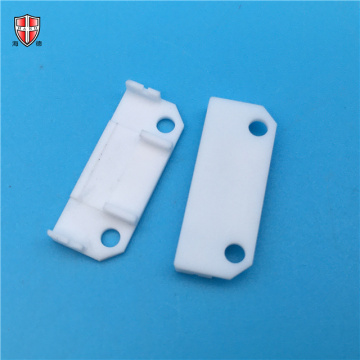

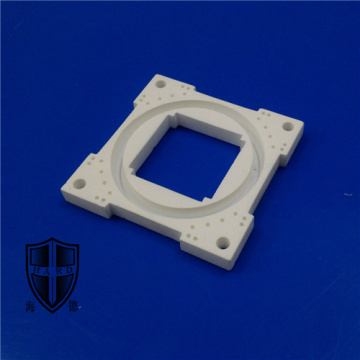

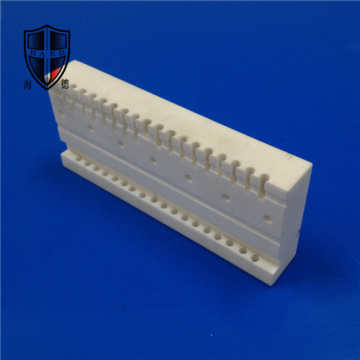

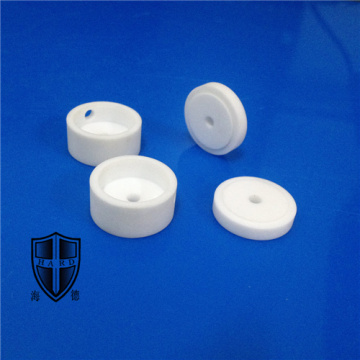

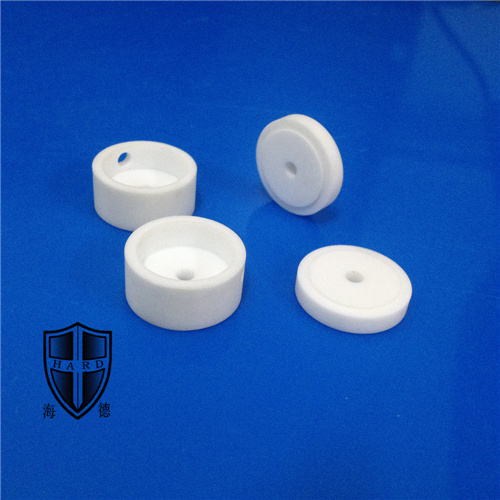

mycalex glass machinable ceramic custom made eyelet knob

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

mycalex glass machinable ceramic custom made eyelet knob

Reputation depends on quality, quality comes from Hard!

Machinable Glass Ceramic:

Daily-use ceramics play an important role in the ceramic market. They are characterized by good heat stability, chemical resistance, and aesthetics and durability. They are the first choice for people's daily life. Conventional daily-use ceramic raw materials are mostly made of a large amount of clay. When these formulas are used to produce ceramic tableware, the quality of the product is affected by the raw materials, and the thermal shock resistance and impact strength are lowered due to the low firing temperature. , affecting the quality and service life of ceramic tableware, resulting in waste of products.Glass-ceramic, also known as glass-ceramic, is a hard, dense and uniform multiphase material composed of a crystalline phase and a glass phase, which is made of glass and ceramics. Double characteristics, glass-ceramics have higher brightness than ceramics and are stronger than glass. In the prior art, there are reports on the use of glass ceramics as a ceramic co-solvent, such as CN105236993B, which also discloses the use of glass-ceramics to fire ceramic glass-ceramic composite sheets, such as CN101613217B. In the prior art, tableware is also prepared by using glass-ceramics, such as CN201510003124.X, but it still fails to fundamentally solve the shortcomings of the daily-use ceramic products in terms of thermal shock resistance and impact strength.

properties:

Good insulativity, high temperature(800°), good machinable property, can be made of rod and plate in short time.

Data Sheet↓

Color: WhiteDensity: 2.6g/cm3

Gas permeability: 0

Water Absorption: 0

Rockwell Hardness(45N): 40R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 108Mpa

Compressive Strength(20°C): 488Mpa

Modulus of Elasticity(25°C): 65Gpa

Thermal Conductivity(25°C):1.71W(m.K)

Thermal Expansion Coefficient: 7.2 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum Use Temperature: 800°C

Dielectric Strength: >30 KV/mm

Volume Resistivity(20°C): >10(16)Ω.cm

Application industry:

Machinery, electronic, limitary, aerospace etc.

Specific application:

Machined equipment high temperature insulated parts, electronic equipment high temperature insulated parts.

Company Information:

Shenzhen Hard Precision Ceramic CO.,Ltd founded in 2007, located in Shenzhen of China. We are a company that integrates development, design, molding, sintering, production and sales of precision ceramic products. After 10 years of development, we have cooperated with more than 2000 customers and 60 universities; Our factory covers an area of 2000 square meters, 50 employees, and annual production value of nearly 20 million. We have a higher visibility and better reputation in the same industry.Our products include ceramic rods, tubes, plates, blocks and precision parts for industrial. We have all-line high precision equipments from ceramic forming, sintering to precision machining. Hope for a wide range of sincere cooperation with customers at home and abroad.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Show time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

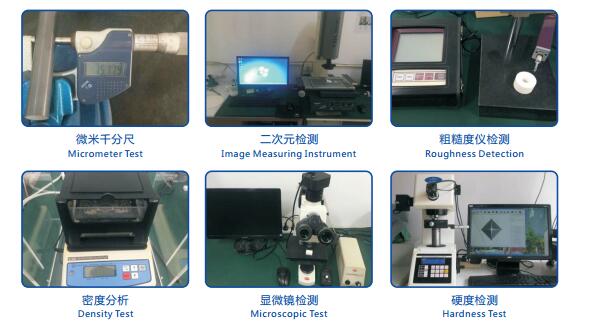

Factory Show

Our Team

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords