BRACKET Plastic Injection Moulding

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 50 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

The soul of a successful enterprise is Human, we think the starting point of transcendence is from speciality,the wonderful initiative is from every creative people of dream and dedication.3K Mold has a professional mould design team, who are different education background and design experience to make 3K group more energetic and connotation, the different design idea integrate here, and collision, to inspire the working enthusiasm continuously. we keep moving,and have a powerful sound, we are continuous innovation, including passion, that making only one purpose, is to provide high quality mould for customers.

The engineering dept of 3K Mold adopt professional CAD,CAM and moldflow system, on the management which implemented planning,practice,examination and improved PDCA working process, to be " serious.careful.rigorous" for our job.

At the beginning of the project started, the engineer should review technical points and suggestions with customer, then provide a professional DFM to customer,after getting the response from the customer, to start mould 2D/3D,till getting the final approval, therefore, to ensure the customer can control the project started and engineering design completed in line with the actual needs of customers.

The engineering team of 3K Mold are master of DME.HASCO,MUSUMI,PROGRESSIVE,STRACK,MEUSBURGER,AGATHON,CUMSA standard applications, who often design big size injection mold, precision injection mold, rapid tooling, double injection mold, die casting mold, and (BMC) thermoset mold, MUD standard of DME specifications, the Blocking mode with HASCO standard, and according to the characteristics of customer products to customized mold system. the product scope are Automotive components,Car Electronic Devices,high qaulity Household appliances,consumer electronics, cosmetic and medical devices.

Mold flow analysis techniques, thermal balancing technology are of universal used in mold design,hot runner technoligy and gas-assisted injection molding technology are provided to what customers request.to make an independent mold system for customers.

" serious.careful.rigorous" of working can ensure customer's requirements,which ensures design are rationality, validity and accuracy,the feasibility DFM report (Design For Manufacturability) and mold flow analysis report for customers understand the structure of the parts, that influences the mould development,understood the mould basic design,learned some of the requirements and standards of molding. This can save much time for customer's new product development, but also to help customers to meet economic, efficient, reliable management requirements.

| Project Information | ||

| Product Description | Part Name | BRACKET Plastic Injection Moulding |

| Part Material | ABS | |

| Part Size(mm) | 285*192*104 | |

| Mould Description | Cavity Insert Material | 1.2343 HRC50-52 |

| Core Insert Material | 1.2343 HRC50-52 | |

| Slider Insert Material | 1.2343 HRC50-52 | |

| Mould Cavities | 1 | |

| Mold parts Standard | Hasco | |

| Mould Life Time (Shots) | 1,000,000 | |

| Mould Type | Export to Italy | |

| Runner Description | Hot runner | |

| Injection Gate Type | Open nozzle to sub gate | |

| Ejection System | Ejector Pin | |

| Slide Qty. | 1 | |

| Lifter Qty. | 2 | |

| Injection moulding machine | 400T |

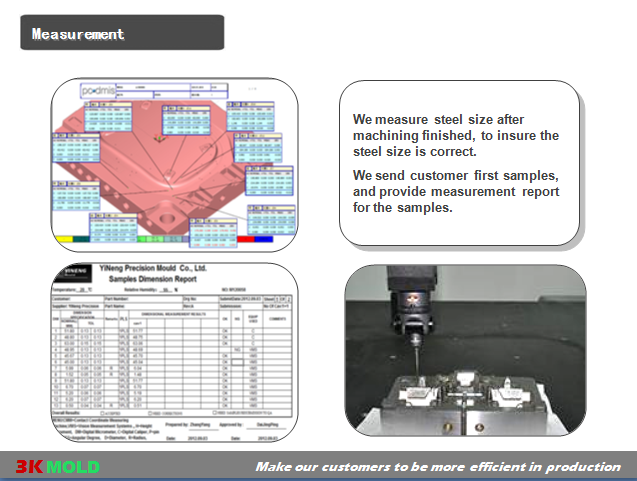

3K Mold is ISO-9001: 2008 certified. We use formal quality systems to manage the overall quality process and use precision measurement facilities by our well-trained team. All tooling and parts produced at our facility are constantly monitored by our Quality Assurance Department to meet your specifications.

Quality control Center:

3K team committed to meet customer quality and delivery request. The main quality control process as following:

Incoming quality control (IQC)

In process quality control (IPQC)

Quality assurance (QA)

Quality management flow:

1. Mold base inspection

2. Steel inspection

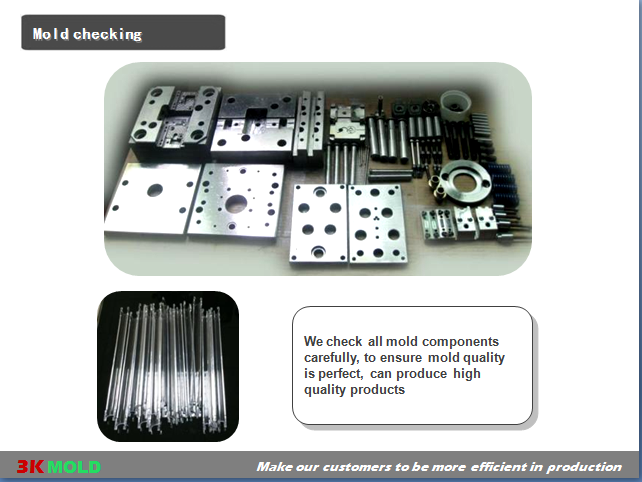

3. Mold component inspection

4. Electrodes inspection

5. Mold checking before assembly

6. (FAI, CPK) First Article dimension report

7. Mold checking before delivery

Related Keywords