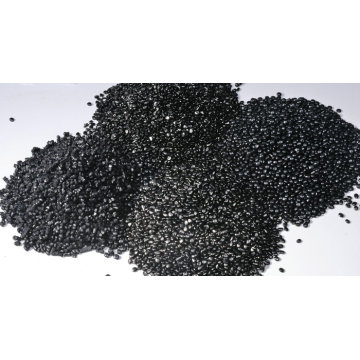

42% Carbon Black Masterbatch

- Payment Type:

- L/C, T/T, D/P

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 5 Ton

- Min. Order:

- 5 Ton

- Delivery Time:

- 10 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500kg/Hour |

| Supply Ability: | 500ton/Month |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | SGS |

| Transportation: | Ocean |

Description

This black masterbatch is well designed for PE/PP Injection Molding (Box, Containers, Chairs, Crates, Buckets, Battery, cases, Hangers, etc.), PE/PP Extrusion Molding (Sheet, Pipe, Wire & Cable, etc.), PE Blow Molding (Medical & Cosmetic container, Lubricant & Paint container, etc).

The 42% Carbon Black Black Masterbatch 9014 is one middle grade concentration black masterbatch, made with virgin PE carrier and high tint power pigment carbon black (ZY-1) and super fine CaCO3, polished by PE wax, have shiny surface and finish, the MFI is as high 15-18 gram/10 mintues 21.6kg &190 Cdegree. The 42% Carbon Black black masterbatch 9014 is one universal using products, and could be used for most thermal plastic hard resin production. The 42% Carbon Black Black Masterbatch is suitable for use in common injection, granulation, pressure sheet,extrution pipe. The 42% Carbon Black Masterbatch does not have any odor smell, compatiable with ABS, PC, PS, Nylon, PPM, PPS.

Composition

Carbon Black Content=42%±1%

Carrier=Virgin LDPE

Carbon Black =high tint power pigment carbon black(ZY-1)

Calcium Carbonate= 1200mesh

Compatiable Applications

The 42% Carbon Black Black Mastebatch 9014 is compatible with ABS, PC, PS, Nylon, PPM, PPS. materials.

Method of Usage

The 42% Carbon Black Black Masterbatch 9014 has good dispersion ability and is therefore suitable for direct addition and mixing with plastic resins in mixer,avoiding pollution and mal-scattering problems caused by pigment.

Recommended Dosage

1-3% subjected to the final products requirements.

Physical Properties

Density(24℃) : 1,350kg/m3

Melting Flow Index : 15g/10min(21.6kg/190℃)

Moisture Content : <0.15%

Packaging And Storage

The 42% Carbon Black Black Masterbatch 9014 is supplied in pellet form and packed in 25kg plastic or paper bags.It should be stored in a dry place.

Related Keywords