Machining Aluminum Parts with Diamond Knurling Pattern

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 4600/Month |

|---|---|

| Transportation: | Ocean,Land,Air |

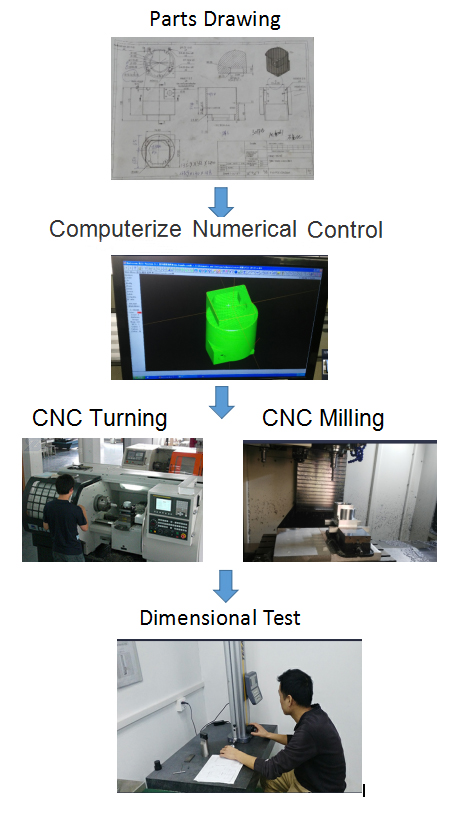

Machining Aluminum Parts with Diamond Knurling Pattern

The force of machining diamond knurling pattern on aluminum parts on a lathe is quite large, and the workpiece must be firmly clamped. When installing the knurling knives, the cutter face should be perpendicular to the workpiece and the center of the flower wheel should be aligned with the axis of the workpiece. When machining diamond knurling pattern on aluminum parts begins, the beginning is very important, it should be pressed directly into the workpiece emphatically, and should be no pause, to make the pattern on the workpiece at a draught . When the pattern is clear then feeding, otherwise, it is easy to produce pattern tumbling. When machining diamond knurling pattern on aluminum parts, make sure that there is sufficient lubricating fluid, which can be lubricated by mechanical oil, we should also regularly remove chips, so that the patterns on aluminum parts can be clear.

Buildre Group Co., Ltd is a professional manufacturer of CNC and CNC Machining Services and Molding Services for OEM and ODM parts. And through the ISO 9001: 2008 quality certification system, the production base is located in Shenzhen bright. CNC machining plant covers an area of over 2,600 square meters, the main production of CNC machining parts for medical, automotive, communications, electrical, electronics and other industries. Production types include CNC milling, CNC turning, grinding, stamping, bending, welding, die casting, drilling, tapping and injection molding. More than 46 CNC machining centers and CNC lathes for your service.

We provide high-precision machining services:

1 Machining process: CNC milling, CNC turning, sheet metal fabrication.

2 CNC machining range:Aluminum 6061, 6063, 6061-T6, 7075, 5052. 2017. 6083. Steel: Q215,Q235,10# 15#, 45#, S136, SKD11,718H. copper / bronze / Titanium / TC4. Plastic:Delrin POM, Teflon, Nylon, PA, PC, PMMA, Ultem, PEI, PTFE. Stainless steel: 303, 304, 316, 430, 420. Secondary Services Offered: laser engraving LOGO. Anodizing, Plating Chrome, Nickel, RoHS Zin, Etc.Assembly Welding, Heat Treating, Powder Coating, Centerless Grinding.

3 CNC machining equipment: cnc machining center, cnc turning center, engine lathe, drill press, milling machine, grind machine. CNC Machining Product Accuracy 0.01mm.

CNC Machining can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Related Keywords