Oil-Resistance Nylon Braid TS16949 TPU Auto Cable

- Payment Type:

- T/T, Western Union, Cash

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 10000 Meter

- Min. Order:

- 10000 Meter

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Yantian Shenzhen, Shekou Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,Guangdong |

|---|---|

| Productivity: | 5000000 M/Month |

| Supply Ability: | 500000 M/Week |

| Payment Type: | T/T,Western Union,Cash |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | TS16949;ISO13485;ISO9001 |

| HS Code: | 85441100 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Yantian Shenzhen,Shekou Shenzhen |

The 7-conductor PUR cables are used for star-delta circuits.

They are particularly suitable for use in mechanical systems, apparatus engineering, on production lines and in assembly equipment.

Oil-Resistance Nylon Braid TS16949 TPU Auto Cable

-

Oil-resistance tpu auto cable

-

Nylon braid tpu auto cable

-

TS16949 TPU Auto cable

Main Industry Application Products

- Bone Conduction Transduer

-

Speed Sensor;Angle Snesor;Temperture Sensor;Urea Sensor

- CNC Equipment Robot Arm

-

AED;Electrocardiograp

Description of Senkin Oil-Resistance Nylon Braid TS16949 TPU Auto Cable

- Conductor structure: see common conductor structure table or customization

- Insulation : TPEE/FEP/MPPO/TPV/PP/HDPE

- Sheath material : general with polyester type TPU or polyether type TPU

- Working temperature : -60 ℃--250 ℃

- Production range: standard section 0.03-6 square meter or customization

- Multiple conductors: 1-37 conductors or customization

Feature Of Oil-Resistance Nylon Braid TS16949 TPU Auto Cable

- Flexibility

- Elasticity (Spring Elongation Length Can Reach The Original Length Of 3 to 10 Times)

- Cold Resistance

- Flame Retardant

- Oil Resistance

- Abrasion Resistance.

Products Application:Oil-Resistance Nylon Braid TS16949 TPU Auto Cable

Products Application: Oil-Resistance Nylon Braid TS16949 TPU Auto Cable

Products Application: Oil-Resistance Nylon Braid TS16949 TPU Auto Cable

Specification

| P/N | Normal Spec. | Twisting OD | Resosyamce/KM | Standard OD | Conductor(Option) | Filling(Option) |

| 10 | 105/0.2541/2.588 | 2.588 | <5 | 3.2 |

99.99% Copper Tinned Copper Varnished Wire Sliver-Plated Copper Nickel Copper |

Kevlar/Nylon |

| 12 | 65/0.254 1/2.05 | 2.05 | <7 | 2.65 | Kevlar/Nylon | |

| 14 | 41/0.254 1/1.63 | 1.63 | <10 | 2.2 | Kevlar/Nylon | |

| 16 | 26/0.254 1/1.29 | 1.29 | <15 | 1.9 | Kevlar/Nylon | |

| 18 | 41/0.16 165/0.08 105/0.11 | 1.02 | <25 | 1.6 | Kevlar/Nylon | |

| 20 | 20/0.16 110/0.08 70/0.1 | 0.81 | <35 | 1.4 | Kevlar/Nylon | |

| 22 | 17/0.16 65/0.08 41/0.1 | 0.64 | <55 | 1.2 | Kevlar/Nylon | |

| 24 | 26/0.1 41/0.08 120/0.05 | 0.58 | <90 | 1 | Kevlar/Nylon | |

| 26 | 7/0.16 24/0.08 65/0.05 | 0.48 | <125 | 0.9 | Kevlar/Nylon | |

| 28 | 11/0.1 19/0.08 45/0.05 | 0.38 | <210 | 0.85 | Kevlar/Nylon | |

| 30 | 7/0.1 19/0.06 28/0.05 1/0.3 | 0.3 | <320 | 0.7 | Kevlar/Nylon | |

| 32 | 1/0.254 7/0.08 18/0.05 | 0.2 | <500 | 0.55 | Kevlar/Nylon | |

| 34 | 1/0.2 7/0.06 | 0.2 | <560 | 0.45 | Kevlar/Nylon | |

| 36 | 1/0.16 7/0.05 | 0.16 | <870 | Kevlar/Nylon | ||

| 38 | 1/0.127 7/0.04 | 0.12 | <1400 | Kevlar/Nylon | ||

| 40 | 1/0.08 | 0.08 | <3500 |

Kevlar/Nylon |

Specification

| P/N | Normal Spec. | Twisting OD | Resosyamce/KM | Standard OD | Conductor(Option) | Filling(Option) |

