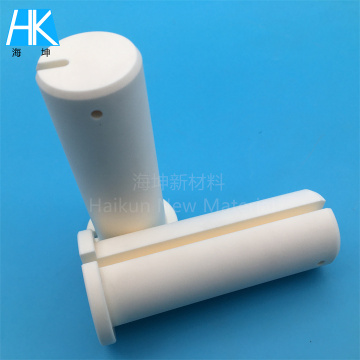

electronic insulating alumina ceramic milling insert bar

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

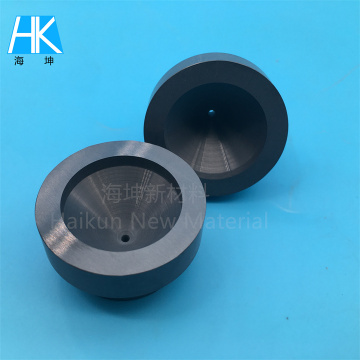

custom engineering aluminum oxide ceramic machining parts

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

In the industrial production of alumina ceramics, the foaming process is carried out by placing expandable PS directly in steam. Generally, the reaction is completed by continuous mixing of beads and steam in a stirred tank. The reaction equipment (like a pre-foaming machine) is In order to maintain the external pressure and atmospheric pressure, and make the foamed beads overflow from the top. Some production plants use intermittent kettles to ensure a more balanced residence time or when higher temperatures are required for certain expandable DPS. After foaming, the beads must undergo aging treatment to gradually incorporate air into the cells.

The second step. First, put the matured pre-expanded beads into a mold with a specific cavity. For small and complex structure products, venturi action equipment (such as filling gun) should be used when forming. The beads are blown into the mold cavity by means of air flow. Large-scale products can fill the cavity according to their own gravity. The mold cavity filled with pellets is sealed and heated, the beads are softened by the heat, and the cells expand. The beads expand to fill the gaps between each other and bond to form a uniform foam. At this time, the foam is still soft and bears the pressure of the hot gas in the cells. Before taking out the product from the mold, the gas must be allowed to seep out of the cells and the temperature must be lowered to stabilize the shape of the product. This is generally done by spraying water on the inner wall of the mold.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords