Washing machine cover Injection TOOL

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 40 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

3K Mold is a plastic injection mould maker, located in Shajing Shenzhen, China, specializing 2K Plastic Injection Molds, multi-cavity plastic injection molds serving customers worldwide. 3K Mold has been in business for over 10 years. We create plastic injection molds for some of the world's largest manufacturers.

Our main business is Plastic Injection Mould Making, ability to create high-volume plastic injection molds to assure manufacturers of the lowest possible production cost, is legendary.

You've probably used a product from a plastic container we manufactured the injection mold for-

1. If you've used an Automotive, you've used a product molded in one of our plastic injection tools.

2. If you've used a Household Appliance, you've used a product molded in one of our plastic injection molds.

3. If you've used a Medical Device, you've used a product molded in one of our plastic injection moulds.

Please contact us today for your Plastic Products!!!

| Project Information | ||

| Product Description | Part Name | Washing machine cover Injection TOOL |

| Part Material | White ABS | |

| Part Size(mm) | 595*135*91 | |

| Mould Description | Cavity Insert Material | 1.2343 HRC50-52 |

| Core Insert Material | 1.2343 HRC50-52 | |

| Slider Insert Material | 1.2343 HRC50-52 | |

| Mould Cavities | 2 | |

| Mold parts Standard | Hasco | |

| Mould Life Time (Shots) | 1,000,000 | |

| Mould Type | Export to Poland | |

| Runner Description | Hot runner | |

| Injection Gate Type | Sub gate | |

| Ejection System | Ejector Pin | |

| Slide Qty. | 8 | |

| Lifter Qty. | 12 | |

| Injection moulding machine | 800T |

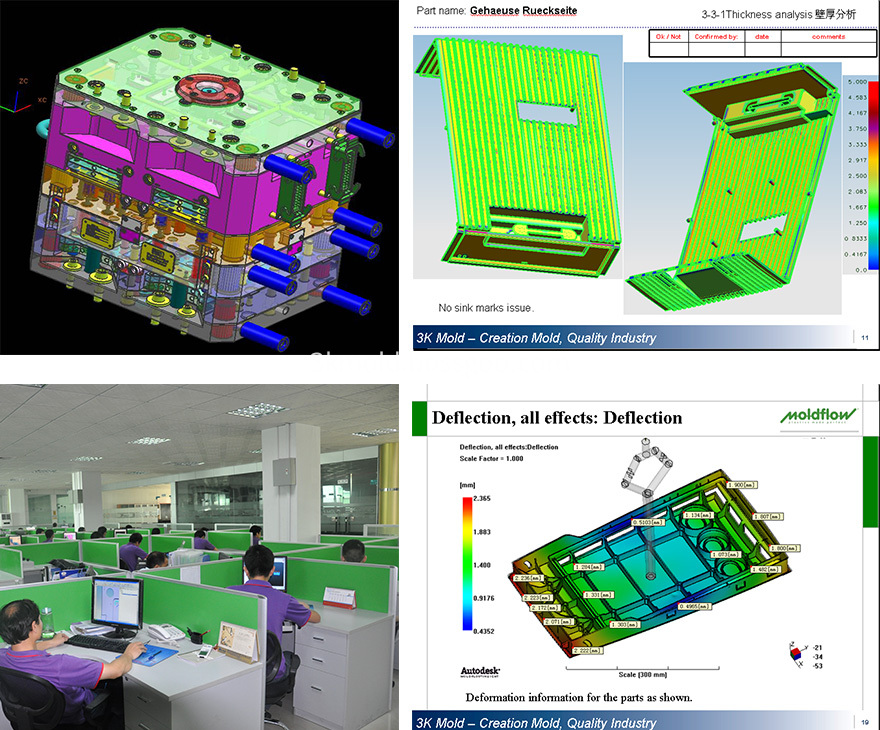

High quality mold starts with a high quality design.

Before mold machining, Engineering will provide a DFM report to analysis potential issue such as injection gate type and position, Mold layout, Ejector pins layout, draft analysis, thickness analysis, part warpage, sink marks and surface finish etc. If necessary, We also provide the mold flow analysis report to analysis the filing, pressure, weld line, airtrap, deflection etc. To discuss with customer and determine the final mold concept. After providing the 3D/2D for final approval.

At 3K Mold Group, our design team consists of 15 skilled designers. They knew Hasco, DME and Custom standard etc Europe andAmericamold standard very well. Equipped with the latest hardware and software CAD, CAE,CAMto assist mold design and manufacturing. Rely on advanced equipment and 20 years experience in mold industry. 3K Mold Group has been built a diversified customer base from different industry.

Related Keywords