| 10 | 105/0.2541/2.588 | 2.588 | <5 | 3.2 |

99.99% Copper Tinned Copper Sliver-Plated Copper Nickel Copper |

NO |

| 12 | 65/0.254 1/2.05 | 2.05 | <7 | 2.65 | NO | |

| 14 | 41/0.254 1/1.63 | 1.63 | <10 | 2.2 | NO | |

| 16 | 26/0.254 1/1.29 | 1.29 | <15 | 1.9 | NO | |

| 18 | 41/0.16 165/0.08 105/0.11 | 1.02 | <25 | 1.6 | NO | |

| 20 | 20/0.16 110/0.08 70/0.1 | 0.81 | <35 | 1.4 | NO | |

| 22 | 17/0.16 65/0.08 41/0.1 | 0.64 | <55 | 1.2 | NO | |

| 24 | 26/0.1 41/0.08 120/0.05 | 0.58 | <90 | 1 | NO | |

| 26 | 7/0.16 24/0.08 65/0.05 | 0.48 | <125 | 0.9 | NO | |

| 28 | 11/0.1 19/0.08 45/0.05 | 0.38 | <210 | 0.85 | NO | |

| 30 | 7/0.1 19/0.06 28/0.05 1/0.3 | 0.3 | <320 | 0.7 | NO | |

| 32 | 1/0.254 7/0.08 18/0.05 | 0.2 | <500 | 0.55 | NO | |

| 34 | 1/0.2 7/0.06 | 0.2 | <560 | 0.45 | NO | |

| 36 | 1/0.16 7/0.05 | 0.16 | <870 | NO | ||

| 38 | 1/0.127 7/0.04 | 0.12 | <1400 | NO | ||

| 40 | 1/0.08 | 0.08 | <3500 |

NO |

Shenzhen SenKin Electronic Co.,major products are Silicone Cable/PTEE Cable/PUR /TPU Cable which used in the Auto,Sensors,High temperature resistance which use in Special Industry,Military Industry,Medical Industry,Robot Industry,Aerospace Industry with the monthly turnout of 500,000 meters.We handle tooling,production and packaging with the use of our eight production lines,supported by 150 staff members in our 2500 sqm factory.Our resources including production equipment and testing facilities from Taiwan and Japan enable us to turn out up to 500,000 meters monthly and provide major professional OEM service.

FAQ:

Q: Where Is Your Factory Located In?

A: Our Factory Located In Shenzhen City,Near to Shekou Port or Yantian Port

Q: What Can You Do For Client?

A: 1. Provide Very Useful And Professional Solution For Client's Request

2. OEM According With Client's Drawing or Design

3. 100% Quality Inspect

Q: What Is Your Payment Way?

A: We Accept T/T,Cash,Westerm Union And L/C

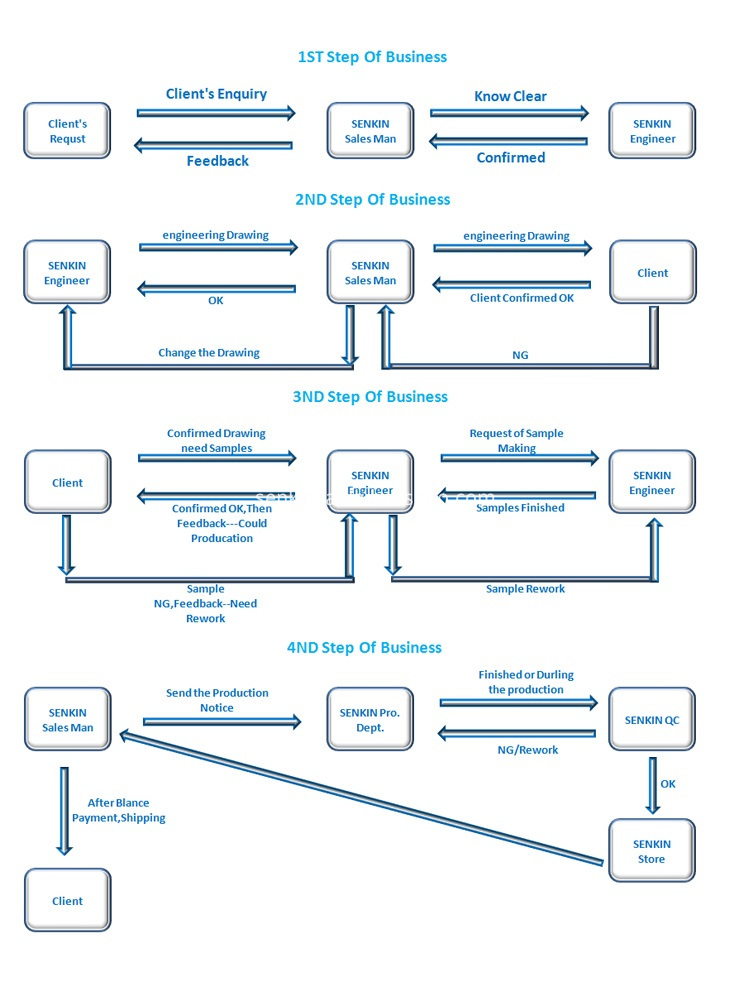

Q: What's The Business Step With Your Factroy?

A: Pls Feel Your Free Time To See The Below Info:

We provide shipping by sea,shipping by air,shipping by train,shipping by truck and express.

All the way will be choosed by client.

All Details if you cannot understand very well pls feel your free time to contact the sales man online by Skype or by Email.

Related Keywords