Quality Control Coffee manchine Inspection

Your message must be between 20 to 2000 characters

Contact Now

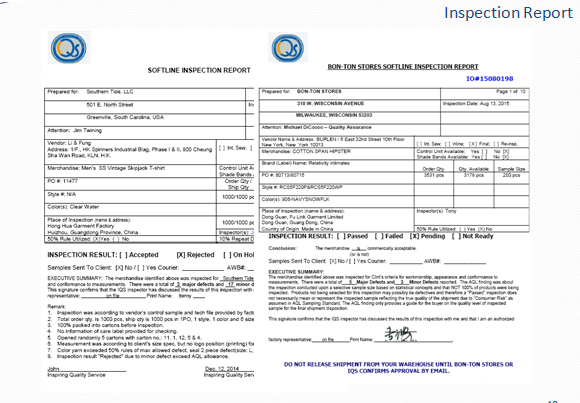

Product inspections allow to check production at any stage, especially before client sends out the balance payment to suppliers. By performing a product inspection, you ensure that there would be no surprise at destination when opening the boxes.

The inspector would check all your requirements and the specificities of your product, and give a status of your production in the inspection report. The goal is to catch issues and have them corrected, reworked or replaced by factory before shipment as there is no return policy with Asian suppliers, even less so in China. So it is fundamental to check whether the production is acceptable before it leaves the factory. Quality Control Partners Ltd. offers all types of product inspection before shipment.

IQS Inspection type:

- Initial Production Inspection(IPI)

- During Production Inspection(DPI)

- Production Monitoring(PM)

- Final Random Inspection(at least 80% package finished)(FRI)

- Container Loading Supervision(CLS)

- Factory Evaluation(FE)

- Social Assessment(SA)

IQS Inspection Service Ranges:

Softlines: Textile, Apparel & Garments/ Fashion Accessories & Bags/ Children & Baby Clothes/ Underwear & Headwear/ Plush toys/ Fabric & yarn/ Shoes & footwear/ Leather, Rubber & Latex goods

Hardlines: Furniture & furnishings/ Homeware & Gardenware/ Building material/ Industrial & Construction/ Sports Equipment/ Gifts & Crafts/ Porcelain & ceramics/ Stationery & Office supplies

Electrical & Electronics: Consumer Electronics/ Home appliances/ Lights& bulbs/ Kitchen wares/ Computer & Tablet/ Testing equipment/ IT & Telecom/ Audio & Video

Mechanical Products: Auto Parts/ Casting & Forging/ Hydraulic Components/ Machinery & Engine Pump/ Metal Components and Assemblies/ Casting & plastic Moulds/ Scrap Metal.

Related Keywords