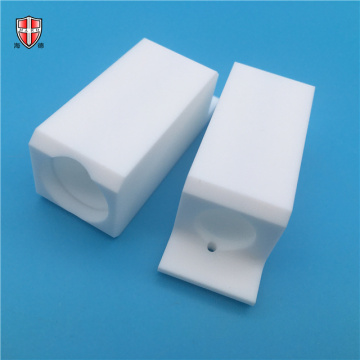

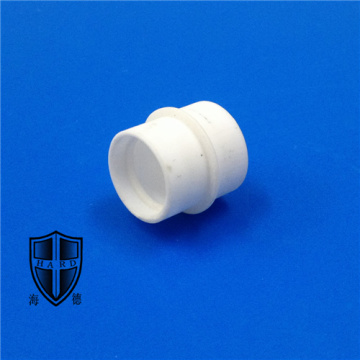

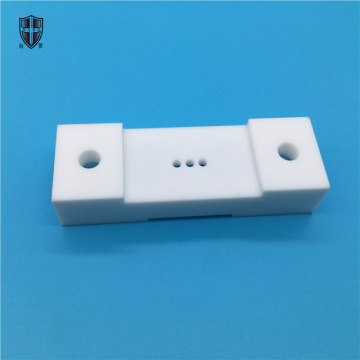

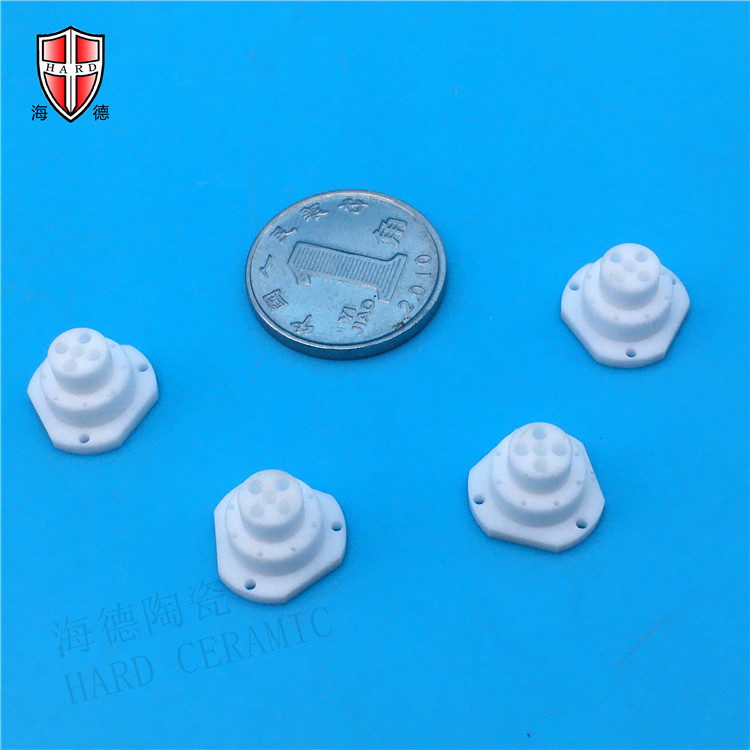

Custom insulator micro ceramic machinable structural parts

-

$1.0010-9999 Piece/Pieces

-

$0.50≥10000 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | Paypal |

|---|---|

| Incoterm: | EXW |

Manufacturers custom insulator microcrystalline ceramic machinable structural parts

Reputation depends on quality, quality comes from Hard!

Macor (Mica Glass) Ceramic:

Microcrystalline glass ceramics, also known as machinable ceramics, are mica glass-ceramics with synthetic mica as the main crystalline phase, and are ceramic materials that can be machined. Microcrystalline glass ceramics have excellent processing properties, vacuum properties, electrical insulation properties, and high temperature and chemical resistance. Glass-ceramics with high mechanical strength, glass-ceramics, machinable glass-ceramics and bioactive glass-ceramic.

