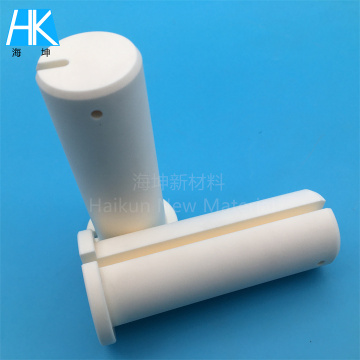

high temperature custom 99.5 alumina ceramic machined parts

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

high temperature custom 99.5 alumina ceramic machined parts

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The structure of alumina ceramics includes graft copolymers with elastomer as the main chain and graft copolymers with hard ABS resin as the main chain; or a mixture of rubber elastomer and hard ABS resin. In this way, different structures show different properties, elastomers show the toughness of rubber, and hard ABS resins show rigidity, and several varieties such as high impact type, medium impact type, general impact type and special impact type are available. Specifically, as the content of rubber component B (generally 5% to 30%) increases, the elasticity and impact resistance of the resin will increase; but the tensile strength, fluidity, and weather resistance will decrease. As the content of the resin component AS (generally 70%-95%) increases, the surface gloss, mechanical strength, weather resistance, heat resistance, corrosion resistance, electrical properties, and processing properties can be improved. The impact strength etc. will be reduced. The ratio of A and B in the resin component is 30%~35%/80%~65% respectively. Plastic ABS resin is the polymer with the largest output and the most widely used. It organically unifies the various properties of PB, PAN, and PS, and has excellent mechanical properties of toughness, hardness and rigidity. ABS is a terpolymer of acrylonitrile, butadiene and styrene. A stands for acrylonitrile, B stands for butadiene, and S stands for styrene. After actual use, it was found that: ABS plastic pipes are not resistant to sulfuric acid corrosion, and smashed and cracked when encountered with sulfuric acid.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords