A basic introduction to automotive wiring

- Payment Type:

- T/T

- Min. Order:

- 10 Bag/Bags

- Min. Order:

- 10 Bag/Bags

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- SHENZHEN, Guangzhou, Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | China |

| Supply Ability: | good |

| Payment Type: | T/T |

| Transportation: | Ocean,Land,Air |

| Port: | SHENZHEN,Guangzhou,Shanghai |

Product Description

Product Description

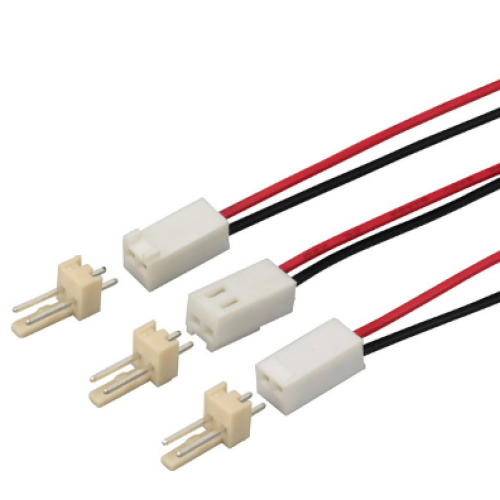

The car wire is also known as the low voltage wire, which is different from the normal household electric wire. Common household wire is copper single - tipped wire, with a certain hardness. The electric wires are all copper and tipped with soft wires, some of which are as thin as hair, and a few or even dozens of soft copper wires are wrapped in plastic insulated tubes (polyvinyl chloride) that are soft and not easily broken.

Because of the particularity of automobile industry, the manufacturing process of automobile wire harness is more special than that of other ordinary lines.

There are two types of systems for making car wiring:

1. The division of European and American countries, including China:

Use the TS16949 system to control the manufacturing process.

2. Mainly Japan:

Toyota and Honda have their own systems to control the manufacturing process.

With the increase of automobile function, the general application of electronic control technology, more and more electrical parts, and more and more wires, the thicker and heavier the wiring. Therefore, the advanced car introduces CAN bus configuration and multiplex transmission system. Compared with the traditional linear beam, the multiplex device greatly reduces the number of wires and the number of linked plug-ins, making the wiring easier.

The commonly used

Automotive wiring harness commonly used specifications of wire nominal cross-sectional area 0.5, 0.75, 1.0, 1.5, 2.0, 2.5, 4.0, 6.0 mm2 wire (Japanese that is commonly used in nominal cross-sectional area is 0.5, 0.85, 1.25, 2.0, 2.5, 4.0, 6.0 mm2), they are allowed to load current value, with different power wire of electrical equipment. For example, the 0.5 specification line is suitable for instrument lamp, indicator lamp, door lamp, overhead light, etc. The 0.75 specification line applies to the license plate lamp, before and after the small light, brake lamp, etc.; The 1.0 specification line is suitable for turning on lamp, fog lamp, etc. 1.5 specification line for headlights, horns, etc. The main power source line such as generator armature line, wire line and other requirements 2.5 to 4 square mm wire. This just refers to general motors, the key depends on the load of the maximum current value, such as battery by iron wire, the positive power cord is a special car wire used alone, both wire diameter is larger, there are at least ten square millimeter above, these "big MAC" wire will not be codified in the main beam.

arrangement

The wiring diagram is not the same as the schematic diagram of the wiring diagram. Circuit principle diagram is describe the various electrical part of the relationship between the image, it does not reflect the electrical parts how to connect with each other, not affected by the size of the various electrical components shape, and the influence of the distance between them. The wiring diagram must take into account the dimensions of the electrical components and the distances between them, and also reflect how the electrical components are connected to each other.

The technician based on the wiring harness diagram is used to line the wiring board, and the worker will line the line according to the rules of the line. The main line of the vehicle is generally divided into engines (ignition, electric spraying, power generation, starting), meters, lighting, air conditioning, auxiliary appliances, etc., with main lines and branches. A main line of the vehicle has several branches, like a tree rod with a branch. The main line of the vehicle tends to be the central part of the dashboard. Because length relationship or assembly is convenient wait for a reason, some automotive wiring harness into car wiring harness, including instrumentation, air conditioning, battery, engine, before the light assembly), the rear of the wiring harness (taillight assemblies, license plate lamp, trunk lamp), tent, wiring harness, dome light, speakers (door), etc. Wire on each end will sign on Numbers and letters, to indicate the wire connection object, the operator can see mark properly connected to the corresponding wiring and electrical device, which is especially useful when repair or replace the wiring harness. At the same time, the color of the wire is divided into monochrome and double color lines, and the use of color is also regulated, which is generally the standard of the auto factory. China's industry standard only stipulates the main color, for example, the specification of single black is dedicated to the line, red and monochrome are used for power lines, not to be confused.

