High Heel Ivory Bridal Shoes Lace

-

USD271-9 Pair

-

USD2510-49 Pair

-

USD1750-99 Pair

-

USD15≥100 Pair

- Payment Type:

- L/C, T/T, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Pair

- Min. Order:

- 1 Pair

- Delivery Time:

- 10 Days

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Yantian, Shekou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 300 Pairs/Day |

| Supply Ability: | 500 Pairs/Day |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CIF |

| HS Code: | 64041900 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Yantian,Shekou,Hongkong |

Wedopus is our own brand, dedicated to helping brides find their dream custom wedding shoes. Our dream is that create the first brand among the global bridal shoes lace.

Do you know know how to make our shoes?

Step 1: Cutting the pattern

Pattern cutting involves creating the shape of each component of the shoe. With all our possible shoe combinations and each shoe size requiring a new pattern. An upper is the part of the shoe that sits on top of the foot.

Step 2: Tools of the trade

One of the most important tools for making a shoe is the last, something which customers never normally get to see! The last is a foot shaped piece of material over which the shoes are molded. A different last is used for each shoe size and style. For example, a shoe with a pointy toe will be molded using a last with a pointy toe. The last is so important because it determines the fit and feel of the shoes.

Step 3: Edging

Edging is the process of flattening the edge of the pieces of leather that have been cut to the pattern so it is thinner than the rest of the leather piece. This makes for crisp, neat joins between pieces of leather giving you a much more comfortable fit as well as the quality finish you would expect from a pair of hand crafted shoes.

Step 4: Stitching

The different parts of the shoe are then carefully stitched together.

Step 5: Trimming preparation

The next step is to prepare the trimming before it is added to the shoes.

Step 6: Selecting the heel

What size heel would you like? Our stiletto heels come in different shapes and sizes, and you get to pick! These become the core of the heel of your shoe - encased in the leather you have chosen.

Step 7: Trimming the excess

This involves carefully putting together and making the finishing touches to the decorative upper for another pair of hand made shoes.

Step 8: Preparing the sole

The core pieces of the sole of the shoe are then covered either side by the insole (the piece that sits against your foot) and the outersole (the piece that sits against the ground).

Step 9: Shoes of Logo

The Shoes of your own logo is lovingly added to your shoes.

Step 10: Affixing the outersole

The outersole is the affixed to the shoe.

Step 11: Finishing

The final cutting, cleaning and polishing of the shoes. The shoes are then boxed and shipped straight to your waiting feet!

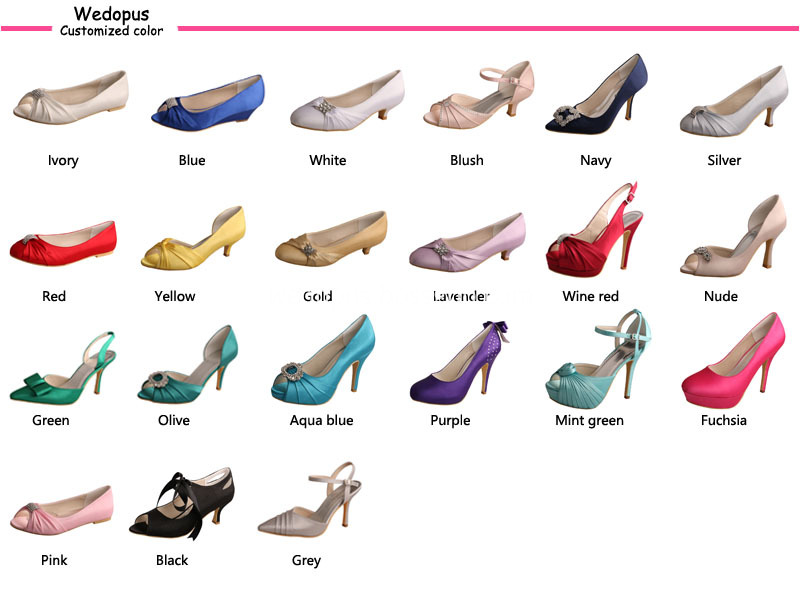

Custom made shoes with your choice of color design and heel size; Exquisite materials like crystals, bows, flowers and jewelled trims. There are lots of sleek designs of women`s shoes that have many colors out there. Well, nearly every style you opt for will have a medium, wide, and narrow option in any way the footwear brand sites. High quality and affordable price guaranteed.

Model Number: MQW-705

Upper: Lace

Lining: PU

Outsole: Rubber

EUR Size: 34~42; US Size: 4~11

Heel Height: 10cm

Sample Production Time: 7~10 Days

Order Production Time: 20-30 Days after Confirm Details

We provide free poly bag for each unit of bridal shoes lace, moreover, customized cloth bags and boxes are also available as customers' request.

If you have your own design,please send email. We can make your design, put your brand, make your own packing include box. We ship to worldwide, wholesale business are welcomed!

Related Keywords