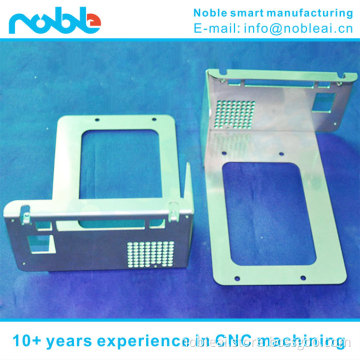

China CNC machined aluminum alloy intelligent wheelchair power fixture parts

- Payment Type:

- T/T, Paypal

- Incoterm:

- FOB, EXW

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, EXPRESS

- Port:

- SHENZHEN

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | CHINA |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Air,EXPRESS |

| Port: | SHENZHEN |

Product Description

Product Description

Project Quick details

Parts applications: the intelligent wheelchair power fixture

Material: Aluminum alloy A356.2, etc.

Manufacturing Process: NC bending technique+ Laser spot welding

Finish Treatment: Anodic Oxidation

Difficulties & Highlights: High precision

Size: Customer`s 3D/2D drawing

Brand name: Noble

Palace of origin: Shenzhen, China (mainland)

Anodic oxidation is the electrochemical oxidation of metal or alloy. Aluminum and its alloys are formed in the corresponding electrolyte and certain technological conditions under the action of the external current, forming an oxide film on the aluminum product (anode). the surface of aluminum and aluminum alloys is usually converted to an oxide film with protective during the process, this oxide film has decorative and other functional properties.

Our Equipment

We take the CNC machining as core technology, meanwhile, we integrate other upstream and downstream resources in our industrial chain to provide service for the customer.

We have 4 five-axis CNC, more than 30 high-speed CNC machining centers, CNC lathes, CNC carved machines, in total we have more than 50 machining equipment.

Quality control:

We will provide all documents as you need such as inspection report, material report, etc. To meet your quality requirements of products and parts.

After-sale service:

If the parts have any quality problems when you got them, no matter it happened when we made them or caused by the delivery, we will try best to help you to solve the problems and take our part of responsibility, so you will be free from worries.

Parts applications: the intelligent wheelchair power fixture

Material: Aluminum alloy A356.2, etc.

Manufacturing Process: NC bending technique+ Laser spot welding

Finish Treatment: Anodic Oxidation

Difficulties & Highlights: High precision

Size: Customer`s 3D/2D drawing

Brand name: Noble

Palace of origin: Shenzhen, China (mainland)

What can we do?

Production process

Anodic oxidation is the electrochemical oxidation of metal or alloy. Aluminum and its alloys are formed in the corresponding electrolyte and certain technological conditions under the action of the external current, forming an oxide film on the aluminum product (anode). the surface of aluminum and aluminum alloys is usually converted to an oxide film with protective during the process, this oxide film has decorative and other functional properties.

Our Equipment

We take the CNC machining as core technology, meanwhile, we integrate other upstream and downstream resources in our industrial chain to provide service for the customer.

We have 4 five-axis CNC, more than 30 high-speed CNC machining centers, CNC lathes, CNC carved machines, in total we have more than 50 machining equipment.

We are able to provide machining service of CNC milling, turning, engraving, cutting, tapping, drilling, etc.

Quality control:

We will provide all documents as you need such as inspection report, material report, etc. To meet your quality requirements of products and parts.

After-sale service:

If the parts have any quality problems when you got them, no matter it happened when we made them or caused by the delivery, we will try best to help you to solve the problems and take our part of responsibility, so you will be free from worries.

Related Keywords

Related Keywords

You May Also Like

You May Also Like