Mower Housing Injection Moulding

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 35 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

A basic Procedure required for Any Mould development to meet the requirements-3K MOLD has own project management system, you can check any process under the project running.

Mould making flow chart:

1.Receive drawings from customer

2.Mould design and Approvals

3.Release drawings to Tool room

4.Raw material procurement

5.Process planning<Machining plan, Core-cavity plan, Electrode plan etc->

6.Procure Standard parts like Ejectors, Lifters, Springs etc..

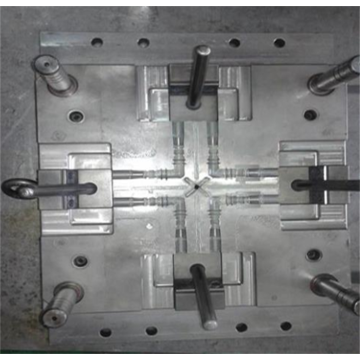

7.Check core-cavity Cut bearing areas(blue matching), Sliders pockets, Local Inserts etc..

8.Stage inspection for all parts especially main assembly parts like core, cavity, Inserts, electrodes, Sliders, guides, Wedges etc-

9.Ejector Assembly

10.Main Assembly

11.Trail-1

12.Polishing

13.Corrections/Modifications

14.Final Sample and Approvals

| Project Information | ||

| Product Description | Part Name | Mower Housing Injection Moulding |

| Part Material | PA 66 30GF | |

| Part Size(mm) | 288*286.5*85 | |

| Mould Description | Cavity Insert Material | 1.2343 ESR HRC50-52 |

| Core Insert Material | 1.2343 ESR HRC50-52 | |

| Slider Insert Material | 0 | |

| Mould Cavities | 1+1 | |

| Mold parts Standard | Hasco | |

| Mould Life Time (Shots) | 1,000,000 | |

| Mould Type | Export to Germany | |

| Runner Description | Hot runner | |

| Injection Gate Type | Sub gate | |

| Ejection System | Ejector Pin | |

| Slide Qty. | 0 | |

| Lifter Qty. | 0 | |

| Injection moulding machine | 500T |

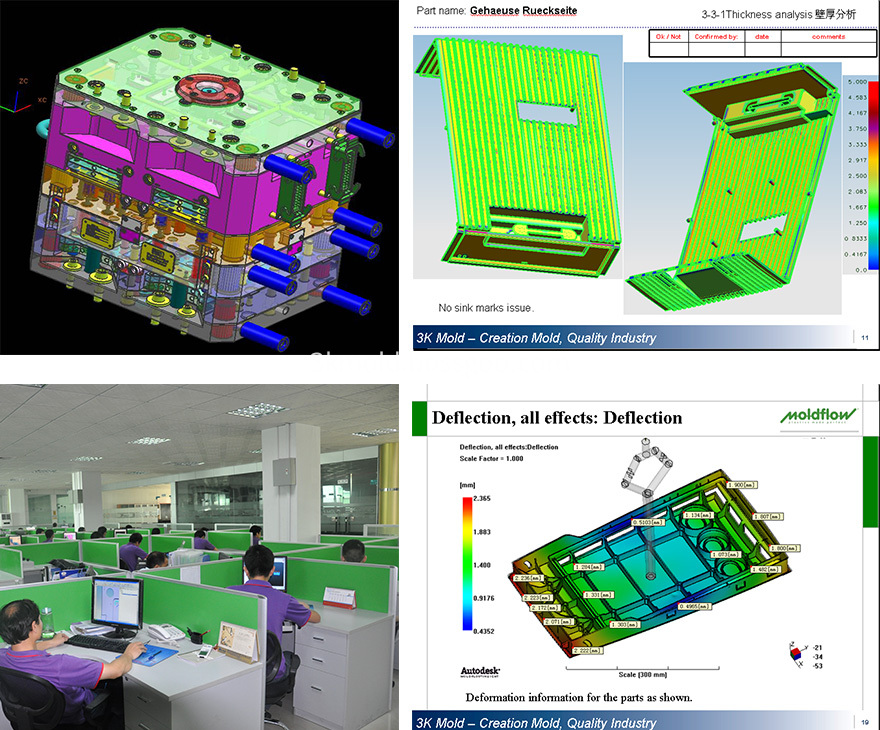

High quality mold starts with a high quality design.

Before mold machining, Engineering will provide a DFM report to analysis potential issue such as injection gate type and position, Mold layout, Ejector pins layout, draft analysis, thickness analysis, part warpage, sink marks and surface finish etc. If necessary, We also provide the mold flow analysis report to analysis the filing, pressure, weld line, airtrap, deflection etc. To discuss with customer and determine the final mold concept. After providing the 3D/2D for final approval.

At 3K Mold Group, our design team consists of 15 skilled designers. They knew Hasco, DME and Custom standard etc Europe andAmericamold standard very well. Equipped with the latest hardware and software CAD, CAE,CAMto assist mold design and manufacturing. Rely on advanced equipment and 20 years experience in mold industry. 3K Mold Group has been built a diversified customer base from different industry.

Related Keywords