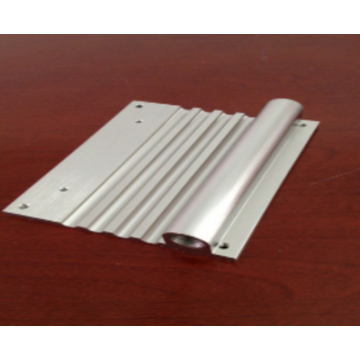

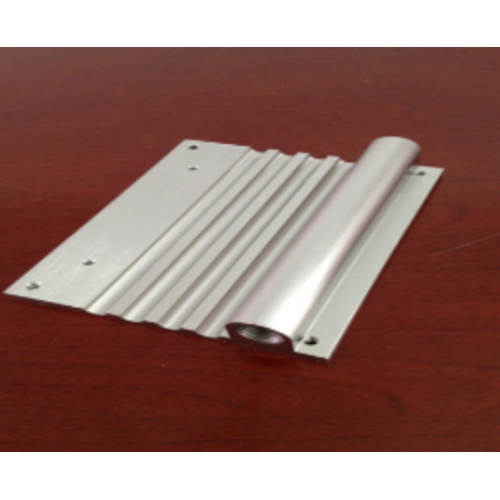

Electroplating plant local electroless nickel plating

- Payment Type:

- T/T

- Min. Order:

- 10 Bag/Bags

- Min. Order:

- 10 Bag/Bags

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- SHENZHEN, Guangzhou, Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | China |

| Supply Ability: | good |

| Payment Type: | T/T |

| Transportation: | Ocean,Land,Air |

| Port: | SHENZHEN,Guangzhou,Shanghai |

Product Description

Product Description

Local electroplating need adjust measures to local conditions, flexible, according to parts of shape, size, plating requirements to choose insulation methods, such as the insulation of the common method has the following kinds: dressing method, block insulation method, embedded insulation method, wax, cap sleeve insulation and pillaging the paint, plastic pipe, partial dissolution method, screw hole insulation method, process inversion method and so on.

There are various kinds of plating of local electroplating, such as local anodizing, local electrogalvanizing, local silver plating and gold, etc. This paper introduces the new process of shielding nickel-plated nickel by electroplating of yongyi electroplating in shenzhen electroplating plant.

Local chemical nickel plating new technology:

The electroless plating can be divided into all plating and local plating. Many local plating parts will need on the non coated insulation protection, this is about to use different local insulation method to meet the technical requirements of construction, to ensure that the components of plating not plating coating on the surface, especially for parts with special requirements.

Local electroless nickel plating principle:

The new type of electroless nickel plating process is the process of insulating the non-coated surface of the non-plated surface with the resistance of high temperature and acid alkali.

Local plating shielding methods using traditional bandaging method, special fixture method, coating insulation method, wax protection, usually will appear not resistant to high temperature, leakage blocking areas on plating coating, plating solution influence the effect of local chemical nickel plating.

Local electroless nickel plating characteristics:

(1) the products are coated without pollution, smooth and uniform in color;

(2) the non - plated surface without solution infiltrates the plating layer and the insulation is good;

(3) the product size and geometry are not limited, high temperature resistance, acid and alkali resistance, and high shielding accuracy;

(4) comply with international environmental safety standards and eu RoHS standards.

Application scope of local chemical nickel plating:

(1) electronics and communications products;

(2) aviation, aerospace, energy and medical chemical equipment;

(3) automobile, hardware and plastic mould;

(4) precision machine and part size repair.

Even local electroplating method is varied, but in order to achieve good local plating effect also has the certain difficulty, because the shape of each part size, structure is different, also have their own quality requirement. Therefore, it is necessary to have rich experience in plating and advanced technical requirements. At the same time, the technical requirements of local electroless nickel plating are more stringent.

There are various kinds of plating of local electroplating, such as local anodizing, local electrogalvanizing, local silver plating and gold, etc. This paper introduces the new process of shielding nickel-plated nickel by electroplating of yongyi electroplating in shenzhen electroplating plant.

Local chemical nickel plating new technology:

The electroless plating can be divided into all plating and local plating. Many local plating parts will need on the non coated insulation protection, this is about to use different local insulation method to meet the technical requirements of construction, to ensure that the components of plating not plating coating on the surface, especially for parts with special requirements.

Local electroless nickel plating principle:

The new type of electroless nickel plating process is the process of insulating the non-coated surface of the non-plated surface with the resistance of high temperature and acid alkali.

Local plating shielding methods using traditional bandaging method, special fixture method, coating insulation method, wax protection, usually will appear not resistant to high temperature, leakage blocking areas on plating coating, plating solution influence the effect of local chemical nickel plating.

Local electroless nickel plating characteristics:

(1) the products are coated without pollution, smooth and uniform in color;

(2) the non - plated surface without solution infiltrates the plating layer and the insulation is good;

(3) the product size and geometry are not limited, high temperature resistance, acid and alkali resistance, and high shielding accuracy;

(4) comply with international environmental safety standards and eu RoHS standards.

Application scope of local chemical nickel plating:

(1) electronics and communications products;

(2) aviation, aerospace, energy and medical chemical equipment;

(3) automobile, hardware and plastic mould;

(4) precision machine and part size repair.

Even local electroplating method is varied, but in order to achieve good local plating effect also has the certain difficulty, because the shape of each part size, structure is different, also have their own quality requirement. Therefore, it is necessary to have rich experience in plating and advanced technical requirements. At the same time, the technical requirements of local electroless nickel plating are more stringent.

Related Keywords

Related Keywords