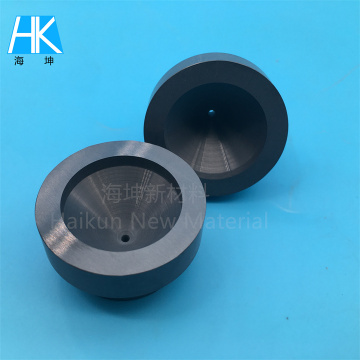

White Mechining Macor Glass Ceramic Customized Parts Components

-

$2.99≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, GUANGZHOU

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000PCS/MONTH |

|---|---|

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CIF,EXW,Express Delivery |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,GUANGZHOU |

Macor ceramics are very unique and useful materials that possess several compelling properties.

1. Excellent Mechanical Performance and Applications

Advanced ceramics exhibit exceptional mechanical characteristics, including high hardness, strength, and excellent compressive resistance. These properties make advanced ceramics an ideal choice for many industrial applications, especially in environments requiring materials to withstand extreme forces and wear.

- High Hardness and Strength:

- Rockwell Hardness: R45N is 40.

- Vickers Hardness (500g load): 11.5 GPa (1175 Kg/mm²).

- Modulus of Elasticity: At 25°C, the modulus of elasticity is 65 GPa.

- Flexural Strength: At 20°C, the flexural strength is 108 MPa.

- Compressive Strength: At 20°C, the compressive strength is 488 MPa.

These mechanical properties enable advanced ceramics to maintain stability under impact and stress, reducing the risk of fracture. Due to their high strength and wear resistance, advanced ceramics are commonly used to manufacture various high-performance industrial components such as parts in milling machines, sliding components, and cutting tool blades.

2. Outstanding Thermal Properties

Advanced ceramics also possess excellent thermal properties, including high temperature stability, low thermal expansion coefficient, and good thermal shock resistance.

- Maximum Operating Temperature: The maximum operating temperature is 800°C.

- Thermal Conductivity: At 25°C, thermal conductivity is 1.71 W/(m·K).

- Thermal Expansion Coefficient: The thermal expansion coefficient is 7.2 × 10⁻⁶/°C.

- Thermal Shock Stability: Thermal shock stability is 200°C.

These characteristics make advanced ceramics very useful in applications requiring insulation or thermal protection. For example, in certain chemical processing equipment and high-temperature furnaces, advanced ceramics can be used as thermal barrier coatings to help control temperature and protect sensitive mechanical components from overheating damage.

3. Excellent Electrical Performance

Advanced ceramics also demonstrate excellent electrical insulation properties, making them highly valuable in electronic and electrical applications.

- Breakdown Strength (Dielectric Strength): The breakdown strength is 30 KV/mm.

- Volume Resistivity at 20°C: At 20°C, the volume resistivity is 10¹⁶ Ohm·cm.

These electrical properties make advanced ceramics very effective in high-voltage and high-frequency applications, providing reliable insulation protection.

This type of advanced ceramic material excels in various demanding application environments, particularly in fields requiring high hardness, strength, exceptional thermal, and electrical performance.

Related Keywords