2K Auto Injection Mold

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 42 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

In order to satisfy the design objectives of the client, 3K Mold follows the mould creation phases directly.

As a first step it uses simulation software to study and design different mould hypotheses. Once the design data, which ranges from the material selected to the mould that will be effectively used to make the parts, has been set, we can:

suggest the injection points to make figure filling easier;

highlight possible friction areas, or points where the material will run with difficulty;

identify the parts that cool prematurely, blocking the flow of the plastic.

3K Mold also uses the knowledge of specialised and make mould production in house.

After mould creation, particular attention is paid to the verification tests which precede the true component moulding phase, and corrections are made to any mould imperfections that may have been found as regards the design.

| Project Information | ||

| Product Description | Part Name | Double shot tooling |

| Part Material | PA66 and TPE | |

| Part Size(mm) | 148.6x98.5x22.5 | |

| Mould Description | Cavity Insert Material | H13 HRC 48-52 |

| Core Insert Material | H13 HRC 48-52 | |

| Slider Insert Material | ||

| Mould Cavities | 2+2 | |

| Mold parts Standard | Hasco | |

| Mold Size | 400X500X351mm | |

| Mold weight | 510kg | |

| Lead time | 6 weeks | |

| Mould Life Time (Shots) | 1,000,000 | |

| Mould Type | Export to France | |

| Runner Description | Mastip Hot runner | |

| Injection Gate Type | Hot tip directly to part | |

| Ejection System | Ejector pin | |

| Cycle time | 40S | |

| Slide Qty. | 0 | |

| Lifter Qty. | 0 | |

| Injection moulding machine | 350T |

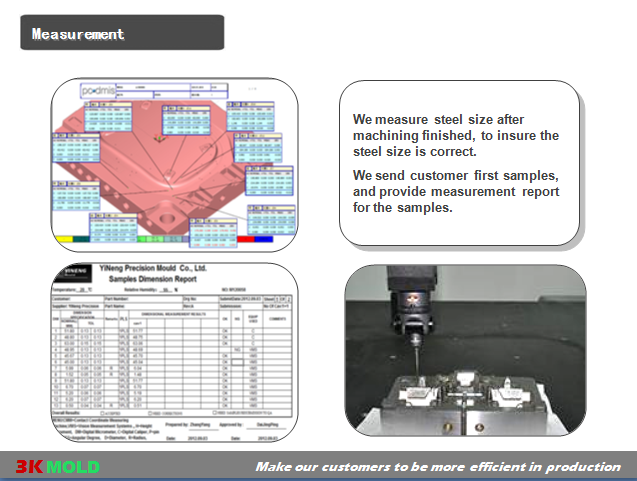

3K Mold is ISO-9001: 2008 certified. We use formal quality systems to manage the overall quality process and use precision measurement facilities by our well-trained team. All tooling and parts produced at our facility are constantly monitored by our Quality Assurance Department to meet your specifications.

Quality control Center

3K team committed to meet customer quality and delivery request. The main quality control process as following:

Incoming quality control (IQC)

In process quality control (IPQC)

Quality assurance (QA)

Quality management flow:

1. Mold base inspection

2. Steel inspection

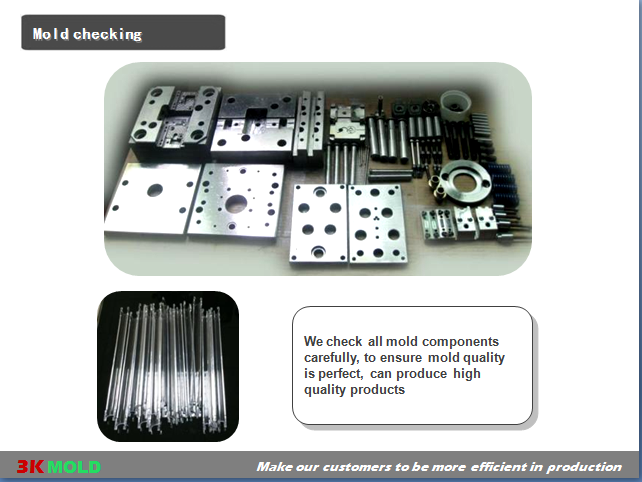

3. Mold component inspection

4. Electrodes inspection

5. Mold checking before assembly

6. (FAI, CPK) First Article dimension report

7. Mold checking before delivery

Related Keywords