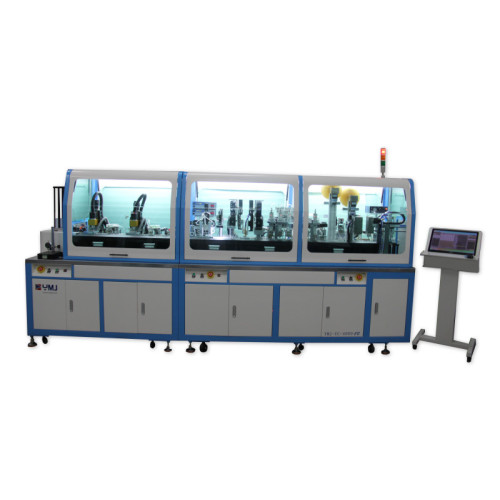

Dual Interface Card Milling and Embedding Two in One Machine

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 35set/year |

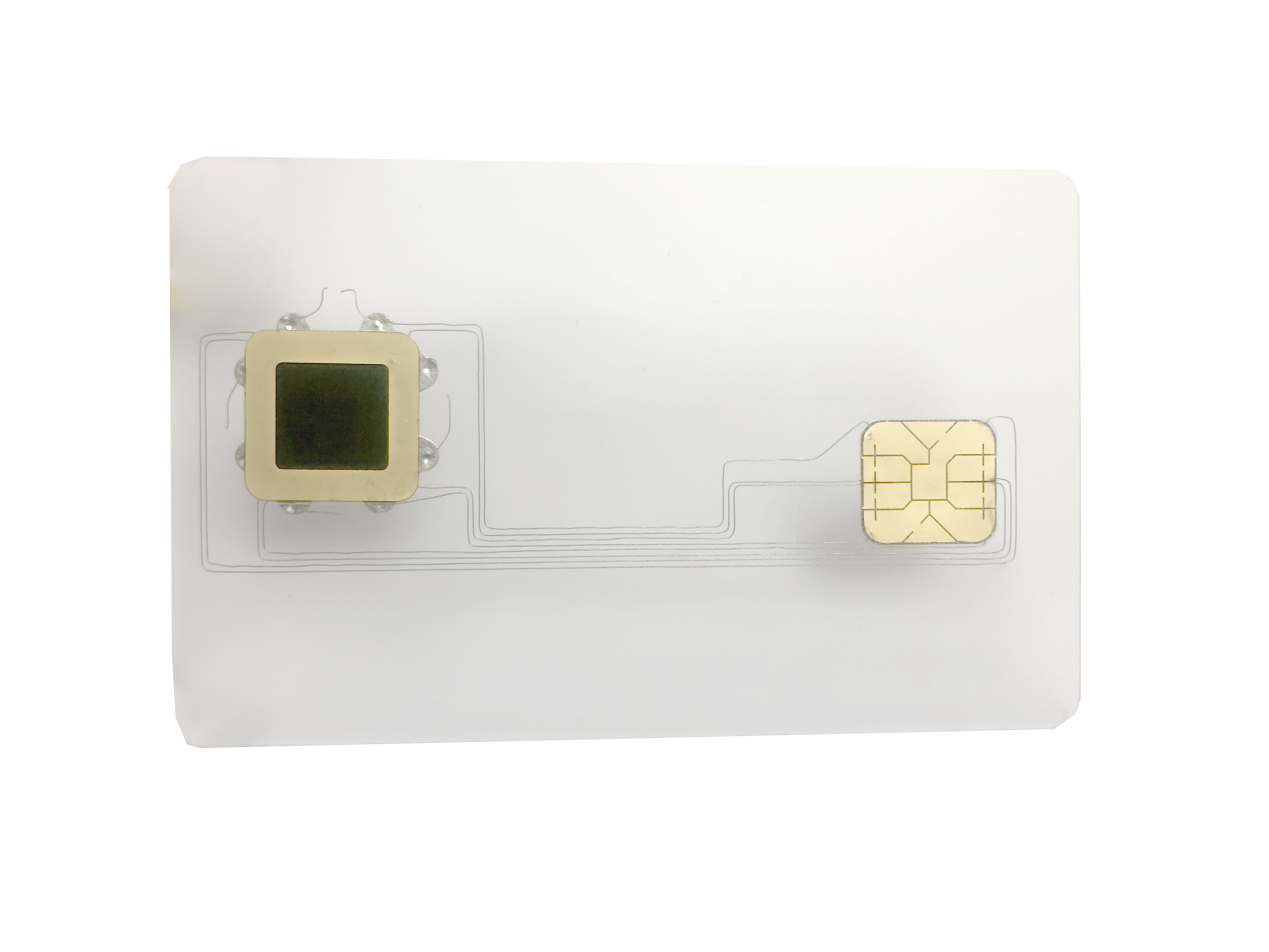

Dual interface card embedding machine used for conductive glue, tin paste, conductive glue tape, contact IC and coupling IC technology. Machine includes milling, suction cleaning, glue dispensing, pre-welding, module punching, embedding, OCR checking and bad card separate collecting functions.

Technical parameter:

Control:Industrial PC

Voltage:AC 380V 50 / 60 Hz 20A

Power:12 KW

Air Pressure:6㎏/C㎡

Speed:For DI card with tin technology is about 2500-2800cards/h

For DI card with conductive glue technology is about 3200 cards/h.

For normal card is about 4000 cards/h.

Dimension:(L)4220*(W)950*(H)1910 mm

Weight:3000kg

Module punching accuracy:+/-0.05mm

Milling position accuracy:+/-0.05mm

Milling depth:±0.015~±0.02mm

Milling size:±0.05mm

Embedding position accuracy:+/-0.05mm

Embedding Flatness accuracy:+0.05mm, -0.1mm

Embedding Head Temperature adjustment range:25℃~300℃

The temperature difference between the actual temperature of the welding head and the display temperature of the equipment are:Less than10℃

Temperature fluctuation range:+/-10℃

Applicable materials:Hot melt glue tape, Laminated strip module with ISO standard, 0.68~0.8mm thickness ISO lamination PVC, ABS card.

Operator:1 person

Pass Rate:99.8%

Equipped with machine:Vacuum Cleaner (one set) Chiller (one set)

Related Keywords