structural parameters of the complete crystal are: a is 0.3028nm and C is 0.3228nm. In the crystal structure, the boron atom plane and the titanium atom plane alternately form a two-dimensional network structure, in which the B and the other 3 B are covalently bonded, and the extra electron forms a large π bond. This graphite-like layered structure of boron atoms and Ti outer layer electrons determine that TiB2 has good conductivity and metallic luster, and the Ti-B bond between the boron atomic surface and the titanium atomic surface determines the high hardness of this material And brittleness.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

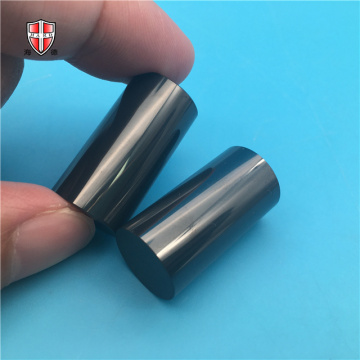

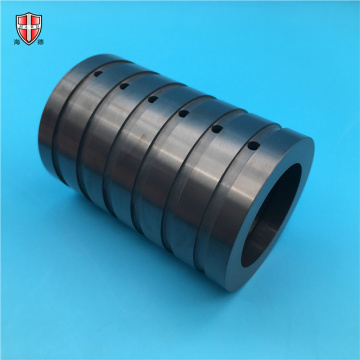

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords