Medical Devices Plastic Injection Tooling

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 49 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

3K Mold offers a one stop solution from concept to production, from product to process engineering, turning your strategic projects into innovative applications.

For the injection moulding of thermoplastics, we are able to produce components with a maximum weight of 2500 grams (locking pressure up to 1500 tonnes), on state of the art equipment which is operated by highly-trained professionals.

Standard products are also part of our wide product range.

Project

Information

Product Description

Part name

Medical Devices Plastic Injection Tooling

Part Material

PC+ABS Sabic C2950HF

Part Size(mm)

390X282X28

Mould Description

Cavity Insert Material

738H

Core Insert Material

738H

Slider Insert Material

738H

Mould Cavities

1

Mold parts Standard

Hasco

Mold Size

900*750*700mm

Mold weight

1245 KG

Lead time

7 weeks

Mould Life Time (Shots)

50,000

Mould Type

Export to Italy

Runner Description

Cold runner

Injection Gate Type

Sub gate

Ejection System

Ejector pin

Slide Qty.

4

Lifter Qty.

0

Surface finish

matt VDI 3400 30-33

Injection moulding machine

380T

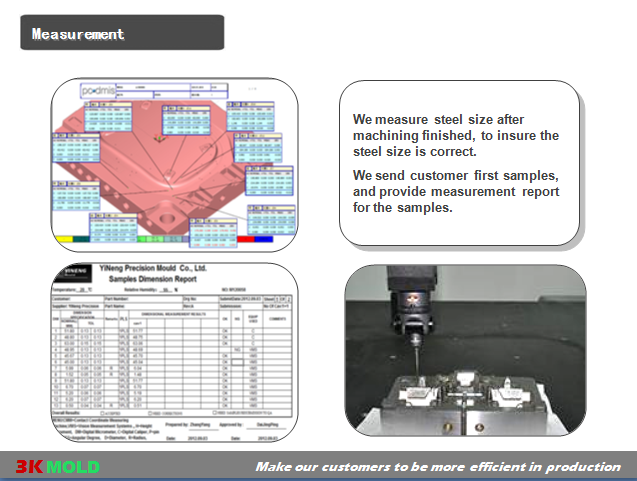

3K Mold is ISO-9001: 2008 certified. We use formal quality systems to manage the overall quality process and use precision measurement facilities by our well-trained team. All tooling and parts produced at our facility are constantly monitored by our Quality Assurance Department to meet your specifications.

Quality control Center

3K team committed to meet customer quality and delivery request. The main quality control process as following:

Incoming quality control (IQC)

In process quality control (IPQC)

Quality assurance (QA)

Quality management flow:

1. Mold base inspection

2. Steel inspection

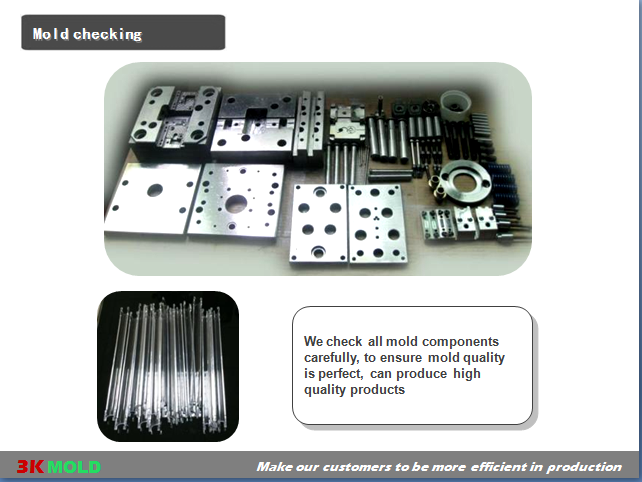

3. Mold component inspection

4. Electrodes inspection

5. Mold checking before assembly

6. (FAI, CPK) First Article dimension report

7. Mold checking before delivery

Related Keywords