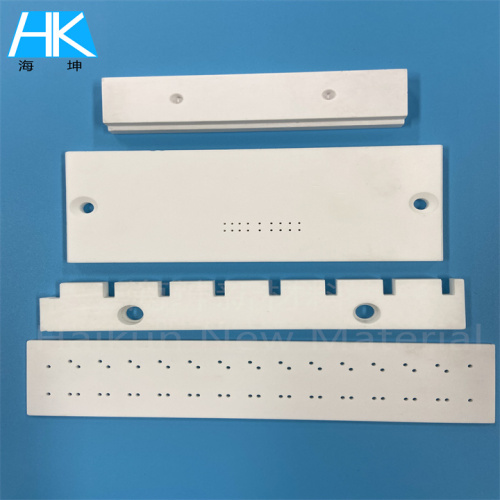

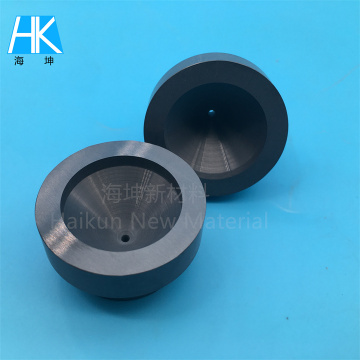

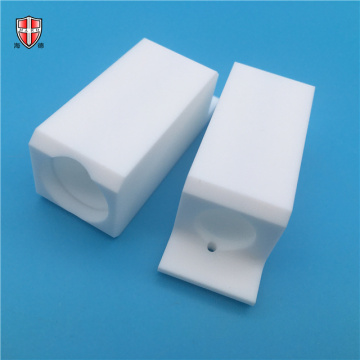

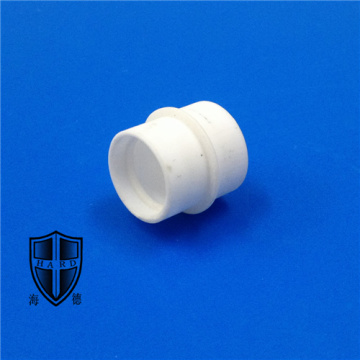

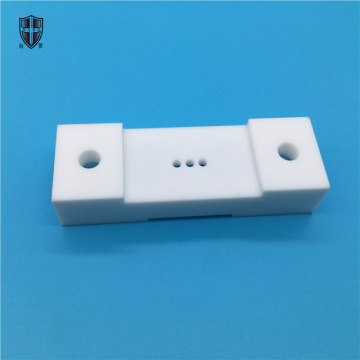

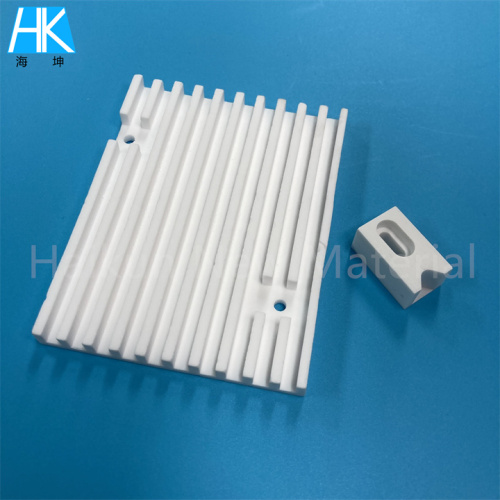

Manufacturing Machinable Glass Ceramic Macor Parts

-

$3.60≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Dongguan |

What's Macor Machinable Glass Ceramic material?

Macor is a unique type of machinable glass ceramic material, developed by General Electric. It's composed of a special blend of glasses and ceramics that allows it to be machined like metal, while maintaining its ceramic properties such as high strength, thermal stability, and resistance to chemical corrosion. This makes it particularly valuable in applications where parts need to withstand extreme conditions or require precise dimensions.

Applications of Macor Parts:

1. **Aerospace Industry**: Macor is used in aerospace components due to its high temperature resistance, electrical insulation, and dimensional stability. It can be found in parts like turbine blades, engine components, and heat exchangers.

2. **Medical Devices**: Its biocompatibility and high-temperature tolerance make it suitable for medical implants and surgical instruments.

3. **Semiconductor Industry**: In semiconductor manufacturing, Macor is used for parts that require precision and high thermal stability, such as insulators and heat sinks.

4. **Optics and Lasers**: Due to its low coefficient of thermal expansion and high optical clarity, Macor is used in precision optics and laser components.

5. **Automotive Industry**: It finds use in high-performance automotive components, especially those operating under high temperatures or stress.

Machining Macor Ceramic:

Macor can be machined using conventional methods like turning, milling, drilling, and grinding. However, because it's a ceramic, certain precautions must be taken during machining to prevent chipping or cracking. Tools should be kept sharp, and cutting speeds should be managed carefully to avoid excessive heat generation, which could damage the material.

Benefits of Using Macor Machinable Ceramic:

- **Dimensional Stability**: Macor maintains its size and shape well under varying temperatures, making it ideal for precision parts.

- **High Temperature Resistance**: It can withstand temperatures up to 1200°C (2200°F) without significant degradation.

- **Corrosion Resistance**: It resists many types of chemicals, making it suitable for harsh environments.

- **Electrical Insulation**: It provides excellent electrical insulation, which is beneficial in electronic and electrical applications.

Machinable Glass Ceramic Manufacturing Process:

The creation of Macor involves mixing various types of glasses and ceramics, then extruding or casting this mixture into the desired shape before sintering at high temperatures to fuse the components together. The final product is then cooled slowly to ensure structural integrity.

Conclusion:

Macor's combination of mechanical properties, chemical resistance, and high-temperature capability makes it an attractive material choice for industries requiring parts that can withstand extreme conditions. Its machinability also allows for the production of complex geometries with high precision, making it a versatile material in advanced engineering applications.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor Glass, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords