Organic waste gas treatment equipment

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 5 Days

- Transportation:

- Ocean

- Port:

- Shenzhen, Guangzhou, HongKong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 10000Sets |

| Supply Ability: | 100000 |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| Certificate: | CE |

| Transportation: | Ocean |

| Port: | Shenzhen,Guangzhou,HongKong |

Product Description

Product Description

Organic waste gas treatment equipment (adsorption + condensation) adopts the combination of adsorption and condensation methods to treat organic waste gas. The advantages of both are highly effective in purification efficiency, and their disadvantages are transformed to be available. The regeneration treatment of adsorbents USES low-temperature water vapor to desorption, recovers the activity of adsorbents, and recycles the organics that are desorbed. This is a relatively advanced treatment method for the purification of organic waste gas.

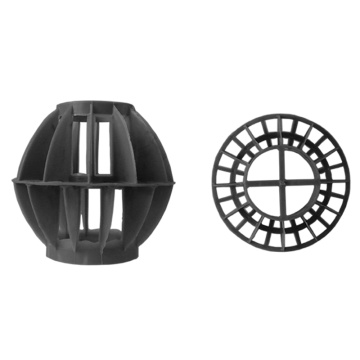

Activated carbon adsorption unit

The organic waste gas treatment equipment is suitable for purifying the organic waste gas at room temperature, medium and low air volume and medium and high concentration. The organic solvents that can be treated include benzene, ketones, lipids, alcohols, aldehydes, ethers, alkanes and their mixtures.

The device can be used in furniture industry, petrochemical industry, coal chemical industry, artificial leather, textile printing and dyeing, paint coating, rubber, plastics, shoemaking, pharmacy, electronics, chemical fiber, brewing and other industries.

The organic waste gas treatment process can be divided into three stages:

1. Use granular or fibrous activated carbon to fully adsorb molecules of organic components in waste gas, and stop the adsorption when a certain degree of saturation is adsorbed;

2. At the beginning, the activated carbon is activated by gasification and released from the activated carbon by heating the saturated activated carbon with saturated low-pressure water vapor. The reactivated activated carbon can readsorb the gas molecules of organic components.

3. The final stage is to condense the gas of the organic components which have been removed, make it liquefy, and automatically stratify it with water and then reuse it.

The technology of activated carbon adsorption device is mature and reliable.

Easy operation, energy saving and labor saving;

High performance adsorbent, large surface area, good absorption and desorption performance, high purification efficiency;

When the air flow temperature in the system exceeds the normal temperature by 120oC, the system is equipped with a vent valve, which can work according to the automatic safety program of the system to realize the air flow emptying until the connection of the adsorption bed is cut off and the process of adsorption and desorption is terminated.

Activated carbon adsorption unit

The organic waste gas treatment equipment is suitable for purifying the organic waste gas at room temperature, medium and low air volume and medium and high concentration. The organic solvents that can be treated include benzene, ketones, lipids, alcohols, aldehydes, ethers, alkanes and their mixtures.

The device can be used in furniture industry, petrochemical industry, coal chemical industry, artificial leather, textile printing and dyeing, paint coating, rubber, plastics, shoemaking, pharmacy, electronics, chemical fiber, brewing and other industries.

The organic waste gas treatment process can be divided into three stages:

1. Use granular or fibrous activated carbon to fully adsorb molecules of organic components in waste gas, and stop the adsorption when a certain degree of saturation is adsorbed;

2. At the beginning, the activated carbon is activated by gasification and released from the activated carbon by heating the saturated activated carbon with saturated low-pressure water vapor. The reactivated activated carbon can readsorb the gas molecules of organic components.

3. The final stage is to condense the gas of the organic components which have been removed, make it liquefy, and automatically stratify it with water and then reuse it.

The technology of activated carbon adsorption device is mature and reliable.

Easy operation, energy saving and labor saving;

High performance adsorbent, large surface area, good absorption and desorption performance, high purification efficiency;

When the air flow temperature in the system exceeds the normal temperature by 120oC, the system is equipped with a vent valve, which can work according to the automatic safety program of the system to realize the air flow emptying until the connection of the adsorption bed is cut off and the process of adsorption and desorption is terminated.

Related Keywords

Related Keywords