Machinable Ceramic Properties:

Good insulativity, high temperature(800°) but very low thermal conductivity, good machinable property, easy to machining, can be made of rod and plate in short time.

Application industry: Machinery, electronic, limitary, aerospace etc.

Specific application: Machined equipment high temperature insulated parts, electronic equipment high temperature insulated parts.

Data Sheet↓

| Machinable Mica Glass (Macor) Ceramic Properties | ||

| Item | Unit | Typical Values |

| Physical Properties | ||

| Color | White | |

| Main Composition | Mg3K[AlF2O(SiO3)3],SiO2 | |

| Density | g/cm3 | 2.60 |

| Apparent Porosity | 0.07% | |

| Water Absorption | 0 | |

| Normal Temperature Outlet Rate | ml/S·cm2 | 8.8*10-9 |

| Helium Transmission Rate | ml/S | 1*10-10 |

| Mechanical Properties | ||

| Rockwell Hardness(45N) | R45N | 40 |

| Vickers Hardness (Load 500g) | Gpa(Kg/mm2) | 11.5(1175) |

| Flexural Strength (20°C) | Mpa | >108 |

| Compressive Strength (20°C) | Mpa | 488 |

| Modulus of Elasticity (25°C) | Gpa | 65 |

| Impact Toughness | KJ/m2 | >2.56 |

| Thermal Properties | ||

| Thermal Conductivity (25°C) | W/m.K | 1.71 |

| Thermal Expansion Coefficient | 10-6/°C | 7.2 |

| Thermal Shock Resistance | T°C | 200 |

| Maximum Working Temperature | °C | 800 |

| Electric Properties | ||

| Dielectric Strength | KV/mm | >40 |

| Volume Resistivity(25°C) | Ω.cm | 1.08*1016 |

| Volume Resistivity(200°C) | Ω.cm | 1.5*1012 |

| Volume Resistivity(500°C) | Ω.cm | 1.1*109 |

| Dielectric Loss | 1-4*10-3 | |

| Dielectric Constant | Er | 6-7 |

Dongguan Haikun New Material Co., Ltd. is a company that integrates development, design, moulding, sintering, machining and sales of precision ceramic parts. Compared with metals and plastics, ceramic materials have excellent properties such as high hardness, high strength, high temperature(fire) resistance, wear resistance, corrosion resistance, acid and alkali resistance, oxidation resistance, insulation, nonmagnetic, good chemical stability and other ec etc.

We made ceramic rods, ceramic tubes, ceramic pixcellent performance, so it is often used in the environment of the metal material is not up to. Advanced ceramics application prospect are very widely. It’s widely used in aerospace, aviation, military industry, nuclear power, machinery, textile, chemical, electronic, food, medical, etc.

For the ceramic material we machining, there have alumina (Al2O3) ceramic, zirconia (ZrO2) ceramic, silicon nitride (Si3N4) ceramic, macor (mica glass ) ceramic, aluminum nitride (AIN) ceramic, silicon carbide (SiC) ceramic, boron nitride (BN) ceramic, quartz ceramic, mullite ceramic, cordierite ceramipes, ceramic plates, ceramic sheets, ceramic blocks, ceramic nozzles, ceramic plungers, ceramic washers, ceramic spacers, ceramic substrates and precision parts for industrial.

As a leader of advanced ceramic, we have cooperated with more than 3000 companies and 60 universities at domestic and abroad.We have a higher visibility and better reputation in the same industry.

Looking forward a sincere cooperation with customers all over the world.

Why Choose Us?

1.15 years of professional production industrial ceramics factory.

2.High quality products with low price.

3.High precision parts with lowest tolerance.

4.Short time for production.

5.Has a group of experienced, professional and efficient R&D team.

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service.

Q: Are you trading company or manufacturer ?

A: We are manufacturer (factory).

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% in advance ,balance before shippment.

CONTACT US

Related Keywords