The cord is wrapped in woven wire or plastic tape, which is convenient for safety, processing and maintenance, and is now wrapped in sticky plastic tape. Connection between wire harness and wire harness, wire harness and electrical parts, using a linked plug-in or wire ear. The connector is made of plastic and has a plug and socket. The wire harness is connected with the harness, and the connection between the wire harness and the electrical parts is connected by a connector or wire ear.

Because of the particularity of automobile industry, the manufacturing process of automobile wire harness is more special than that of other ordinary lines.

There are two types of systems for making car wiring:

1. The division of European and American countries, including China:

Use the TS16949 system to control the manufacturing process.

2. Mainly Japan:

Toyota and Honda have their own systems to control the manufacturing process.

With the increase of automobile function, the general application of electronic control technology, more and more electrical parts, and more and more wires, the thicker and heavier the wiring. Therefore, the advanced car introduces CAN bus configuration and multiplex transmission system. Compared with the traditional linear beam, the multiplex device greatly reduces the number of wires and the number of linked plug-ins, making the wiring easier.

The commonly used

Automotive wiring harness commonly used specifications of wire nominal cross-sectional area 0.5, 0.75, 1.0, 1.5, 2.0, 2.5, 4.0, 6.0 mm2 wire (Japanese that is commonly used in nominal cross-sectional area is 0.5, 0.85, 1.25, 2.0, 2.5, 4.0, 6.0 mm2), they are allowed to load current value, with different power wire of electrical equipment. For example, the 0.5 specification line is suitable for instrument lamp, indicator lamp, door lamp, overhead light, etc. The 0.75 specification line applies to the license plate lamp, before and after the small light, brake lamp, etc.; The 1.0 specification line is suitable for turning on lamp, fog lamp, etc. 1.5 specification line for headlights, horns, etc. The main power source line such as generator armature line, wire line and other requirements 2.5 to 4 square mm wire. This just refers to general motors, the key depends on the load of the maximum current value, such as battery by iron wire, the positive power cord is a special car wire used alone, both wire diameter is larger, there are at least ten square millimeter above, these "big MAC" wire will not be codified in the main beam.

arrangement

The wiring diagram is not the same as the schematic diagram of the wiring diagram. Circuit principle diagram is describe the various electrical part of the relationship between the image, it does not reflect the electrical parts how to connect with each other, not affected by the size of the various electrical components shape, and the influence of the distance between them. The wiring diagram must take into account the dimensions of the electrical components and the distances between them, and also reflect how the electrical components are connected to each other.

The technician based on the wiring harness diagram is used to line the wiring board, and the worker will line the line according to the rules of the line. The main line of the vehicle is generally divided into engines (ignition, electric spraying, power generation, starting), meters, lighting, air conditioning, auxiliary appliances, etc., with main lines and branches. A main line of the vehicle has several branches, like a tree rod with a branch. The main line of the vehicle tends to be the central part of the dashboard. Because length relationship or assembly is convenient wait for a reason, some automotive wiring harness into car wiring harness, including instrumentation, air conditioning, battery, engine, before the light assembly), the rear of the wiring harness (taillight assemblies, license plate lamp, trunk lamp), tent, wiring harness, dome light, speakers (door), etc. Wire on each end will sign on Numbers and letters, to indicate the wire connection object, the operator can see mark properly connected to the corresponding wiring and electrical device, which is especially useful when repair or replace the wiring harness. At the same time, the color of the wire is divided into monochrome and double color lines, and the use of color is also regulated, which is generally the standard of the auto factory. China's industry standard only stipulates the main color, for example, the specification of single black is dedicated to the line, red and monochrome are used for power lines, not to be confused.

The cord is wrapped in woven wire or plastic tape, which is convenient for safety, processing and maintenance, and is now wrapped in sticky plastic tape. Connection between wire harness and wire harness, wire harness and electrical parts, using a linked plug-in or wire ear. The connector is made of plastic and has a plug and socket. The wire harness is connected with the harness, and the connection between the wire harness and the electrical parts is connected by a connector or wire ear.

Related Keywords

Related Keywords