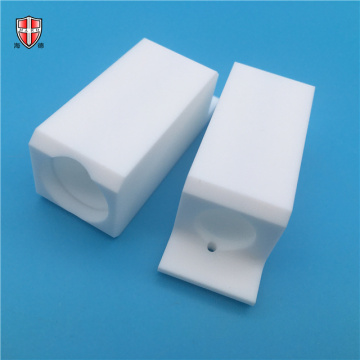

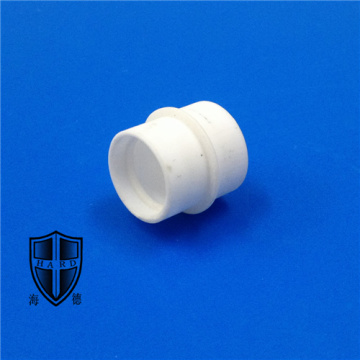

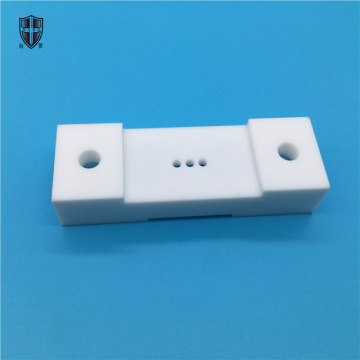

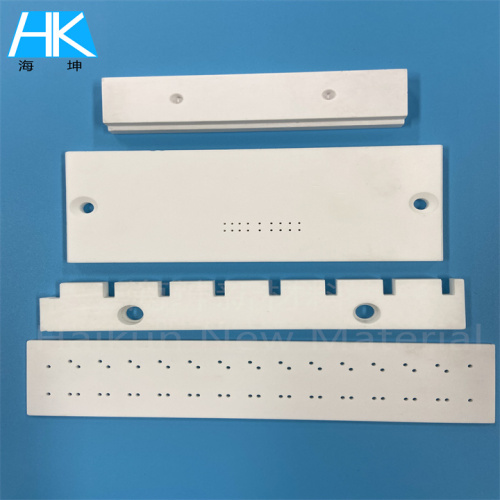

Customized Macor MGC Machinable Glass Ceramic Parts

-

$2.80≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangdong, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 100000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,Express Delivery,DDP |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangdong,Dongguan |

What's the Machinable Glass Macor Ceramic Parts?

Macor MGC, a machinable glass ceramic material developed by Corning, is known for its high strength and thermal stability, making it an excellent choice for precision components in various industries. When discussing customized Macor MGC parts, several key aspects come into play:

1. **Design Flexibility**

- **Precision**: Customized parts can be designed to meet specific functional requirements, ensuring optimal performance within your application.

- **Complexity**: The ability to create intricate shapes and features allows for the optimization of part functionality, often leading to reduced weight and improved efficiency.

2. **Material Properties**

- **Strength**: Macor MGC is highly resistant to mechanical wear and tear, ideal for parts that require durability under stress or high-temperature conditions.

- **Thermal Stability**: It maintains its properties over a wide temperature range, making it suitable for applications involving rapid heating and cooling cycles.

3. **Manufacturing Capabilities**

- **Machining**: Due to its machinability, Macor MGC allows for precise shaping through processes like milling, turning, and drilling, which are crucial for creating complex geometries.

- **Custom Fabrication**: Customized parts can be fabricated to exact specifications, including tolerances, surface finishes, and specific dimensions.

4. **Applications**

- **High-Tech Industries**: Used in aerospace, where parts need to withstand extreme environments and maintain performance.

- **Medical Devices**: Components requiring high precision and durability, such as surgical instruments or implants.

- **Optics and Electronics**: Where thermal stability and precision are critical, such as in laser systems or high-end electronic assemblies.

5. **Benefits**

- **Enhanced Performance**: Customized Macor MGC parts can significantly improve the overall performance of a system due to their tailored design and material properties.

- **Durability**: They offer longer service life compared to other materials due to their exceptional strength and resistance to wear.

- **Cost-Effectiveness**: By optimizing the part design and reducing the need for multiple components, customized Macor MGC parts can lead to cost savings in the long run.

6. **Production Process**

- **Material Preparation**: Ensuring the quality of the raw Macor MGC material is crucial before starting any manufacturing process.

- **Design and Prototyping**: Utilizing CAD software for detailed design and simulation of the part's performance under various conditions.

- **Machining**: Precise cutting and shaping using specialized machinery to achieve the desired geometry and finish.

- **Quality Control**: Rigorous testing and inspection to ensure all parts meet the specified standards and requirements.

Conclusion

Dongguan Hai Kun New Material Co.,Ltd which is specializes in kinds of customized Macor MGC machinable glass ceramic parts offer unparalleled precision, strength, and versatility across a wide range of applications. Whether you're looking to enhance the performance of existing systems or innovate new products, these parts provide a robust solution that can withstand demanding conditions while delivering optimal functionality.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords