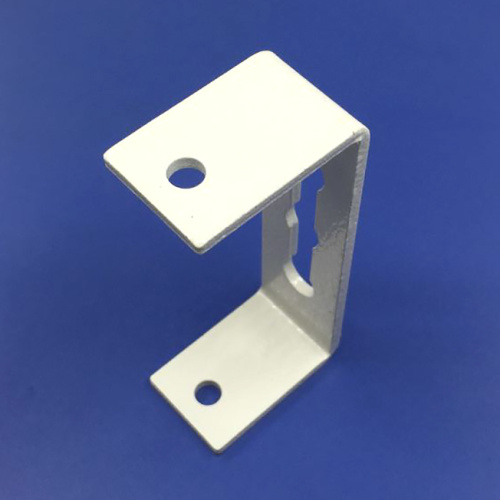

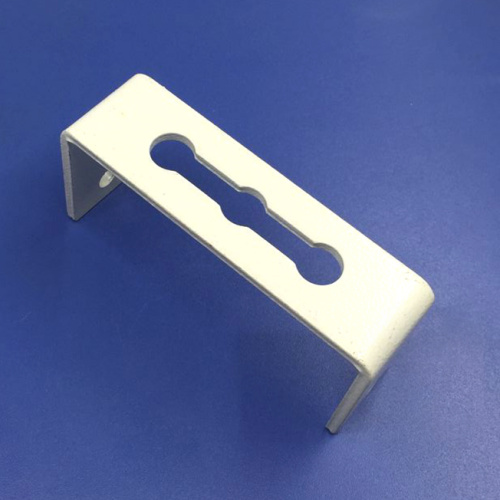

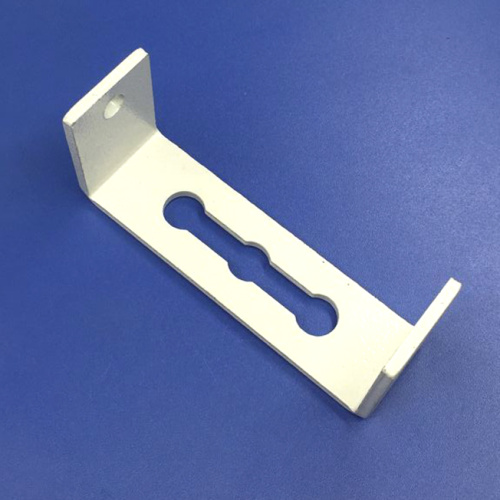

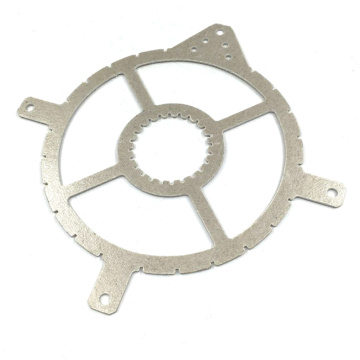

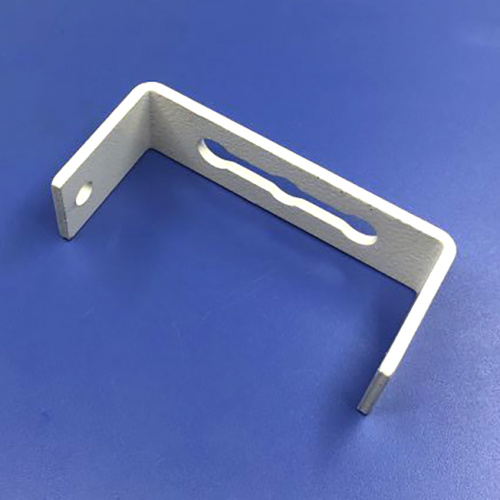

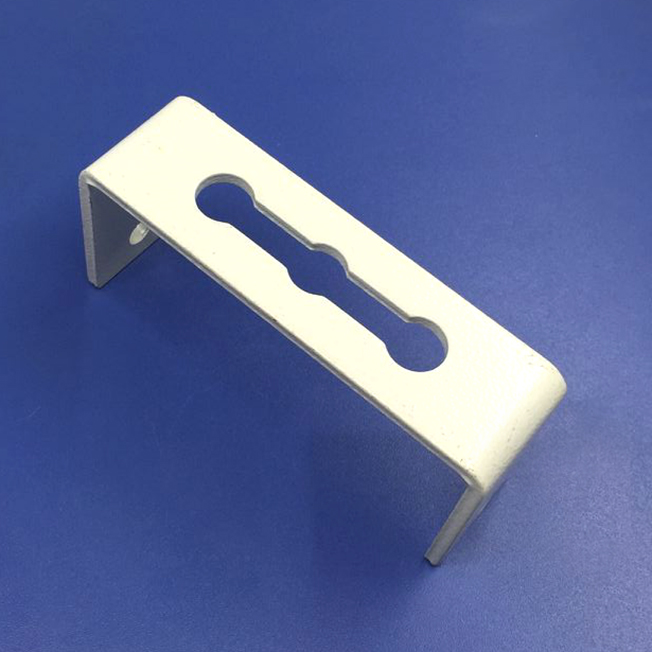

Custom Sheet Metal Fabrication

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 7800/Month |

|---|---|

| Transportation: | Ocean,Land,Air |

Sheet metal manufactuing is the use of sheet metal production of chimney, bucket, tank Youhu, ventilation pipe, elbow reducer, Tianyuandifang, funnel and so on, main process, bending, shear buckling edge bending forming, welding, riveting, requires a certain knowledge of geometry. Custom Sheet metal fabrication steps: product preliminary test, product processing trial production and product batch production. In the sheet metal manufacturing trial production step, should promptly communicate with the customer contact, get the corresponding processing evaluation, and then batch production. Custom sheet metal fabrication generally used materials are cold-rolled plate, hot-rolled plate, galvanized plate, copper, brass, beryllium copper, aluminum, stainless steel, according to different functions of the product, choose different materials, generally from product use and cost up to consider.

Our company is a professional precision parts manufacturing enterprises, the company strictly enforce the ISO quality management system to ensure quality, to undertake a single parts and bulk parts orders business. Major customers in the hardware, medical, shipbuilding, military, automotive, scientific laboratories and other fields. We offer industry-leading custom CNC turning and milling. Providing the best CNC turning and CNC horizontal / vertical milling. Our extensive range of state-of-the-art CNC lathes and CNC Turning machines meet the tolerances of ± 0.01mm. Through teamwork and fruitful communication, we optimize the management process, we attach importance to every customer, to ensure that each cnc machining turning parts of the quality and delivery.

|

Business content |

CNC miliing, CNC turning |

|

Machining Processes |

CNC Milling, CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threasing, Tapping, Drilling, Knurling |

|

Machining Metal |

Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM |

|

Parts Size |

Milling Parts ( MAX) : Length 1030mm,Width 800mm, Height 750mm. Turning Parts ( MAX) : Diamter 680mm,Length 750mm. |

|

Tolerance |

0.01mm |

|

Equipment Capabilities |

CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch |

|

Secondary Services of Machining Parts |

Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing |

|

Sample |

Samples are for free, sample time is 5 days. |

|

Delivery |

Delivery time is 3-4 week, depending on the degree of difficulty of machining parts |

|

file format |

Para-Solid 3D, PDF, IGES, STEP, SOLIDWORKS |

Related Keywords