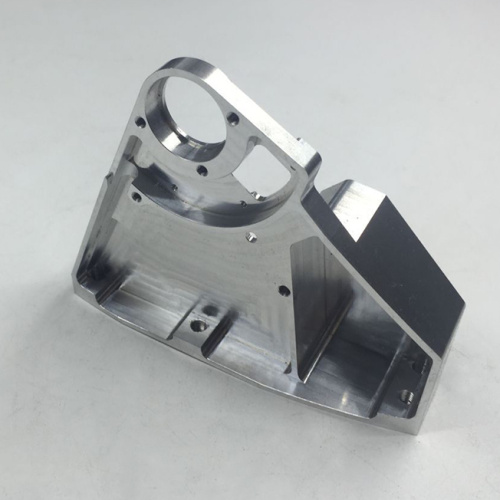

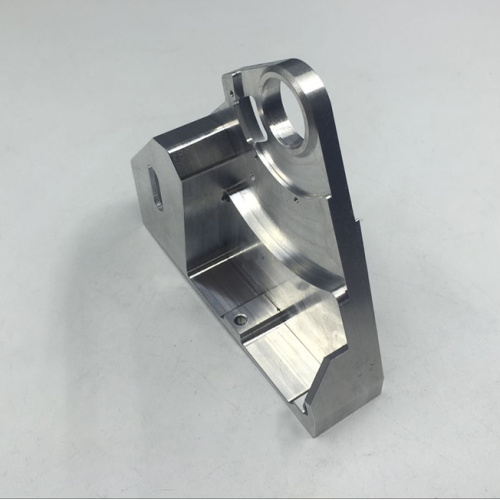

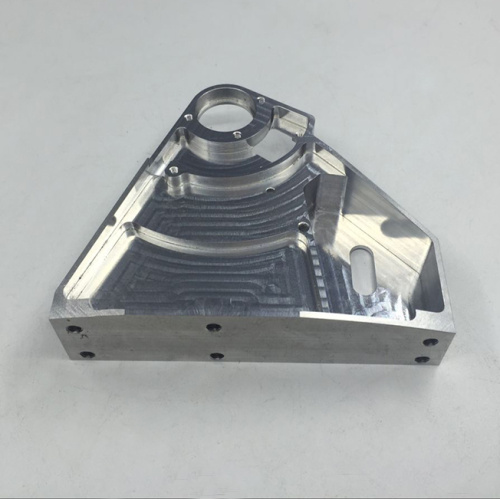

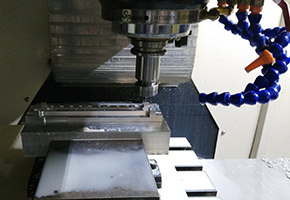

Five Axis CNC Milling Machining

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 4000/Month |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

Relative to the common three axis machining, five axis machining refers to the machining of complex geometry parts, the need to process tools can be five degrees of freedom positioning and connection. The machine tools adopted by five axis machining are usually called five axis machine tools or five axis machining centers. Five axis machining is commonly used in the aerospace field to machining airframe parts, turbine parts, and impellers with free curved surfaces. Five axis machine tools can machining the different sides of the workpiece without change the location of the workpiece in the machine tool, and can greatly improve the machining efficiency of prismatic parts.

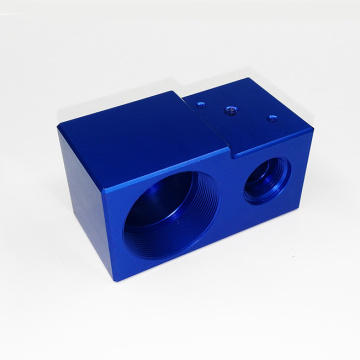

CNC machining including CNC milling and CNC turning, cunting, grinding, milling, sheet metal fabrication. CNC milling machining and CNC turnining materials are: Aluminum 6061, 6063, 6061-T6, 7075, 5052. 2017. 6082. Steel: Q235, 45 #, A3, 718H, S136, SKD11. Stainless steel: SUS303, SUS304, (1.4301), SUS316. copper / bronze. Plastic: POM, PA, ( PA66 ) PC, PMMA. Product surface treatment: anodise (clear, black, blue, yellow, can also customize a variety of colors). Sandblasting, spraying, passivation, laser engraving LOGO, silk screen LOGO.

We have more than 2,600 square meters building workshop. Has 12 years of experience in CNC milling machining and cnc turning, a dedicated technical team on the machining and CNC milling. These are: 8 with more than 10 years of work experience in programming, 12 more than 8 years of skilled workers. Has passed ISO9001: 2008 quality system certification. We have 46 CNC machine tools, these include: CNC machining center, CNC Lathe, Drill Press, 4 Axis machining, lathe, Milling Machine. Production of thousands of parts, serving many different industries, Including aerospace and medical, automotive parts, unmanned aerial vehicles, communications terminals and precision components such as robots, etc.

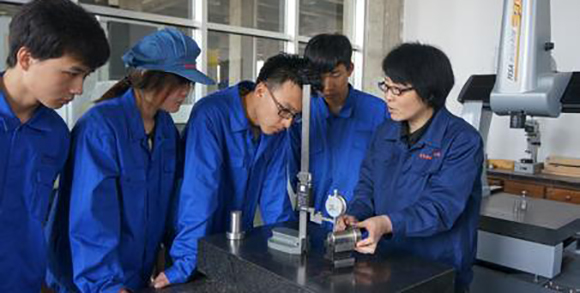

From the procurement of raw materials to CNC machining parts shipments, we have established a complete set of quality control system. The whole process of operating workers by SOP operations, IPQC products for each machining steps to detect, Make sure the product meets the requirements before proceeding to the next CNC milling machining. And 100% full-size inspection of the first machining part. FQC tests the product before shipping and ships the shipping report. Engineering and technical personnel on a regular basis for machining and maintenance settings, timely update machining tool. Our inspection tools are: Digital caliper, Micrometer Calipers, height gauge, Profile projector... Tolerances can be measured +/-0.01mm and 0.001mm.

Related Keywords