Air Intake System Plastic Injection Moulding

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 35 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

3K Mold's engineering focus and capabilities provides customers with a partner who provides a positive impact on design considerations that effect the effectiveness and efficiency of the injection molding based production approach.

The 3K Mold team works with customers from the prototype stage, through the preproduction stage, and assists with and implements an efficient and effective production, logistics, and quality management process.

|

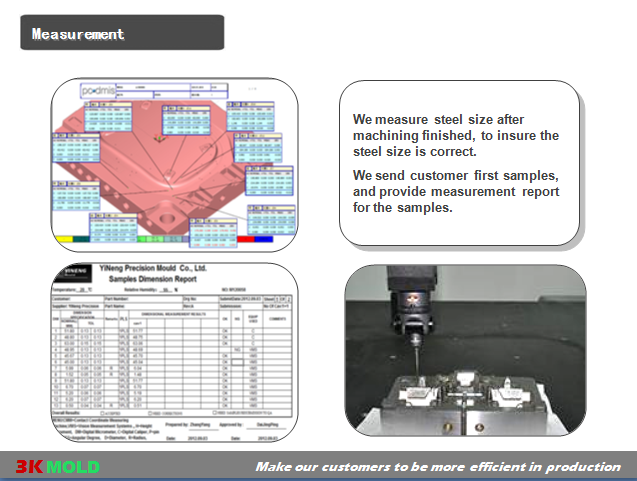

3K Mold is ISO-9001: 2008 certified. We use formal quality systems to manage the overall quality process and use precision measurement facilities by our well-trained team. All tooling and parts produced at our facility are constantly monitored by our Quality Assurance Department to meet your specifications.

Quality control Center

3K team committed to meet customer quality and delivery request. The main quality control process as following:

Incoming quality control (IQC)

In process quality control (IPQC)

Quality assurance (QA)

Quality management flow:

1. Mold base inspection

2. Steel inspection

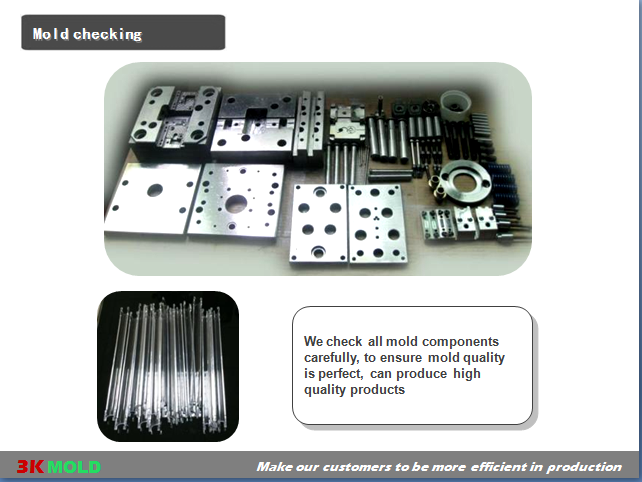

3. Mold component inspection

4. Electrodes inspection

5. Mold checking before assembly

6. (FAI, CPK) First Article dimension report

7. Mold checking before delivery

Related Keywords