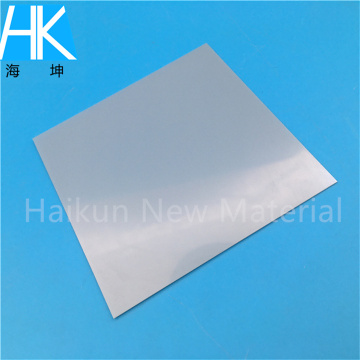

high thermal Aluminum Nitride Ceramic Substrate Wafer

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

high thermal Aluminum Nitride Ceramic Substrate Wafer

Reputation depends on quality, quality comes from Hard!

Aluninum Nitride Ceramic:

Due to the different uses of aluminum nitride ceramic products, the processing technology and raw material quality requirements are also different. Generally speaking, different stainless steel products require different thickness tolerances of raw materials. For example, the thickness tolerance of the second type tableware and the vacuum flask is generally higher, which is -3~5%, while the thickness tolerance of the first type tableware is generally required- 5%, steel pipe category requires -10%, hotel freezer material thickness tolerance is -8%, distributors generally require thickness tolerance between -4% and 6%. At the same time, the difference between the internal and external sales of products will also lead to the different requirements of customers on the thickness tolerance of raw materials. Generally, customers of export products have relatively high thickness tolerance requirements, while domestic sales companies have relatively low requirements for thickness tolerance (mostly due to cost considerations), and some customers even require -15%. DDQ (deep drawing quality) material: refers to the material used for deep drawing (punching) purposes, also known as soft material, the main feature of this material is high elongation (≧53%) and hardness Low (≦170%), the internal grain grade is between 7.0 and 8.0, and the deep drawing performance is excellent. Many companies that produce thermos flasks and pots generally have relatively high product processing ratios (BLANKING SIZE/product diameter), and their processing ratios are 3.0, 1.96, 2.13, and 1.98 respectively. SUS304DDQ materials are mainly used for these products that require a higher processing ratio. Of course, products with a processing ratio of more than 2.0 generally require several passes of stretching to complete. If the extension of the raw materials cannot be achieved, the products are prone to cracks and pull-through phenomena when processing deep-drawn products, which will affect the qualified rate of finished products and of course increase the cost of the manufacturer;

Aluminum nitride has high hardness and exceeds traditional alumina. It is a new type of wear-resistant ceramic material, but it can only be used for severely worn parts due to its high cost.

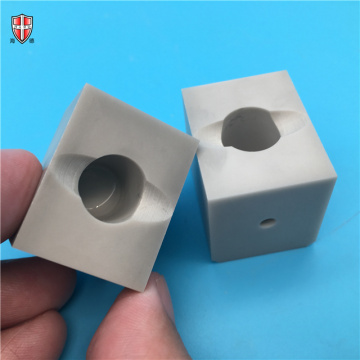

Using AIN ceramics for heat resistance, melt erosion and thermal shock resistance, GaAs crystal crucible, Al evaporating dish, magnetic fluid power generation device and high temperature turbine corrosion resistant parts can be fabricated, and its optical properties can be used as an infrared window. The aluminum nitride film can be made into a high frequency piezoelectric element, a very large scale integrated circuit substrate, or the like.

Aluminum nitride heat-resistant, resistant to molten metal erosion, stable to acid, but easy to be eroded in alkaline solution. The AIN fresh surface is exposed to moist air and reacts to form a very thin oxide film. By utilizing this property, it can be used as a crucible and a die-casting mold material for smelting metals such as aluminum, copper, silver, and lead. AIN ceramics have good metallization properties and can be widely used in the electronics industry as an alternative to toxic cerium oxide.

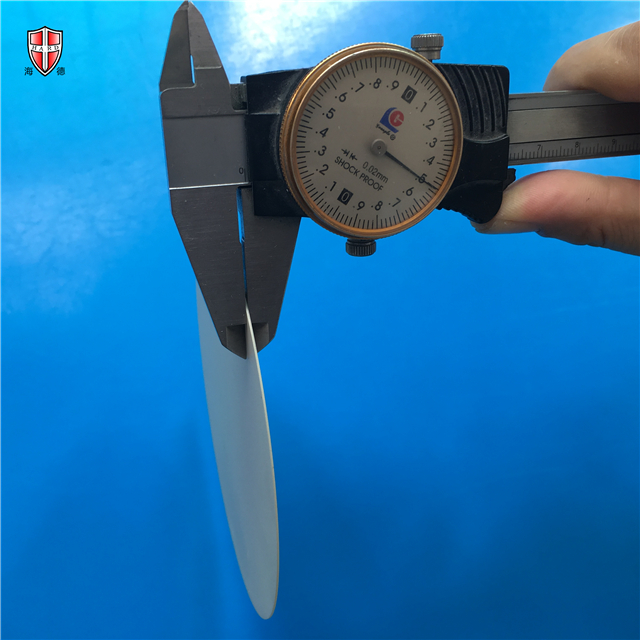

Data Sheet:

Ø (1) high thermal conductivity (about 320W / m · K), close to BeO and SiC, more than 5 times that of Al2O3;

Ø(2) The thermal expansion coefficient (4.5×10-6°C) is matched with Si (3.5-4×10-6°C) and GaAs (6×10-6°C);

Ø (3) excellent electrical properties (dielectric constant, dielectric loss, volume resistivity, dielectric strength);

Ø(4) good mechanical properties, higher flexural strength than Al2O3 and BeO ceramics, can be sintered at normal pressure;

Ø (5) good optical transmission characteristics;

Ø(6) non-toxic;

Application industry:

Aluminum nitride powder has high purity, small particle size and high activity, and is the main raw material for manufacturing high thermal conductivity aluminum nitride ceramic substrate.

Aluminum nitride ceramic substrate, high thermal conductivity, low expansion coefficient, high strength, high temperature resistance, chemical corrosion resistance, high resistivity, small dielectric loss, is an ideal large-scale integrated circuit heat sink substrate and packaging materials.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords